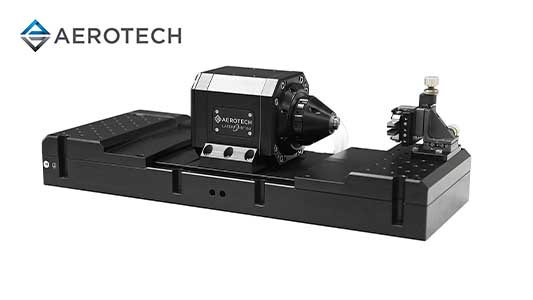

PITTSBURGH – Aerotech Inc., a global leader in precision motion control and automation, today introduced the LaserTurn®160, the ultimate cylindrical laser machining motion platform. Designed for unparalleled precision and efficiency, the LaserTurn160 delivers up to 40% higher throughput compared to similar systems, setting a new standard for medical device manufacturing.

Maximum Efficiency, Unmatched Precision

LaserTurn160 is optimized for high-dynamic performance, offering precise motion trajectories that ensure consistent, high-quality manufacturing outcomes. Its versatile capabilities cater to the unique requirements of medical device production, stent cutting, catheter fabrication, guidewire manufacturing and other applications.

Unrivaled Performance

The LaserTurn160’s direct-drive motors and crossed-roller bearings ensure ultra-smooth motion, enabling the production of highly reproducible parts. When paired with the powerful Automation1 motion controller, users can achieve the ideal balance of precision and speed for machining cardiovascular stents or other complex tubular components.

“The LaserTurn160 has established a new industry standard,” said Brian Fink, Product Manager at Aerotech. “With its ability to dramatically enhance throughput while maintaining excellent part quality, this platform is a game-changer in high-precision medical applications like stent cutting and hypotube manufacturing – when process throughput and part reproducibility are vital.”

Key Features and Benefits:

- Superior Throughput: Boosts process efficiency by up to 40% or more, reducing production times and increasing output with outstanding part quality and reproducibility.

- Dynamic Rotary Axes: Two direct-drive rotary stage options are available. ASR1300 delivers extreme high-dynamic performance for tube diameters up to 4 mm, with speeds up to 3000 rpm and accelerations up to 8000 rad/s². CCS130DR is capable of processing tube diameters up to 7.9 mm, blending high dynamics and versatility.

- Precision Workholding: Dead-length, pneumatically actuated collets virtually eliminate unwanted tube motion during gripping and regripping as the tube is fed through the rotary stage aperture.

- Enhanced Flexibility: Compatible with Type-D collets and an optional alignment gripper for seamless processing of tubes of varying lengths and diameters.

- Seamless Integration: Compatible with Type-D collets and an optional alignment gripper for convenient and precise material handling, plus front and rear tooling plates simplify integrating bushings and other process equipment. LaserTurn160 also supports wet- and dry-cutting configurations for maximum process versatility.