Government mandates for lower C02 emissions and consumer demand for vehicle electronics have resulted in a transition from 12 volt automotive systems to more efficient 48 volt architectures. These mid-voltage architectures offer higher power delivery and lighter, lower-cost wiring harnesses.

The problem for designers is ensuring that the connectors meet the demanding electrical, safety, reliability, and physical requirements of 48 volt systems while meeting cost and time-to-market constraints. The solution lies in developing an understanding of the operational, regulatory, and safety requirements of mid-voltage automotive architectures before choosing from an appropriate supplier’s selection.

This article reviews the benefits of 48 volt architectures and outlines the challenges of selecting appropriate connectors. It then presents suitable solutions from Molex and describes how these solutions may be applied in practical scenarios.

The benefits of 48 volt automotive architectures

Automakers can implement mild hybrid systems that recuperate energy during braking and coasting by moving to mid-voltage architectures. They can also deploy enhanced start-stop systems that reduce fuel consumption while city driving and in traffic jams. Additionally, because the higher voltage allows the use of lighter, smaller-gauge wires to deliver the same power at a lower current, 48 volt systems reduce vehicle weight. All these factors translate to significant fuel savings, particularly in smaller vehicles.

Higher-power wiring harnesses are also needed to accommodate the electrification of components such as power steering, air conditioning, and the adoption of advanced driver assistance systems (ADAS), such as adaptive cruise control and lane-keeping assist. Transitioning to a 48 volt architecture meets this need without the costs and complexities associated with the high-voltage systems (i.e., 400 volts and beyond) used in full hybrid electric vehicles (HEVs) and battery electric vehicles (BEVs).

The 48 volt architecture also serves as a bridge to greater vehicle electrification, allowing gradual integration of hybrid technologies without a complete electrical overhaul. These mid-voltage systems will remain valuable even in fully electric vehicles, as evidenced by their incorporation into designs like the Cybertruck.

Cost considerations for 48 volt connectors

The question of which electrical connection system should be used for 48 volt architectures can be answered by looking at the technical challenges arising from the increased voltage.

Adopting the high-voltage connectors developed for use in electric and hybrid vehicles is technically feasible, but cost and package-space considerations make it inadvisable. In contrast, adapting 12 volt connectors for mid-voltage architectures is an attractive cost and size proposition.

It is worth noting that not all vehicle systems will switch to 48 volts. Some smaller devices that consume less power will stay at 12 volts. Therefore, it is useful to have consistent connectors across 12 and 48 volt systems to simplify tooling and technician training.

Molex’s MX150 Mid-Voltage Connector System (Figure 1) exemplifies these design principles. These connectors share their form factors with the field-proven, low-voltage MX150 connectors. By using the same package size and housing design as the 12 volt connector system, the MX150 Mid-Voltage Connectors provide a straightforward upgrade to 48 volt wiring architecture with minimal design engineering.

Figure 1: Connectors from the MX150 Mid-Voltage Connector System share their form factors with the field-proven, low-voltage MX150 connectors. (Image source: Molex)

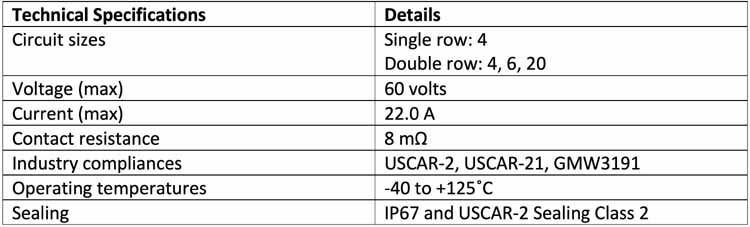

The MX150 Mid-Voltage Connector System currently encompasses five different configurations, as detailed in Table 1. These include the dual-row 33482 blade connectors and the corresponding dual-row 300361 receptacles, as well as the

single-row 300363.

Safety considerations for 48 volt connectors

Although 12 volts is a good starting point for mid-voltage connectors, the challenges in moving to 48 volts are not trivial. Arcing is of particular concern.

In 12 volt systems, small arcs typically extinguish quickly when circuits are broken. However, at 48 volts, arcs can persist longer, potentially causing severe damage to the terminals and housings. To mitigate this risk, terminals must be spaced adequately to meet creepage distance and clearance requirements as outlined in DIN EN 60664-1, which governs insulation coordination for equipment within low-voltage systems.

Creepage refers to the shortest path between two conductive points along an insulating surface, while clearance denotes the shortest air path between conductors. These specifications are crucial to ensure protection up to 60 volts, the upper limit of the overvoltage range.

Effective terminal secondary locking is also essential to prevent terminal push outs (TPOs), which can cause slow or intermittent power disconnects. Such disconnects may initiate micro-arcing, damaging the plating or compromising the terminal base metal, leading to high resistance or a welded connection.

Connector sealing also merits careful attention. Exposure of a 48 volt connector to an electrolyte such as salt water can trigger an aggressive electrochemical reaction, more so than at 12 volts. To prevent such damage and short circuits, it is crucial to use connectors that meet the appropriate pollution degree, typically USCAR-2 Sealing Class 2 or higher.

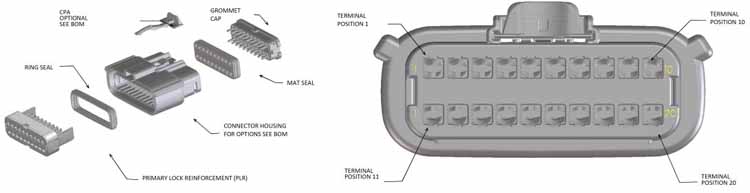

Figure 2 illustrates how these design principles are implemented in the 3003610011, a dual-row, mid-voltage female receptacle with twenty circuits. The corresponding male connector is the 0334822423.

The MX150 connectors are pre-assembled with connector housings, seals, and Terminal Position Assurance (TPA) components in place, streamlining installation and maintenance. Key features of the connector illustrated in Figure 2 include:

• A TPA that securely locks terminals into their housings, preventing dislodgment

• A secondary Connector Position Assurance (CPA) lock that ensures a secure connection and prevents accidental disengagement under severe vibration or shock

• Integral mat and ring seals that ensure safe performance even when submerged, eliminating the need for individual cable seals

• A grommet cap that enhances the protection of the mat seal and ensures the correct alignment of terminals, maintaining the integrity of connections

Mixed-voltage design considerations

Special precautions are essential in mixed-voltage systems to prevent current from flowing between mid-voltage and low-voltage circuits. The most effective strategy is to use separate connectors for each voltage level, avoiding the integration of both voltages within the same connector. Additionally, the automotive industry has adopted light blue color coding for 48 volt connectors to clearly differentiate them from 12 volt connectors.

The origin of this color coding dates back to electric forklifts, which have long used batteries of varying voltages. Color guidelines were established to prevent errors, leading to the widespread adoption of blue for 48 volt connectors across various industries.

This system works in tandem with the established use of orange connectors and wiring, which signify high-voltage systems. This color coding clearly indicates components that require specific safety precautions, ensuring that they are not handled without appropriate safety training and personal protective equipment (PPE).

Manufacture and serviceability considerations

The risk of arcing in mid-voltage connectors necessitates that they be designed for reliable manufacturing and servicing. This requirement is addressed by USCAR-21, which stipulates the test methods and criteria for cable-to-terminal electrical crimps in automotive applications.

A key aspect of USCAR-21 is pull testing, which involves applying a consistent pull rate to a crimped connection to assess its tensile strength. This testing ensures the crimp can endure the mechanical stresses it will face during its service life. The specification also highlights the necessity of using precise tooling and process settings during crimping.

Additionally, it is advisable to seek connectors certified to GMW3191, a comprehensive standard formulated by General Motors. This standard outlines the testing and validation requirements for automotive electrical connectors, confirming their reliability and durability in demanding conditions.

Molex MX150 assembly and service considerations

To complete a connector assembly, the wiring must first be terminated. With the MX150 male connector assembly, for example, the wire harness must be terminated into a 330000001 blade. Similarly, the wiring must be terminated into a 33001 or 33012 series rectangular connector contact for the female receptacle.

In either case, the terminated wires must be pushed into the connecter until they are secured. If a circuit position must be left empty, the gap should be filled on the male side with the 343450001 cavity plug.

To aid in this termination process, Molex offers the 0638115900 manual crimping tool (Figure 3). This device ensures a secure connection between the wire and blade or rectangular contact.

Specialized equipment is also available to service a connector. The 0638131500 extraction tool (Figure 4) allows technicians to remove wires from a connector without disturbing the rest of the assembly.

Conclusion

When transitioning to a mid-voltage architecture, automakers and their suppliers can benefit from using components based on low-voltage technology. The move to 48 volts presents new safety and reliability concerns, but these concerns can be readily addressed by careful attention to standards and choosing a connector system incorporating robust locking and sealing mechanisms. When selecting a 48 volt connector system, it is advisable to seek a vendor with a comprehensive portfolio, proven experience, and associated tooling.