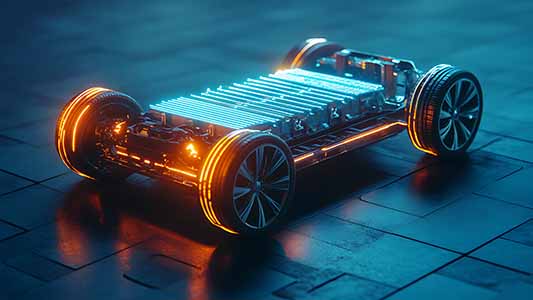

Use of electric vehicles is growing in India and the Asia-Pacific (APAC) region. Like adoption in other areas, the first wave of electrification growth strong in light mobility, such as two-wheel; three-wheel; and light, four-wheel commercial vehicles. To improve efficiency and operation, engineers should look for advanced inverter technology.

Light mobility platforms, like three-wheel vehicles, focus on two key voltage architectures: 48 V and 96 V. Key demands for light-mobility, electric platforms in India include a high range achieved through high efficiency and optimum performance in harsh conditions regarding thermal and ingress protection.

Without a separate motor controller and a dedicated vehicle control unit, these smaller machines have one inverter or controller. It must manage the motor and vehicle controls like the lights and HVAC system.

Sustainable electric solutions in India present challenges for engineers and designers of vehicles and equipment. This is especially true for vehicles operating in diverse environments with space constraints.

Two major manufacturers in India recently began electrification journeys. They required exceptional power control systems with minimal footprint and optimal performance for Indian road conditions.

Both manufacturers required inverters with exceptional characteristics: compact dimensions, low-voltage capabilities, and high power density. The systems needed to excel in applications operating in low-voltage architectures, a critical specification for their intended use cases. Through collaboration with the component manufacturer’s expert engineering team, these manufacturers successfully implemented solutions that addressed their requirements.

Three-Wheel Vehicles

In India, three-wheel vehicles are used for passengers and cargo, and they are also moving to electric power. Three-wheel electric vehicles (EVs) can improve health because of lower noise, vibration, and harshness.

The Challenge

A three-wheel EV manufacturer needed to find a 48-V motor controller to improve its vehicles’ efficiency and operation. The controllers needed to be efficient and have scalable power levels to excel in the many on- and off-highway applications in which the vehicles are used. In addition, the government mandate in India is to use equipment and components that are made in India, so the inverter needed to be manufactured in India.

The Solution

The manufacturer decided to use a motor controller that had been proven in field use for more than a decade. It incorporated in-demand features including multiple drivability modes that included:

- • A hill hold function

- • Traction control

- • Throttle response

Its optimized design provides reliability in challenging applications.

48-V Inerter

The 48-V inverter that will be manufactured in India

The Results

Because of the motor controller’s scalability, the manufacturer achieved a range of improvements because of precise testing and fine tuning of the motor control algorithms and limits. Additionally, the inverter provider manufactures the components in India, which was important for many reasons, including India’s mandate that equipment and components are made in India.

Improved Last-Mile Delivery

A leading commercial vehicle manufacturer in India needed to electrify its bestselling light commercial vehicle. This model has a significant market share across the subcontinent. This electrification initiative represented the company’s first venture into the electric vehicle market. This made the project strategically important and technically challenging.

Challenge

The initiative required best-in-class efficiency and range performance. The last-mile delivery truck also needed additional inputs and outputs to carry out bespoke vehicle control functions that manage the motor and specific aspects of the vehicle’s performance, handling, safety, or user experience.

The engineering team of the electric components manufacturer faced several constraints:

- • The power control system needed to operate efficiently at 48 V or 96 V.

- • The performance characteristics had to match or exceed conventional vehicle characteristics.

- • The system required a customizable software architecture to control the motor and customized vehicle functions.

- • Because of India’s varied climate zones and landscapes, the solution needed to withstand diverse environmental conditions.

Solution

The commercial vehicle manufacturer reviewed multiple inverter/controller options. The manufacturer’s team implemented an advanced inverter system that precisely addressed the last-mile delivery truck requirements. It showed traceability between end-user and original equipment manufacturer (OEM) benefits and the controller’s features. The inverter that the manufacturer selected had:

- • Industry-leading power density

- • Intelligent motor control algorithms that allow for accurate control and high-efficiency operation

- • User code features that empower and enable OEMs to develop and implement custom control features

These features allowed the customer to successfully integrate the motor controller, deliver best in class range performance though high efficiency performance of the motor controller, and implement all vehicle control and interfacing functions through the customizable user code feature

Results

The implementation of this specialized inverter provided sizeable benefits:

- • Successfully electrified the manufacturer’s bestselling commercial vehicle, maintaining the truck’s familiar form factor and utility

- • Achieved power density metrics that outperformed competing inverters

- • Enhanced operational reliability compared to alternative technologies

- • Maintained performance characteristics that matched or exceeded the standard vehicle

- • Reduced and simplified maintenance, reducing total cost of ownership

The results confirm how a manufacturer that configures its designs to the OEM’s specifications can deliver more relevant engineering solutions than those offering off-the-shelf products. The final implementation met and exceeded the manufacturer’s requirements, establishing a scheme for future electrification projects.

End users who operate these vehicles gain reduced operational costs, enhanced performance, and improved reliability—all while contributing to India’s sustainability objectives through reduced emissions.

Inverter-LV.png

A 48-V motor controller improved efficiency and operation.

Prad Walimbe is managing director, APAC, for Turntide Technologies. To learn more, visit turntide.com.