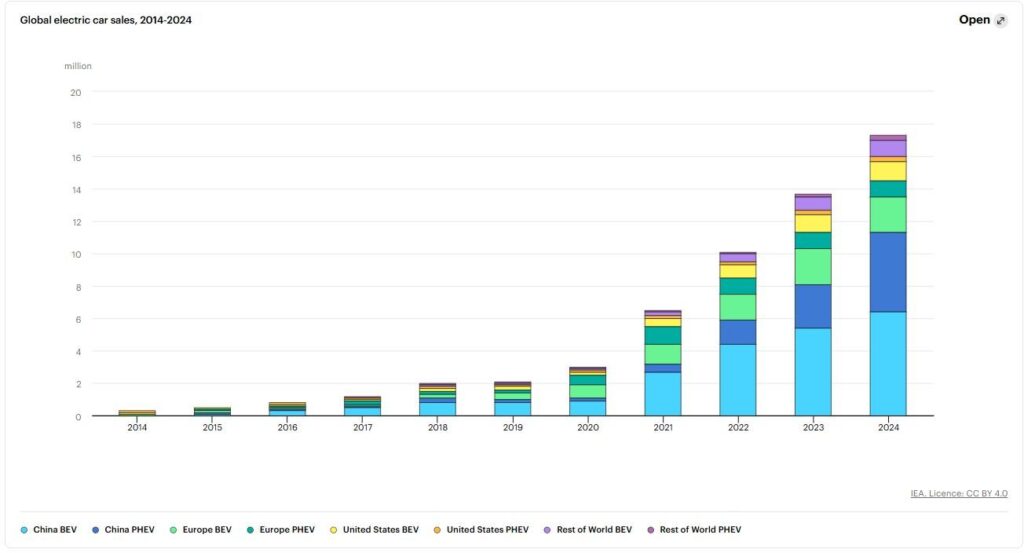

As electric vehicles (EVs) gain mainstream adoption worldwide, charging infrastructure has become the cornerstone of e-mobility expansion. Governments and automakers are accelerating their transition to electrification—global EV sales surpassed 14 million units in 2023, and the number is expected to exceed 20 million in 2025, according to the IEA.

(Source:IEA–Global EV Outlook 2025)

To meet growing demand for faster, more convenient charging, the industry is witnessing a rapid evolution in charging technologies:

- AC charging is transitioning from legacy 6.6 kW systems to more robust 11 kW and 22 kW three-phase solutions.

- DC fast charging, module power levels have increased from 20 kW to 40 kW or more, enabling higher system-level scalability.

- Ultra-fast DC chargers are now reaching 360 kW and beyond, significantly reducing charging times for next-generation EVs.

In parallel, new use cases such as fleet electrification, battery swapping, plug & charge protocols, and V2G (Vehicle-to-Grid) are pushing the boundaries of what charging stations must deliver—not only in terms of power, but also in interoperability, safety, and reliability.

These advancements, while promising, also bring significant technical challenges—such as grid stability, high power density, dynamic load management, and the need for

cost-effective testing solutions. To ensure reliable performance, manufacturers must conduct rigorous testing of charging stations under real-world conditions.

Key Testing Challenges in Ultra-Fast Charging:

- Grid Compatibility & Power Stability – As charging power increases, ensuring seamless integration with the power grid is crucial. Chargers must operate reliably under fluctuating voltage and frequency conditions.

- High Power Density Testing – The growing demand for compact, high-power charging modules requires testing solutions that can efficiently handle increasing power levels without excessive space and cost.

- Cost-Effective & Scalable Testing – Many traditional testing setups require multiple devices to achieve higher power levels, leading to increased costs and complexity.

- Space Optimization – Ultra-fast chargers require high-power test setups. Efficient space utilization in testing labs is essential, especially for 360 kW+ Supercharger testing.

In response to these growing technical challenges, ITECH offers comprehensive and high-precision EVSE testing solutions to help manufacturers ensure the stability and reliability of charging systems under real-world conditions.

1. AC Charging Station Testing: Higher Power Density, Greater Efficiency Power Trend: 6.6 kW (Before) → 11 kW (Now) → 22 kW (Future)

ITECH’s Advantage: IT7800/7900E/7900EP Grid Simulator (3U/21 kVA) provides

high-power density for AC charging station testing and simulates real-world grid conditions with precise voltage and frequency control. Compact design saves space while delivering high power output. With four-quadrant operation and regenerative functionality, power can be efficiently fed back to the grid—minimizing energy waste, lowering heat dissipation requirements, and aligning with green energy goals.

2. DC Charging Module Testing: More Power in a Single Device Power Trend: 20 kW (Before) → 40 kW (Latest)

ITECH’s Advantage: IT6600C Bidirectional DC Power Supply (3U/42 kW).

A single unit IT6600C meets the latest high-power DC charging module testing requirements and eliminates the need for multiple battery simulators, significantly reducing cost and complexity. Offers bidirectional power flow for precise energy testing.A 3U height single unit can output 21kW each in dual channels.

3. Supercharger Testing: Industry-Leading High-Power Testing in a Single Cabinet Power Trend: 250 kW (Before) → 360 kW (Latest)

ITECH’s Advantage: IT6600C bidirectional DC power supply for 360–400 kW

Supercharger Testing

It meets the full power requirement for ultra-fast chargers. Compact design saves space and reduces cost compared to traditional multi-cabinet setups. Meanwhile, it delivers high-precision testing for next-gen ultra-fast charging stations.To meet higher power demands, multiple IT6600C units with the same specifications can be paralleled, delivering up to 10 MW of output power with a fast, modular, and scalable configuration.

The future of EV charging is faster, smarter, and more powerful—and it starts with rigorous testing. With ITECH’s comprehensive EVSE testing solutions, manufacturers are equipped to overcome technical barriers, accelerate product development, and drive the next generation of clean, reliable charging infrastructure.

If you need more information, feel free to visit www.itechate.com