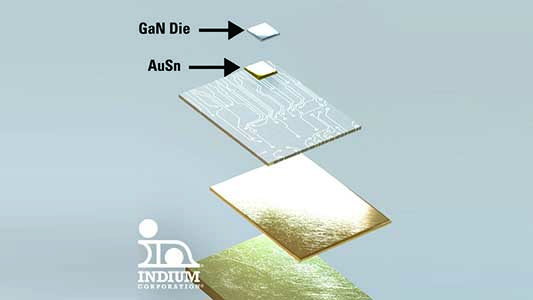

Indium Corporation® will feature its high-reliability, Au-based precision die-attach (PDA) preforms for critical laser and RF applications, as well as 5G communications, at the International Microwave Symposium, San Diego, Calif., June 11–16.

Indium Corporation is the leading solder supplier for laser and optical applications. Au-based alloys are a great choice to ensure the best performance and reliability possible for applications requiring a high-melting die-attach solder. In addition to meeting the demanding thermal and electrical requirements for high-reliability applications, they also provide the strongest corrosion- and oxidation-resistant solder joint possible.

Semiconductor laser die-attach applications require the highest quality, ultra-precise solder preforms to ensure accuracy and repeatability during assembly for a guaranteed highly reliable end product. Indium Corporation’s Au-based PDA preforms offer the highest level of quality available to deliver the best performance possible in critical, high-reliability die-attach applications. Features include:

- Highly accurate thickness control

- Precision edge quality, virtually burr-free

- Optimized cleanliness control

- Default waffle-pack method

Indium Corporation’s Au PDA preforms are available in the following alloys:

- 80Au20Sn, 79Au21Sn, 78Au22Sn, 75Au25Sn

- 88Au12Ge

- 82Au18In

- 96.8Au3.2Si

Indium Corporation’s AuLTRA™ 75 is an off-eutectic AuSn preform solution (75Au25Sn) designed to improve intermetallic reliability in applications using a die with a thicker gold plating, such as a GaN die used for high-frequency, high-power RF power amplifier devices for 5G and other critical military and aerospace wireless communications. AuLTRA™ 75 helps improve the operation of these critical technologies by adjusting the final solder joint composition, and improving wetting and voiding. The AuLTRA™ product line also comes in 78Au22Sn and 79Au21Sn compositions.

Indium Corporation’s AuLTRA™ ThInFORMS™ are 0.00035″ thick (0.00889mm or 8.89μm) 80Au20Sn preforms that improve the overall operational efficiency of high-output lasers. AuLTRA™ ThInFORMS™ help combat common issues such as:

- Shorting—reduced solder volume inhibits wicking up the die, minimizing the risk of shorting

- Poor thermal transfer—the ultra-thin 0.00035″ preform reduces bondline thickness (BLT), thus improving thermal transfer and increasing the longevity and performance of the device

A leading gold solder innovator, Indium Corporation’s gold-based portfolio includes wire, paste, preforms, spheres, shot, and ribbon manufactured with cutting-edge technology to ensure supreme quality and the utmost precision. The most commonly used gold-based alloy is 80Au20Sn: the pillar alloy of the microelectronics industry with a melting point of 280°C, 80Au20Sn works great in the majority of die-attach and lid sealing applications. It exhibits good thermal fatigue properties and is used in many applications that require high tensile strength and high corrosive resistance. Indium Corporation’s AuSn solder offers numerous benefits including:

- Highest tensile strength of any solder

- High melting point compatible with subsequent reflow processes

- Superior thermal conductivity

- Resistance to corrosion