Page EEPROM for asset tracking? Yes, indeed! A lot of companies with great assets are tracking how Page EEPROM is on track to transform asset tracking. While the phrasing is cheeky, the phenomenon is quite real. A couple of studies published just a few months ago both anticipate EEPROMs to exceed one billion dollars by 2030. Interestingly, both reports cite ST as a leading player, noting how innovative EEPROMs are driving this growth. Put simply, Page EEPROM is responsible for massive transformations in numerous industries, like medical devices and hearing aids. Let us, therefore, explore why this memory is gaining ground in asset tracking systems and what engineers should know to ensure that they stay ahead of this new trend.

What makes asset tracking special?

Asset tracking applications must deal with unique challenges because they often have an abnormally long lifespan. In many cases, the asset tracker doesn’t regularly return to a base. In some cases, it never does. Hence, changing a battery or physically accessing a terminal to update its firmware can be a real problem. Consequently, systems must not only be small and consume little power because they operate on batteries but also last five to ten years, and sometimes more. Hence, every microamp counts. Similarly, the memory must be robust and have enough endurance to survive hundreds of thousands of read-write cycles because their lifespan is so long.

What makes Page EEPROM unique?

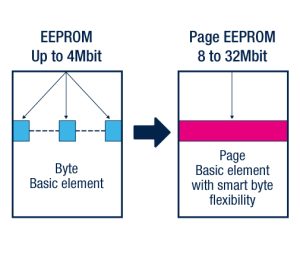

Avid readers of the ST Blog already know that ST’s Page EEPROM solves many of these issues with its ultra-low power consumption of 500 µA in read operations, its high data rate of 320 Mbit/s, and its high endurance of half a million read-write cycles per page. Thanks to its hybrid architecture, which uses 16-byte words and 512-byte pages while still enabling byte-level write operations, the Page EEPROM retains the flexibility and robustness of traditional EEPROMs while offering capacities and speeds on par with Flash. This unique structure also explains why ST is at the forefront of the EEPROM expansion, as Page EEPROMs can now serve applications that would have had to use Flash.

Consequently, Page EEPROM is often found in data logging applications and used for firmware management. Traditionally, engineers use EEPROM to log a lot of small data, like sensor information, due to its byte-level architecture. However, the memory itself lacks speed. Conversely, firmware management needs speed as it usually entails a large data transfer but doesn’t require the same granularity. Thanks to Page EEPROM, integrators get the best of both worlds, which means that they can use one time of memory for more applications, thus getting a better return on their investment.

What asset tracking applications do most often?

However, when an application like asset tracking must last a decade in the field, an application needs more than low power consumption. Tracking assets comes with the unique technical consideration that the system spends most of its time asleep. Indeed, the MCU will only wake up at specific intervals, and the external memory is active for only a short while to record information before adopting the lowest power mode possible. As a result, the power consumption during those off times is even more critical, and the time the memory takes to boot up is also a key factor because it will affect how long the system stays awake and thus consumes more energy.

What difference does a 30 µs power-up time make?

Page EEPROM is interesting because it’s possible to turn it entirely off while enjoying a power-up time of only 30 µs when connected to the MCU’s GPIO. Comparatively, a memory like Flash is often kept in a deep low-power mode, partly because it would take ten times longer to boot up. Hence, thanks to our memory’s inherent speed, it’s possible to spend no current at all most of the time, use the MCU to wake it up quickly, write to it, and then power it back down. Something that’s not feasible with Flash. Interestingly, this aspect has already drawn ST partners to adopt our Page EEPROM in asset-tracking applications.

Many engineers may also have noticed that driving the Vcc line of the memory with one of the MCU’s GPIO pins is unusual. Indeed, this is impossible with a traditional flash module because their peak current consumption is too high. However, because ST’s Page EEPROM never requires more than 4 mA, it becomes possible to power it using the microcontroller’s pin, thus ensuring a simpler design and faster power-up time.

What to do to get started with Page EEPROM for asset tracking?

We developed an internal demo firmware showcasing an asset-tracking system. As the video above demonstrates, it uses a Bluetooth connector to send data wirelessly and implements features like data logging and over-the-air update capabilities. Developers thus get to see what’s possible on our platform. We are also sharing a firmware over-the-air implementation that can run on evaluation boards coupled with the X-NUCLEO-PGEEZ1 daughterboard, which houses a 32 MB Page EEPROM. Put simply, we want to help developers avoid a vital mistake: thinking memory is just a commodity, and it won’t have a tremendous impact on their application.

- Learn more about ST’s Page EEPROM

- Store your firmware and collect more data on battery-powered devices with the Page EEPROM – Webinar registration

- Why choose the Page EEPROM in Industrial Application? (Video)