Waldenburg (Germany) – WRIS-RSKS Anti-Sulfur Resistors is the name under which Würth Elektronik presents its new family of more than 500 resistors whose outstanding feature is their resilience to sulfur. The range is aimed at manufacturers of durable electronics for applications susceptible to exposure from sulfur compounds. These are found in the transportation sector, mining, refineries, agriculture, the chemical industry, and metal processing.

Silver is used for the resistor contacts as it combines the highest electrical and thermal conductivity while preventing oxide formation. In conventional resistors, however, the silver of the inner electrode can react to form silver sulfide in sulfurous environments. This has a negative impact on conductivity and can even lead to component failure in some cases. Anti-sulfur resistors from Würth Elektronik have an additional layer of nickel-chromium alloy that protects the silver-based electrode from contact with sulfur gases.

The resistors’ sulfur resilience is designed for long-term reliability under harsh conditions and is tested in accordance with ASTM B-809. The operating temperature ranges from -55°C to +155°C. The SMT components come with resistance values from 1 Ω to 10 MΩ, temperature coefficients ±100, ±200 and -200~+400 ppm/°C, resistance tolerances of ±1% and ±5% and power ratings of 0.1 to 0.5 W.

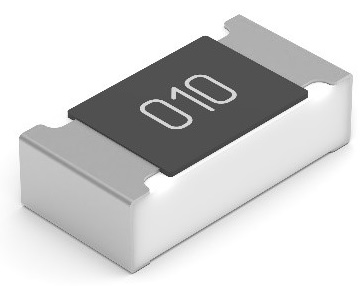

There are 247 variants of Würth Elektronik’s sulfur-resilient thick film resistors available from stock as standard items with no minimum order quantity. Another 260 can be produced to order. The packages 0402, 0603, 0805, 1206, and 1210 are offered.