There is often a rush to connect everything to the cloud in today’s IoT world, whether it’s kitchen appliances, personal care products or everything in between. To address this need, low-cost, integrated 32-bit microcontroller RF modules provide a compact footprint solution for a low number of sensor inputs.

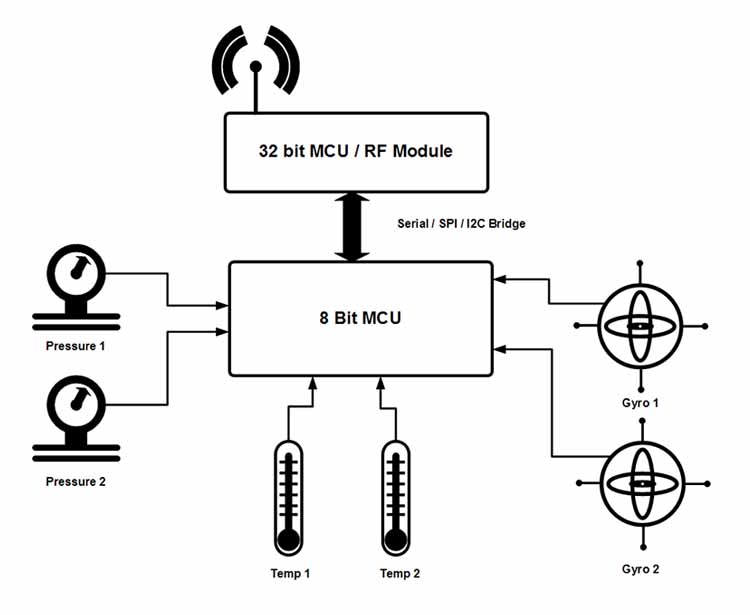

The communication stacks for Wi-Fi®, NB-IoT and Bluetooth® are well suited for the 32-bit domain. However, with the increasing number of sensor channels and the need for lower power consumption by remote locations, system design complexity is increased and higher computational power is needed to keep the RF channels secure. Additional 8-bit MCUs can then prove to be valuable (see figure 1).

True 5V IO Support and Sensor Aggregation

The 5V power supply ecosystem dominates the industrial environment. While there are 32-bit MCUs that are completely 5V capable, most integrated 32-bit MCU RF modules are 3.3V domain only devices. By allowing direct interface to 5V-based sensors, switch contacts and actuators via more GPIO efficient 8-bit MCUs in the 5V domain, this eliminates the need to add multiple level shifters or scale analog voltage inputs down to the 3.3V level.

This way, only the communication channel between the 8-bit MCU and the 32-bit MCU/RF module requires level shifting/scaling operation. When the 32-bit MCU module has 5V-tolerant inputs, serial resistor isolation is already sufficient since no level shifting is required at all. Even in cases where galvanic isolation is required, one can save costs by reducing the number of specialized ICs needed to protect the RF part of the system. Typically, remote installations require additional fault tolerance, resulting in multiple sensors or actuator controls to mitigate field failures. Redundant sensor interface connections pose challenges around input/output pins allocation on pin-limited 32-bit MCU/RF modules. Since 8-bit MCUs offer a higher interface pin density, this allows for the addition of intelligent fault tolerance to the sensor arrays at the front end. Machine learning algorithm is not required to determine if any of the three temperature sensors has failed. The decisions can be made locally with faster event response.

System Partitioning

With an outboard 8-bit MCU to interface with most sensors, it is possible to effortlessly snap a known working analog/digital front end onto different RF module back ends. Integrated 32-bit MCU/RF modules usually have a lot of example applications that demonstrate the ease of connecting to the cloud regardless of the vendors. The application examples are less likely to cover interfacing with sensors or actuators outside the standard I2C or SPI bus. With a validated sensor/control front end and a consistent and well-defined interface, there is greater freedom to choose suitable RF modules by minimizing the porting effort. The protocol layer between the two MCUs, which is supported by the new physical layer on the new RF module, completes the integration of the new system. Next, one can focus on the implementation of the new RF channel.

Loosely coupled systems with fault-tolerant hot-swap interfaces are a positive feature in industrial or remote environments. A complete system swap is sometimes unavoidable but minimizing the overall change to a known reliable system is the best option. This loose coupling also allows a trusted RF platform to support expanded system requirements without having to start from square one. Keep what you trust and improve what needs to be improved.

Intelligent Power Management

When one moves toward smaller IC gate technologies, there is always a trade-off between speed and static current leakage. The thickness of the gate oxide in the new process nodes is reaching a stage where it needs to be counted by the number of atoms instead of nanometers. In the world of 8-bit MCUs, larger process technologies provide better static leakage numbers. Though the best low-power management technique is to cut power altogether, adding an intelligent lower-power management device can also improve low-power operation. In some 8-bit MCU devices, active currents operate from a standard 32.768 kHz time crystal that leaks currents on 32-bit RF modules. Along with battery charging and battery health monitoring capabilities, this approach adds an accurate time-based power management system. In Wi-Fi-based units, active currents for 32-bit RF modules can touch hundreds of milliamps. Battery packs that are near death may not be able to sustain the start-up and transmission currents required to connect to a network.

The 8-bit MCU-based power management system can wake up the main RF module with a special wake-up command, which reduces the current demand to get the RF module online in a more phased sequence. A reduced TX power approach is sufficient to connect to the network. Peak start-up currents and voltage droops on regular cycles can be monitored by the 8-bit MCU power management system submitted with every wake-up cycle. This data can help cloud machine learning engines to improve profile battery systems and predict failures.

Programming Model/MCU Complexity

In the past few years, there has been considerable progress in improving the ease of programming 32-bit MCU/RF modules. While several of these modules offer Arduino-based support that speeds up development, it also becomes more complex when the project involves more customer sensors, power management or other peripheral interfaces. Though the Arduino support code is extensive, it is not complete and leaves scope for trust issues, especially in professional spaces. While IC vendors offer support, developers must still grapple with the additional complexity of integrated 32-bit RF modules at the bare metal layer. In addition, control registers based on 32-bits are often perceived as awkwardly large for a few bits of control or status. While this is true, it is difficult for one to pick out the wrong bit in the peripheral control value of 0x23AA123C.

The 8-bit MCU programming model shows a familiar interface in 8-bit chunks. It can sometimes stretch out to 16-bits for timer registers. The peripheral sets on 8-bit MCUs not only make it easier to debug bit fields, they also tend to be easier to understand as it does not consist of difficult complex power reduction or bus interface sync functionalities. Clock trees in 8-bit MCUs are much easier to understand. Even though they offer PLLs, the operation is quite basic. The biggest advantage of using an 8-bit MCU companion device is providing a low-power, low-cost, intelligent device that is capable of handling all the housekeeping, power management and tedious tasks.

Microchip’s PIC18-Q41 and AVR® DB families of 8-bit MCUs come with a large set of analog functions such as on-chip operation amplifiers and multi-level voltage GPIO. This reduces the need for additional external analog components and level shifters.

Although the availability of multi-core 32-bit MCU/RF modules is increasing, when it comes to designing robust low-power edge nodes in the IoT world, adding an 8-bit MCU can be a good option as they offer power and sensor management in small packages.