Abstract

Software-configurable systems enable industrial original equipment manufacturers (OEMs) to deliver unprecedented flexibility to the factory floor while simplifying product complexity. Introducing the Arduino OPTA platform for rapid development and deployment of automation systems, this article examines the features offered by Analog Devices technology integrated into the module, as well as complimentary ADI solutions for complete signal chains in input/output (IO) modules.

Introduction

New software-configurable input/output (SWIO) features for control automation equipment allow any industrial IO function to be accessed from any pin, with the ability to configure channels anytime. This allows for customization at the time of installa- tion—resulting in faster time to market, fewer design resources, and universal products that can be implemented broadly across various projects and customers.

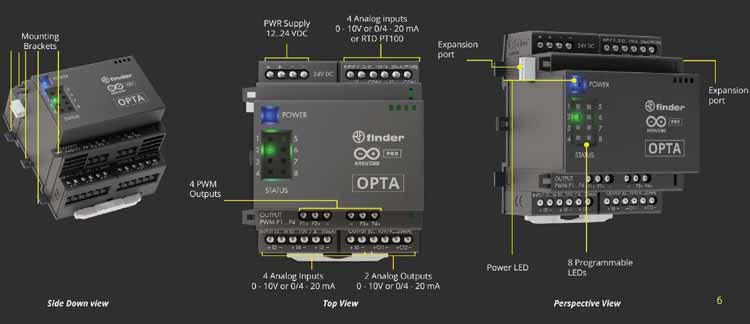

To minimize the size of programmable logic controllers (PLCs) and enhance their configurability, Arduino has integrated the AD74412R into their micro PLC platform. The Arduino OPTA, shown in Figure 1, serves as an ideal platform for this quad-chan- nel SWIO solution. It allows system architects and end users in building and process control environments to program it with ease using the Arduino PLC-integrated development environ- ment (IDE). The SWIO single-chip solution combines functions for analog output, analog input, digital input, and resistance temperature detector (RTD) measurements, with serial port interface (SPI)-compatible data transfer and programming.

Arduino Module Detailed Information

Arduino designs, manufactures, and supports electronic devices and software, providing people globally with access to advanced technologies that interact with the physical world. Their products are straightforward, simple, and powerful, fulfilling the needs of users with ease. The PLC IO expansion exemplifies this, offering an easily configurable industrial instrument.

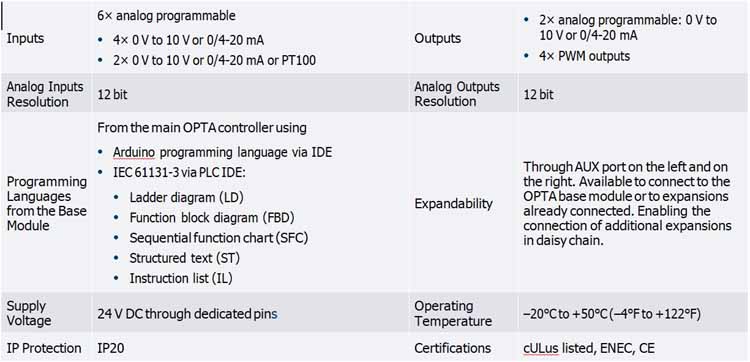

Table 1. OPTA Technical Specifications

The module’s hardware supports full software configurability, enabling end users to program the input and output connections directly from the cloud. The flexibility provided by the AD74412R within the IO expansion connected to the OPTA PLC offers a fully configurable solution for Industry 4.0 applications. The inter- face is user friendly, allowing connections to various devices such as valves, 2-wire RTDs, pressure sensors, position sensors, 4-20 mA devices, buttons, switches, etc., all programmable via software. This component supports the implementation of Industry 4.0 in safe environments, with its robust design ensur- ing protection and IEC 61131-3 compliance. Additionally, the expansion includes two ports specifically for 3-wire RTD preci- sion measurements.

The OPTA expansion enhances hardware capabilities while maintaining ease of programming through the Arduino IDE. The development tool offers a wide range of ready-to-use sketches, tutorials, and libraries, significantly reducing the time to market for the rail installer due to its low code approach and pre-mapped resources. Furthermore, the OPTA has the capability of real-time remote monitoring, firmware updates over-the-air through intui- tive Arduino Cloud dashboards, and secure communication with a broad array of connected devices. Table 1 lists the technical specifications of the OPTA unit, with key features illustrated in Figure 2.

Complementary ADI SolutionsComplete universal IO modules can be achieved by integrating the AD74412R with the digital output capabilities of the MAX14906, along with solutions for power, protection, processing, secu- rity, and communication. The push towards Industry 4.0 and the digitization of factories necessitates higher IO counts, which are supported by integrated power solutions such as the ADP1032. This IC not only provides two regulated outputs but also offers galvanic isolation, safeguarding analog front ends by isolating SPI and GPIO signals and integrating an isolated DC-to-DC con- verter. Similarly, compact printed circuit board (PCB) designs are facilitated by using the MAX17671, which regulates the 24 V input to a module, minimizing the need for external components.

In addition to Linux drivers for the AD74412R, ADI provides no-OS drivers, enabling the development of SWIO solutions for low power microcontroller units (MCUs) such as the MAX32650. Recent security concerns have heightened legislative focus on cybersecurity in manufacturing systems, prompted by the EU Cyber Resilience Act, which mandates cybersecurity require- ments for all “products with digital elements”. The MAX32650 features secure boot and key storage and can be paired with the MAXQ1065 cryptographic controller to provide a comprehensive root-of-trust and authentication solution.

Conclusion

SWIO using the AD74412R is ideal for remote IO modules, elimi- nating the need to deploy redundant fixed function IO channels in the space-constrained environment outside control cabinets. These modules are strategically placed within the control hier- archy to bridge traditional 4-20 mA IO to Ethernet-based com- munication. Edge-node Ethernet addressability facilitates the use of low level insights for cloud-based algorithms. T1L and advanced physical layer (APL) as implemented by the ADIN1110, a robust low power MAC-PHY, and the LTC9111 single-pair power over Ethernet (SPoE) power delivery (PD) controller offer an effi- cient, low overhead solution for this segment of the Ethernet ecosystem.

Reference

1“Cyber Resilience Act–Factsheet.” European Commission, December 2023.

About the Authors

Dr. Conal Watterson is a principal marketing engineer with the Factory and Process Automation End Market Team at Analog Devices in Limerick, Ireland. A Ph.D. and M.Eng. graduate of the University of Limerick since 2010, Conal has published a number of papers and articles on industrial fieldbus networks, diagnostics/reliability, and high speed signaling and isolation. His current focus topics are industrial automation controller and module signal chains and integration of new technologies for universal IO, new Ethernet topologies, intrinsic safety requirements, and secure processing to meet cyber resilience legislation.

Alessandro Leonardi is an account manager at Analog Devices, Milan. He studied electronics engineering and received a bachelor’s and master’s degree from Politecnico di Milano. After graduating, he was part of the field applications trainee program at ADI.

Giacomo Paterniani earned a biomedical engineering degree at University of Bologna. He completed his master’s degree in electron- ics engineering at University of Modena and Reggio Emilia. After graduating, he spent a year as a research fellow at University of Modena and Reggio Emilia. In April 2022, he joined Analog Devices’ graduate program as a graduate field applications engineer. In April 2023, he became an FAE.