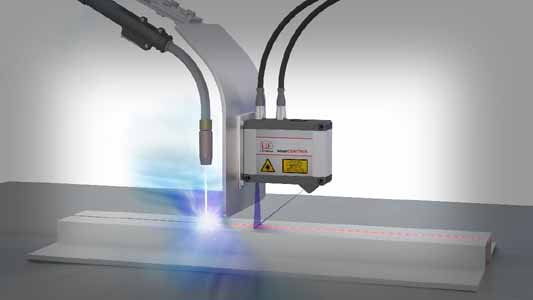

Automated processes in the metal industry ensure consistently high product quality and process reliability. In laser welding and laser cutting, the high degree of automation requires extremely precise tool guidance. Laser scanners from Micro-Epsilon are used in order to meet the high requirements in automation processes. They intervene even before the cutting and welding work and create precise 2D/3D profiles. Based on this measurement data, exact tool guidance is possible.

Speed, flexibility and consistently high product quality are required for automated welding and cutting operations in the metal industry. Depending on the manufacturer, the processes can be very individual and complex. Laser scanners from Micro-Epsilon are used to achieve high efficiency. An exact profile of the object to be edited is created before the tool is applied.

Similarly, scanCONTROL can be very useful in 3D scan of components before laser cladding, 3D measurement of components prior to plasma cutting, Optimizing weld seams with profile measurements, completely automatic 3D repair welding, etc.

Blue Laser Technology

In addition to the red standard laser, Blue Laser Technology is available for measurements on demanding surfaces. Micro-Epsilon holds a patent for measurements with blue lasers on red-hot glowing objects exceeding 700 °C and (semi-)transparent objects.

Micro-Epsilon India Private Limited

Office No. 101 A | Delta 1 Giga Space IT Park

Viman Nagar – 411014, Pune | Maharashtra

Tel.: +91 20 4913 1030 | Fax: +91 20 4913 1001