All industry verticals including manufacturing are adopting transformative measures to mitigate climate change which has intensified in the last decade. Decarbonising the process systems so that there are lesser Greenhouse (GHG) emissions thus achieving Energy transition is one of the top goals for every Country. The best and quickest way to do that is reduction in energy consumption itself. There has been reduction in GHG emissions but there is scope for improvement. The adoption of AI and Digital Transformations has been relatively slow in the industrial sectors. But with increased Sustainability demands manufacturing companies are looking at every opportunity to improve their energy efficiency and reduce the carbon footprints. AI/IoT Solutions can play a major role in bringing down energy consumption in factories as well as Real Estate/ Properties employing HVAC systems for cooling, heating & ventilation.

Technology companies providing end to end solution right from data capture to process control are in focus. The advantage is the reduction in complexity of integration different technologies from different companies and costs. Hence companies having IoT platform, Communication networks, Enterprise software, distributed computing and Artificial intelligence technologies are set to see tremendous growth in demand in near future. In the latter part of last few decades, process automation and auto control systems have found great usage. These are rule based automation systems designed to help factories better control of the manufacturing process. Strangely, the adoption of AI and Digital Transformations has been relatively slow in the manufacturing industries. But with increased competition and dwindling profit margins, manufacturing companies are looking at every opportunity to improve their energy efficiency and become cost competitive, at the same time, meet their sustainability goals.

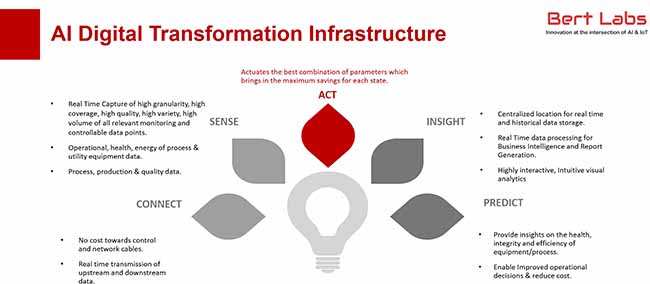

It is critical for Industries to build their digital transformation infrastructure and adopt AI/IoT platforms into their routine practise. It brings about seamless uninterrupted automated execution bringing about not only energy optimization but overall efficiency improvement including reduction in raw material consumption and consumables, thereby impacting sustainability. Digital Transformation infrastructure should (a) sense i.e. Real Time Capture of high granularity, high coverage, high quality, high variety, high volume of all relevant monitoring and controllable data points, Operational, health, energy of process & utility equipment data and Process, production & quality data. (b) Connect i.e. real time transmission of upstream and downstream data with no cost towards control and network cables and (c) Act i.e. Centralized location for real time and historical data storage, real time data processing for Business Intelligence and Report Generation & Highly interactive, Intuitive visual analytics. The level of Digital Transformation infrastructure will depend on the current digital state of the plant. The beauty of Centralized data repository is that it can store all the data that is generated from process and can provide integrated Energy/Material dashboards and reports customized to the end stakeholder like a Plant Head, CXO’s, CEO, Production Head.

The AI models deployed on the process learns continuously from the real time data and improves its performance over the years. Thus, the factory continues to benefit and can see reduction in energy consumption, achieve sustainability goals. Thus, it the right time now for all factories to invest in AI technologies which can provide both the Digital Infrastructure and the AI powered controls that can make a huge impact in the way the factory operates and brings in all round benefits and huge impact on Sustainability.