The welcome light carpet is the car’s greeting to the driver on a cold, wet night – and it’s made possible by advanced LED and micro-lens array technology.

Car drivers live in the realm of the senses. The rich smell of leather seats, the growl of the engine, the thrust in the small of the back as the car accelerates – all these feelings viscerally connect the owner to their vehicle.

What we see when we look at a car also has a powerful effect. Car makers’ freedom to express the character of a car through its shape is constrained by safety legislation and the requirement for aerodynamic efficiency, so they are finding new optical signals of a car’s identity, such as headlight designs and indicator light patterns.

Now projected light is the latest optical effect to be used to brand a car’s interaction with the driver and passengers. Tiny assemblies of LEDs and micro-lenses embedded in the wing mirror, door sills and elsewhere project light patterns on to the road or pavement, producing effects such as the ‘welcome light carpet’ – the car’s optical ‘hello’ to the driver when the wireless key fob comes into range.

Projected lighting is a specialized optoelectronics technology pioneered by ams OSRAM – and now the company is developing the next generation of the technology: from static to semi-dynamic light projection, opening up new creative possibilities to car makers. The goal? To lift the driver’s heart when she or he sees the welcome lights shining on the pavement on a cold, wet night far from home.

Projected lighting systems: a complex assembly of precision components

Innovations in optical technology made by ams OSRAM underlie the appeal of projected lighting systems in new passenger vehicle designs. The technology succeeds in achieving two things concurrently:

– extreme miniaturization, so that the entire projection system can easily be accommodated in unused space, such as the underside of the wing mirrors or the door sills;

– and an attractive appearance – the sharp, well focused rendering of a pattern, symbol, or graphic artifact such as a logo.

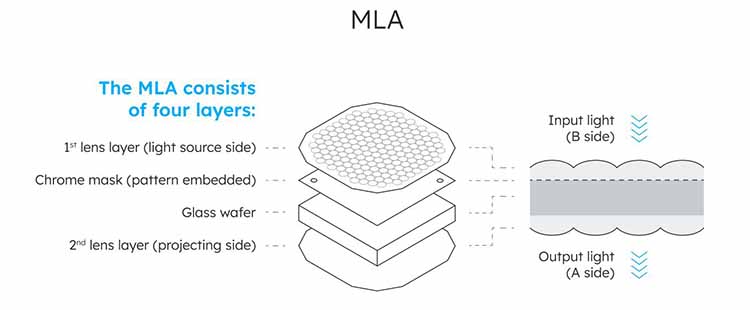

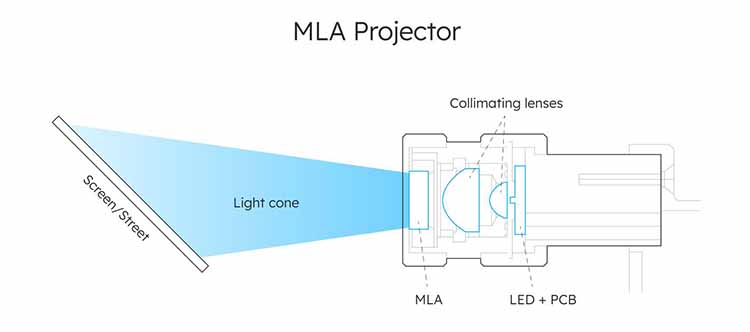

These tiny projected lighting systems consist of a lens assembly, known as a ‘micro-lens array’, shown below, through which light from an LED emitter is projected via a collimator to concentrate the LED’s light output on the lens assembly.

What is remarkable is that the individual lens features, each measured in fractions of a millimeter, can be sculpted individually so as to produce the pattern required in the application when light is projected through the array, forming an ellipse on the ‘image plane’ – the surface on which the graphic is displayed, such as a pavement or roadway.

Until now, the technology has only been capable of projecting static images on to the image plane. The latest innovation from ams OSRAM enables semi-dynamic projected lighting. Here, a segmented micro-lens array works in combination with four collimators split by an optical separator, with four independently steerable LED light sources.

Microscale lens fabrication

That this technology is available for use in high-volume consumer products such as cars is a tribute to the optoelectronics manufacturing technology and expertise of ams OSRAM. The micro-lens components are produced as wafer-level optics using technologies and equipment common to the semiconductor industry.

The precision and miniaturization possible when producing wafer-level optics is extraordinary: optic-to-optic alignment is of the scale of ±5µm, and optics-to-mechanics alignment is ±30µm. The extreme precision of this fabrication process ensures very high-fidelity reproduction of the specified lens shapes, to produce a sharp, focussed projected image.

Branding the car with light

Since the advent of high-power LEDs, car manufacturers have made attempts at branding and characterization of car lighting, for instance by animating indicator (turn) lights, and by creating unique outlines for daytime running lamps.

But in most cases the function – illumination – remains the same as it has always been. Projected lighting from ams OSRAM enables car manufacturers to create lighting systems for the car which communicate and engage as much as they illuminate. With the new semi-dynamic projected lighting technology, the car can now ‘talk’ to the user with light, both inside and outside the vehicle. For instance, when combined with other functions such as proximity sensing, the car can use projected lighting to acknowledge the presence of the driver – the car’s optical ‘hello’ when they approach the vehicle. Inside the cabin, projectors embedded in the roof lining or footwells can enhance the convenience and comfort enjoyed by the driver and passengers, but also provide an opportunity to create an optical ambience which belongs distinctively to the brand of car.

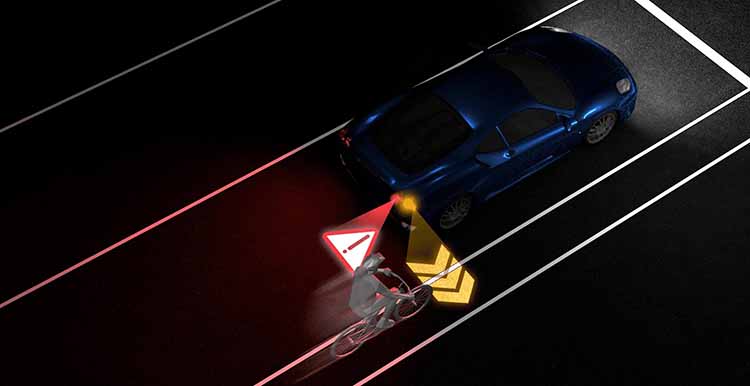

Implementing projected lighting technology in new car designs gives automotive manufacturers unprecedent potential to improve the safety, convenience, appearance, personality and functionality of the car’s lighting, as the pictured examples show.

Projected lighting also has important safety applications. Signals projected on to the road from wing mirrors, turn indicators or rear lamps can provide pedestrians, cyclists and other road users with a highly visible indication of the driver’s intentions.

A complete optical systems solution from ams OSRAM

Projected lighting technology combines wafer-level optics technology with advanced LED emitters – core areas of expertise of ams OSRAM. Working with customers in the automotive market and elsewhere, the company’s projected lighting specialists can optimize the combination of emitters and lens assembly to achieve high image quality, in a high value solution which can readily be integrated into a new vehicle design.

This application of optical technology is another example of the impact that ams OSRAM has on the world – imagining radical new applications that make life better for everyone. Discover more about our projection lighting applications and visit our virtual showroom to find out more in our demo video.

About The Author :

Sinisa Dohnal studied computer science at the University of Dortmund. He started his career in the automotive industry in 1996. In his career he has worked in several automotive fields, including vehicle lighting. Since 2018 he has been working at ams-OSRAM AG in Premstätten as Product Manager for the PLS (Projected Lighting Solutions) segment in the ISS division.