In harsh industrial environments, choosing the right connectors can certainly pose a few challenges for design engineers. Some factors that can negatively impact the proper functioning of these components include temperature cycling, shock and vibration, and other mechanical stresses. In addition to overcoming these challenging conditions, the connectors may need to withstand regular or routine mating cycles throughout their service life. Let’s examine these considerations in more detail, starting with the connector’s resilience to vibration.

Vibration goes with the territory for heavy motorized equipment. Although excessive vibration can be a sign of imbalance, misalignment or wear within the machine that will need fixing, there is an acceptable level that needs to be taken into account. Choosing connectors that are adequately resilient to this constant vibration is an important point to consider.

As well as vibration, wherever cables are subjected to mechanical stress – pulling, bending or frequent movement – effective strain relief is essential. Connectors with a surface-mount hold-down, for example, enable them to withstand a greater pulling force and adds to the overall footprint, which helps prevent the cable assembly from being ripped off the board.

When there are complex, repetitive movements involved, such as in robotic systems, backpotting may be necessary. Essentially, this is when the back of the cable connector is filled with epoxy resin to provide greater strain relief. Additionally, inadvertent or vibrational disconnection between cable-to-board mated pairs is prevented by latching or screw-locking between connectors.

As heat can be generated within equipment during operation or the surrounding environment can be extremely hot or cold, connectors may need to support a broad working temperature range. Depending on the particular temperature conditions that the end equipment is likely to operate, connectors specified with a range covering -55°C to +125°C should be enough.

Another important aspect to consider is the mating tolerance of the connector, especially when it is mated and unmated many times. This can happen when operatives need carry out firmware updates or re-configure the equipment. Any damage to the contacts during this activity, particularly in situations where the connector is blind-mated, can impact the proper functioning of the connector and may result in it needing early replacement. To avoid this from occurring, guiding features can be incorporated into connectors to help protect the contacts. An alternative option would be to consider selecting shrouded connectors, as they ensure the correct mating position. Polarization or keying can also be employed to aid mating accuracy.

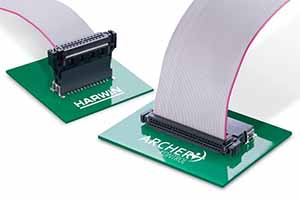

One such range of connectors that meets these industrial requirements and comes at an appealing price point is Harwin’s Archer Kontrol range. Durability with high performance and reliability are key characteristics of these products, which benefit from conventional products with several improved design features. The Archer Kontrol range of 1.27mm pitch surface mount connectors suits vertical, horizontal and cable-to-board mating applications. The products support between 12 and 80 contacts and are available in a variety of stacking heights. They have a contact current rating of up to 1.2A, and can deliver the 3Gbps data rates now mandated by industrial automation network infrastructure.

Unlike conventional connectors that may offer a working temperature range from -40°C to +105°C, Archer Kontrol connectors can withstand -55°C to 125°C with high vibration resilience. Thanks to a fully shrouded design – with built-in polarization – the contacts are protected against the possibility of damage during blind mating. Durability is also important in industrial applications and the Archer Kontrol connectors support 500 mating cycles. By considering each of the different elements discussed in this article, matching a connector to different industrial-oriented applications is much more straightforward. Taking a close look at Harwin’s Archer Kontrol series datasheet will provide all the necessary electrical and environmental performance specifications to make connector choice simpler.