Designers in the military/aerospace market must contend with some of the most stringent design constraints in engineering. Operational requirements have long forced mil/aero engineers to balance size and weight against power, making the choice of nearly every component in every system significant.

Tradeoffs among size, weight, and power (SWaP) are rarely simple calculations, even when making decisions about such basics as connectors and cabling – perhaps especially concerning connectors and cabling. Having options for nearly every part is important through the entire design process.

The weight of the matter

Weight borders on the irrelevant with most consumer items. A game console or an air fryer can weigh whatever it needs to weigh, and there are few, if any, consequences.

The needs of the military/aerospace market, in contrast, can be very impactful. More weight in applications such as these can mean reduced payload capacity, limited range, and decreased fuel efficiency. A common estimate is that every ounce of weight can amount to more than $1,000 in operating costs.

Weight is critical not only for aircraft, rockets, and other vehicles that fall in the mil/aero category, but also anything that will be cargo in any of those vehicles – in other words, nearly every product in the category.

The operational parameters of any product will have implications for power. Microwave ovens need to be capable of heating food in a reasonable amount of time, and the market has determined that requires a minimum of 600W.

The same applies to the mil/aero market. Any given mil/aero system might have to physically traverse a certain minimum radius, for example, or transmit an RF signal of some particular strength over some specific distance.

Operating parameters such as those will dictate an inventory of subsystems required to get the job done. That inventory will in turn suggest a general size and weight. All of the above will have ramifications for how much power the system needs.

Power supplies and the other elements of power subsystems tend to have relatively fixed weights and sizes for the amount of power they are to provide a system. So when mil/aero designers need to balance power requirements against size and weight, they usually start by determining which elements other than power components can be slimmed down.

Making space

Size tends to be related to weight, but saving space has its own separate ramifications. The mil/aero market’s transition from building networks with copper wire to optoelectronic networking provides a case in point.

Though we want to talk about space, the subject of weight is unavoidable. For starters, copper wire is heavier than optical fiber: optical fiber weighs roughly four pounds per 1,000 feet, while the same length of copper weighs nearly 10 times as much.

It is also just as important that optical fiber is significantly smaller in diameter than copper. Commonly used Cat 5e cable takes over 100 times more space than the necessary amount of fiber optic ribbon for the same application. Swapping out copper for fiber gives designers the option to either create a more compact system, or to devote the saved space to another purpose. Utilizing fiber also affords an extraordinary increase in bandwidth as an added benefit.

Optoelectronic technology is common in military aviation for all these reasons and is now being increasingly adopted in the commercial sector.

Connectors add up

Whether a designer chooses to stick with copper wire or upgrade to fiber, some of the most significant SWaP choices will involve the selection of connectors that are lighter, smaller, or both.

There are three ways to save space, weight, or both with connectors. One, pursuant to the discussion above, is to use fiber instead of copper.

Engineers could otherwise elect to use rectangular connectors instead of circular ones, or to use connectors made of lighter composite materials, rather than commonly used aluminum or steel. That’s not an either/or proposition – as we shall see, rectangular connectors can incorporate composite materials.

Shape matters

Circular connectors were once the norm, but rectangular connectors now dominate in several markets, including factory automation, robotics, and power generation equipment. They are now making headway in the mil/aero sector.

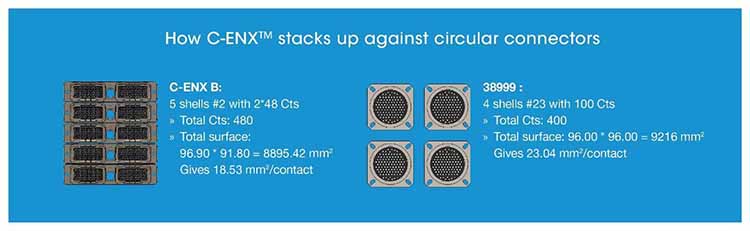

Although any circular connector isn’t that much larger than its rectangular counterpart, they do tend to be larger and require more space around them for fastening than rectangular connectors. Rectangular connectors can be stacked closer together and be affixed with external hardware to ensure stability in harsh environments. Rectangular connectors can also be ganged together to combine shells for additional space savings.

Composites are lightweight

Another means of saving weight is the use of composite shells. These shells are polymer structures with ceramic filler. They are much lighter than even aluminum shells (themselves a lightweight alternative to stainless steel). This choice can cut weight by as much as 40 percent.

Composites do not start out with the same performance characteristics as metal, but adding nickel plating provides effective shielding for composite connectors. With the plating, the performance between the two types is more comparable, so composites increasingly merit evaluation in mil/aero applications. As a bonus, composites also tend to be less expensive than aluminum, largely because the production process is easier.

Connectors for optoelectronics

Earlier we discussed how copper wire is far heavier and takes up much more space than optical fiber, but it is also noteworthy that the connectors for optoelectronics are also more lightweight and take up much less space.

That optoelectronic connectors are smaller and lighter is a logical consequence of how much smaller fiber is than wire.Circuit designs may be as simple as a few fibers or as complex as hundreds of fiber nets. Circuit sizes can run from a routed ribbon fiber only a few millimeters wide to a large, complex 400-square-inch flat circuit.

These are only a few of the many options for optoelectronic connectors, just as there are many different kinds of connectors and shells for copper wire networking.

Summary

Every cubic millimeter, every ounce, and every microwatt matters in mil/aero designs, making the selection of nearly every component in everything from wiring systems to power supplies to instruments subject to a SWaP analysis. Note that many contractors and manufacturers use the term SWaP-C (or a variation on that, such as SWaPC2). The C can stand for cooling and/or cost. In design, power and heat are commonly understood to be intertwined, but adding the C can be a reminder that extra attention to cooling might be necessary in mil/aero systems almost certain to be used in harsh environments. Meanwhile, though one should expect that designers are keenly aware that cost is always a consideration, some believe in making it explicit.

About The Author :

Scott Miller | Director of Product Management | Cinch Connectivity Solutions

For more than 25 years, Scott Miller has worked in the electronic components industry working with interconnect manufacturers, tackling the toughest markets out there: Aerospace, Defense, and Heavy Industrial.

Most of Scott Miller’s experience is in Product Management, which became his preferred profession after receiving his MBA from University of Phoenix, and learning how Product Management is thoroughly involved in just about all aspects of a vertically integrated interconnect manufacturer. Product Management is about taking the lead as it pertains to new product development, working with customers to find the right solution for their current project, establishing and executing the Go To Market strategy, product/technology road mapping, being the business office for the products him and his team support, as well as supporting all relevant functional groups within the organization to deliver the best performance of the goals and objectives set by all stakeholders, including customers, leadership, and ownership. As experience has been gained, mentoring and helping team members grow professionally has been a welcome and fun addition to Scott Miller’s responsibilities.