AEC-Q200, Stress Test Qualification for Passive Electrical Devices has been expanded to include among other passive components, fuses.

The growth of electrification in automotive vehicles (Figure 1) has increased circuit protection requirements as fuses are necessary to provide overload protection. The new Automotive Electronics Council (AEC) Revision E removes the uncertainty of test requirements among manufacturers of fuses and ensures that AEC-Q200 Qualified fuses meet a high standard for ruggedness and reliability.

AEC Overview

Chrysler, Delco Electronics (General Motors), and Ford representatives met 1993 to discuss creating common qualification and quality system standards for electronic components. At the time, the automotive market was a smaller percentage of the total electronics market and received less attention from the manufacturers. The representatives formed the AEC and created two committees, the Quality Systems Committee and the Technical Committee.

The Quality Systems Committee is no longer active as quality specifications are now deferred to the International Automotive Task Force’s Standard IATF 16949, an automotive quality system standard based on ISO 9001. The Technical Committee creates the qualification standards for components, manufacturing processes, and test methodologies. The standards define the minimum set of tests that a component must pass to be qualified for use in automotive electronic applications. The initial work of the Technical Committee began on a standard for stress testing of integrated circuits to ensure device reliability in the automotive environment. This effort resulted in Standard AEC-Q100, Stress Test Qualification for Integrated Circuits. The AEC has since added AEC-Q101 for discrete semiconductors and AEC-Q200 for passive components. The AEC has expanded its membership to include automotive equipment suppliers and electronic component manufacturers.

AEC-Q200

AEC-Q200 Specification, Stress Test Qualification for Passive Components, hasdeveloped over the years and since June 2010 has been at Revision D. Components covered by the standard include various types of resistors and capacitors, inductors, transformers, resonators, crystals, resettable fuses (PTCs and NTCs), thermistors, and varistors. Depending upon the component type, qualified components must be capable of operating over a minimum temperature range from -40° C to +85° C; however, manufacturers can qualify their components to the specification’s specified temperature range.

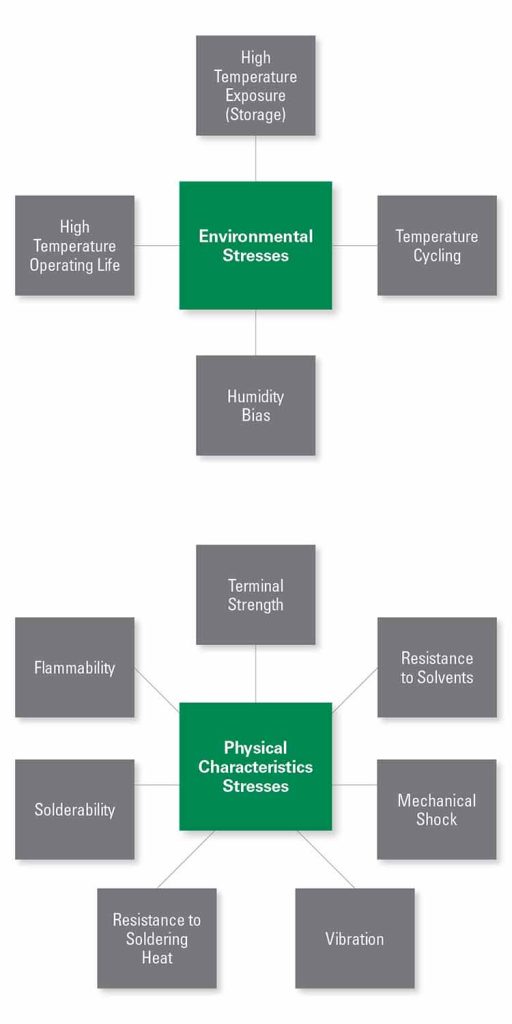

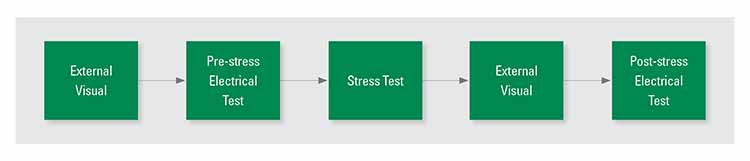

There are two main stress categories that components must pass: Environmental Stresses, such as temperature cycling and humidity bias, and Physical Characteristic Stresses, such as machinal shock and vibration. It is important to note that not all stresses apply to a particular technology. AEC-Q200 is divided into component technology tables that list out the stresses and may include additional requirements pertaining to that stress. Figure 3 visualizes the different stresses in each of the categories. The components must maintain their specifications under pre-test and post-test conditions, as shown in Figure 4.

Revision E of AEC-200

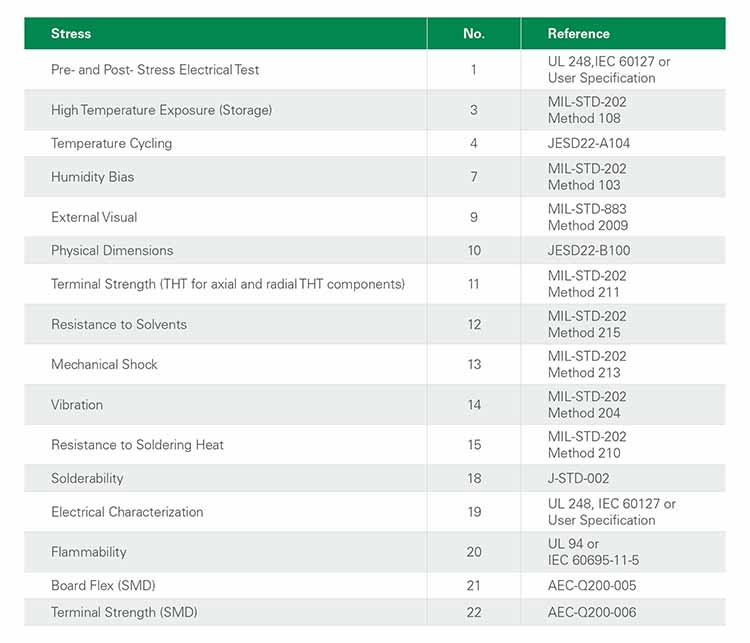

As well as many technical changes, clarifications, and editorial updates, the AEC has now published Revision E of the AEC-Q200 standard to include fuses. Fuses provide necessary overcurrent protection for all the circuits in a vehicle, and fuses should meet the rigorous standards for use in automotive equipment that other passive components similarly must meet. Littelfuse has contributed to the development of Revision E and the framework for defining the test requirements for fuses. The newly added Table 15 in AEC-Q200 lists the tests for fuses, the standard the test is based upon, and additional requirements needed to comply with the AEC-Q200 Revision E standard. The table below shows a compressed version of Table 15.

(Nano2® 885 Serie High Interrupting Rating 500VDC Surface Mount Fuses)

Enhanced reliability for automotive fuses ensured a coherent standard

AEC-Q200 Revision E now provides a single standard that manufacturers can use to design and test fuses for the automotive market. AEC Technical Committee members who are experts in fuse technology and testing have thoroughly reviewed Revision E. Design engineers developing systems for automotive vehicles will be able to select AEC-Q200 Qualified fuses that have been subjected to an extensive set of tests to ensure a rugged and reliable product. As a result, designers can be confident that their overcurrent protection components now meet the same uniform AEC-Q200 qualification methodology that other passive components meet. Therefore, designers can now select from a full complement of AEC-Q200-qualified passive components to develop reliable products for the automotive industry.

About The Author:

Saad Lambaz is the Global Standards Manager at Littelfuse Inc. He is a member of the AEC-Q200 subcommittee along with membership with UL, IEC, and other technical committees. He joined Littelfuse in 2014 after being involved in testing and certification services in his previous Underwriters Laboratories (UL) role. Saad’s current responsibilities include third-party component certification, standards development, and representation of Littelfuse in local and global technical committees. He received his BSEE from Southern Illinois University. Saad can be reached at SLambaz@Littelfuse.com.