Plymouth, WI — Kurtz Ersa Inc., a leading supplier of electronics production equipment, is pleased to announce plans to showcase its latest advancements and a range of cutting-edge soldering machines at the 2024 IPC APEX EXPO. The event is scheduled to take place April 9-11, 2024 at the Anaheim Convention Center in California. Attendees can visit Kurtz Ersa at Booth #2320, with additional machinery available for viewing in Booth 2620.

This year, Kurtz Ersa will debut several new products, making their first appearances in the Americas:

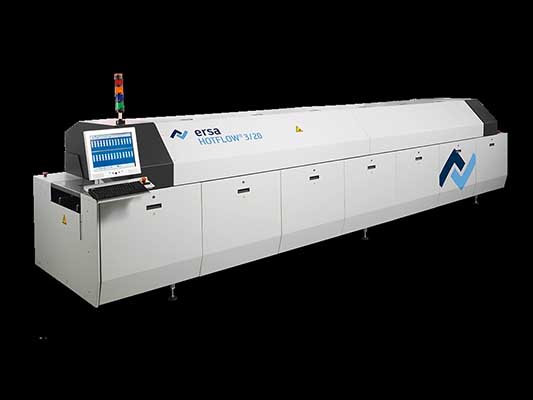

1. HOTFLOW THREE – Ersa Reflow Soldering Machine The Ersa HOTFLOW THREE, manufactured in Mexico starting in 2024, utilizes patented Ersa heating technology for optimal heat transfer with minimal energy and nitrogen consumption. Setting the industry standard for productivity to footprint ratio, this reflow soldering system offers double to quadruple transport options, enabling remarkable throughput increases without additional floor space. With up to four transport speeds and precisely adjusted transport widths, a wide variety of assemblies can be efficiently processed.

2. VERSAFIT 500 – Press-Fit Technology The Ersa VERSAFIT 500 is a highly flexible inline system designed to significantly enhance the competitiveness of press-fit technology in electronics production. This alternative connection technology reduces production costs and improves assembly quality. At its core is the servo-electric press cylinder, offering precise control and monitoring of force and travel.

3. VERSAFLOW ONE X-Series – Enhanced Selective Soldering Building on the success of the VERSAFLOW ONE, the X-Series introduces variability, optimizing throughput, economic efficiency, and soldering quality. This compact in-line selective soldering system features a dual-pot soldering module, providing exceptional flexibility and performance.

4. ERSA MK2 Soldering Stations The new ERSA MK2 line of soldering stations boasts the patented Tip’n’Turn concept for quick and secure tip exchanges, coupled with a remarkable performance increase of 20%. These stations, starting at 150 Watts, ensure optimum performance for manual applications. With advanced soldering tip technology, precise temperature control, and rapid heating and reheating capabilities, the MK2 series sets new standards for soldering stations.

In addition to these groundbreaking products, Kurtz Ersa will present its comprehensive range of equipment, including selective soldering, reflow soldering, wave soldering, stencil printers, rework systems, optical inspection devices, hand tools, and additive manufacturing solutions.

Visit Kurtz Ersa at Booth #2320 to explore the latest soldering technology advancements. For more information about Kurtz Ersa Inc., visit www.ersa.com.