The latest and most advanced technology is always believed to be superior. Sometimes, however, it is better to use tried and tested, decades-old, current, or even legacy technologies. There are, of course several other challenges associated with older equipment, including efficiency, inconsistent quality, expensive maintenance, and manual labor.

Replacing older manufacturing equipment involves a different set of considerations for business owners. It is not uncommon for legacy equipment to represent capital investments of millions of dollars and years of planning. Consequently, the retrofitting approach is more cost-effective.

Production environments can be greatly improved by introducing intelligent automation. Existing systems can create additional value through increased automation. Because older machines are often already written off, the economic impact of higher productivity, without the need for major new investment, is particularly advantageous for survival in an international market. Automated machines must accurately record and analyze operating data for modernization to succeed. Furthermore, it is essential that any conclusions drawn from these evaluations can extended to other manufacturing sites.

The difficulty with legacy machines is that we lack the knowledge to ask the right questions. How can this be resolved? Retrofitting machines is the best strategy.

Retrofitting is the process of updating or adding new features to existing equipment using an IoT solution in a non-invasive way. As a result of transforming a machine into its digital twin, production can be examined and optimized in greater detail and better efficacy.

Proof of concept in partnership

Würth Elektronik is an avid supporter of the open-source concept and together with FEGA & Schmitt and IAV has realized this proof of concept for industrial cutter monitoring.

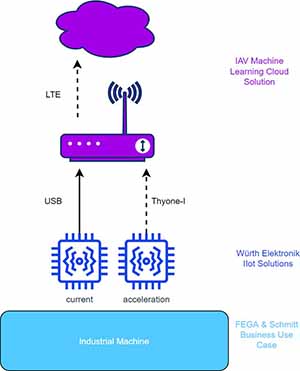

FEGA & Schmitt conceptualized this project, Würth Elektronik supplied connectivity and sensing components and, together with IAV, provided cloud infrastructure solutions . IAV also offered data analysis and full system integration services.

The goal was to develop an easy-to-install product for FEGA customers, to monitor industrial cutting machines and detect utilization based on current measurements, as well as to detect possible problems with the cutting tools before they occur.

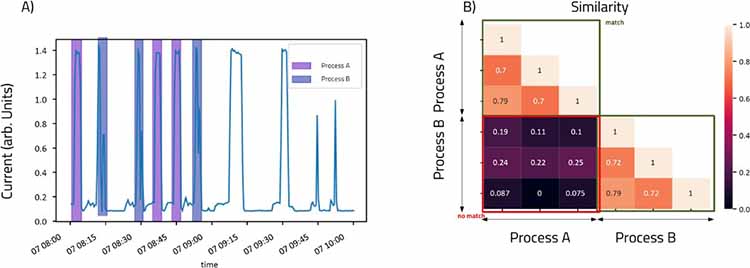

Sometimes, a particular combination of tool movements can cause tools to break. By identifying this set of movements, a failure prediction can be made. Consequently, there will be significantly less production downtime. A current measurement, on the other hand, provides the ability to determine machine utilization and simplifies the planning process.

During the Proof of concept, a strict requirement for the installation was not to interfere with the customer’s infrastructure nor to cause any process downtime.

Customers receive comprehensive system availability information from the finished product. Predictive maintenance is a key characteristic and differentiator for FEGA & Schmitt products through the use of sensors and AI-supported data evaluation.

Prototyping with FeatherWing boards

FeatherWings are a set of stackable prototyping boards with different functionality. Würth Elektronik created a range of FeatherWing development boards that are open source and fully compatible with the Feather form factor. This includes sensor wings, WE Pro-Ware wireless connectivity, Wi-Fi, and various power supplies. There is a GitHub repository [1] for all open-source boards, including their schematics, BoMs, software and cloud connectivity descriptions for Azure and AWS.

Sensing by acceleration

Sensor FeatherWings are used to create the initial data points. As the acceleration is closely connected to the movement of the cutter hand, the use of an acceleration sensor is a good starting point for monitoring movements.

The WE Sensor FeatherWing is a development board with four sensors. In addition to the Adafruit Feather form-factor, it is also compatible with Sparkfun’s QWIIC-connect, which provides a standard I2C interface that is also compatible with STEMMA QT and Grove/Gravity. This offers endless possibilities for prototyping.

All the above makes it easy to plug-and-play various sensors and devices from different manufacturers without a lot of wiring and makes it extremely useful for prototyping.

Connectivity by LTE-M/NB-IoT

Node and gateway connectivity is resolved in different ways. Gateway/cloud connectivity can be established in two distinct methods. Using an industrial Raspberry Pi with LTE connectivity, vast amounts of data is sent to the cloud for spectral analysis throughout the model generation phase. After the model is created, connectivity is switched to Würth Elektronik’s Adrastea-I LTE-M/NB-IoT module. This greatly reduces network traffic and, consequently, costs. Both methods have been tested in cloud-connected production environments.

The node is connected to the cloud via a gateway using the Thyone-I Wireless 2.4GHz proprietary radio module. Security should not be underestimated, therefore the gateway to cloud connectivity uses the TLS protocol, and the node employs a similar approach with the secure element (ATECC608A-TNGTLS from Microchip Technologies) on one side and the cloud key vault on the other. The whole connection is protected and encrypted between all the communication participants, nodes, gateways, and the cloud.

Implementation in detail

Vibration measurement

To select the appropriate accelerometer, a clear understanding of the application and its measurement tasks is essential. In this case, a 3-axis acceleration MEMS sensor was used to detect cutter arm movements. Developers have long hoped to take advantage of the MEMS sensors offer in terms of size, cost, and reliability, and this was fully exploited using a WSEN-ITDS – 3-axis acceleration sensor.

Current measurement

Current measurements must be non-invasive since the devices being monitored cannot be interfered with. The solution should be easy applicable to any similar machine. For this purpose, the WAGO split-core current transformer 855-4101/400-001 and the SparkFun ACS723 Hall-effect sensor breakout were used. The advantage of using a Hall-effect sensor is that the circuit being sensed and the circuit reading the sensor are electrically isolated; hence, the circuit being senses can operate at higher DC or AC voltages than the main board.

Connectivity solutions

For proof of concept, two versions of the connectivity solutions were used. Version one of the connectivity, used in the initial data collecting stage, was an Industrial IoT Raspberry Pi compatible gateway. A Linux-based system was used to generate C-code and optimize the data collection and transfer, as a vast amount of data is necessary to validate machine behavior. For the cloud, a dashboard was created for real-time monitoring of the data using Node-Red and Grafana. In addition, the time stream data was analyzed to identify trends and patterns with machine learning. Similar process patterns are automatically recognized and labeled. The remaining patterns are marked as unknown. This data serves as the basis for process statistics that can be used for various business use cases, such as process monitoring, quality assurance and predictive maintenance.

Testing in a real-world environment

Many challenges were encountered during the real-life testing: loss of data as a result of the distance and various radio sources in the manufacturing hall, constant movement of the stackable boards and power supply, or lack thereof.

Acceleration sensors were mounted on the cutter arm without any nearby power sources. This obstacle was overcome with the help of a LiPo battery. Despite the low standby current consumption, constant data transmission during the initial stage drained the battery. Vast amounts of information were transmitted daily, resulting in an empty battery every two to three days. The solution was to use a solar panel to charge the battery. For that purpose, an open-source solution from Adafruit was used.

The second problem was the location of the sensors and radio modules. The sensor has to be situated on the tool handle, which is a moving part. On the machine, all moving parts are protected by metal housings, which act as a Faraday cage. Despite being small and efficient, the integrated antenna was of no use. This was resolved by attaching an external antenna to the outside of the housing.

The current sensing part is a composition of split-core current transformers and Hall-effect sensors for each phase. Combining two sensors required calibration which was performed by Würth Elektronik.

Speeding up prototyping

Making a proof of concept with open-source components can dramatically reduce prototyping time. Combining pre-existing boards with standard pinning and sensors with standard connectors makes it easy to test and experiment with the setup.

Using two stages in the proof-of-concept prototyping allowed for the creation of an effective model in the first stage, which could then be implemented in the second. The second stage will deploy local models on the microcontroller and only send out the bare minimum amount of data. The necessary data will be sent to the cloud using the Adrastea-I cellular module.

Würth Elektronik offers free Arduino style SDKs for different processors and sells the boards. These boards can be easily adapted using data (PCB and BoM) from Würth Elektronik or Adafruit’s Awesome Feather GitHub [2].

This use-case demonstrated that using open-source standards for prototyping offers flexibility, resulting in enormous implementation speeds.

About the Authors

Adithya Madanahalli graduated from the Technical University Munich with an MSc. in Communication’s Engineering. He then worked for several years as a software engineer in the field of wireless connectivity and sensors. Since 2022, Adithya has been an IoT Engineer at Würth Elektronik eiSos in the business unit for Wireless Connectivity and Sensors. There he specializes in the design and development of IoT solutions focusing on hardware, embedded software, and end-to-end security.

Dr. Jan Gieseler received a Dipl.-Phys. from the University of Karlsruhe, Germany and an MPhys. in Optoelectronics and Lasers from Heriot Watt University, Scotland, followed by a PhD. in Photonics from ICFO in Barcelona, Spain. After that, he continued to work as a postdoctoral scientist in fundamental research at ETH Zurich, Harvard University and ICFO. In 2020, Jan joined the DigitalLab at IAV in Berlin, Germany. There, he works as a Data Scientist with primary focus on data engineering, time series analysis and IIoT & smart sensor solutions.

Bernd Grimm is a business economics and information technology graduate. Since starting his job in the electrical wholesale industry in 2008, he and his teams worked on numerous projects with a strong focus on customer service. He has been the industry and facility leader for project management at Fega & Schmitt since 2019. In this capacity, he collaborates with his team on the project “Be.Linked,” which aims to establish the topic of “service distribution paired with digitalization & AI” for Fega & Schmitt.

Miroslav Adamov studied physics and informatics at the University of Belgrade, Serbia. After that, he continued scientific work at TU-Berlin, WIAS Berlin, FAU Erlangen/Nürnberg and Center of private equity research in Munich. After a couple of years in quantitative finance, 2015, he joined Würth Elektronik as Senior Business Analyst. In 2017 he took over the position of Senior IoT Solution Architect with primary focus on conceptualization and implementation of Industrial IoT solutions.

Eduard Richter completed his education as a certified electrical technician and Bachelor of Business Administration. Since 2017, he has been working in electrical wholesale as a technical key account manager. His task is to position FEGA & Schmitt services with existing and new customers. With his sales expertise, he is involved in the development and improvement of the services.