At embedded world, congatec will be presenting first modules based on the preliminary COM-HPC Mini specification. And since modules alone are not enough to give OEMs the agility to optimize and expand their solution portfolio, congatec also offers a complete COM-HPC ecosystem, thereby helping developers of ultra-compact high-performance systems untie the Gordian knot of how to fit high performance onto a mini footprint.

Digital transformation is bringing technology, machines and people closer together than ever before. Collaborative robots, autonomous vehicles, AI-powered medical devices and faster 5G communications are just a few examples. To stay ahead in these accelerating markets, OEMs need to constantly review, optimize their solution offerings. A performance leap to COM-HPC is essential for many new applications in view of the rapidly increasing technical requirements: AI-based video analytics for situational awareness requires immensely high bandwidths with increasingly high camera resolutions. Voice control must be latency-free, which also requires AI to process ever higher resolution data streams. Graphics in combination with augmented reality is becoming increasingly demanding as well. Real-time parallel data processing in collaborative Industry 4.0 processes requires minimal latencies with increasing data throughput, too. Last but not least, cybersecurity also demands more computing power. And besides all this, system developers want to significantly optimize the connectivity of their platforms by leveraging latest technologies such as Thunderbolt 4.

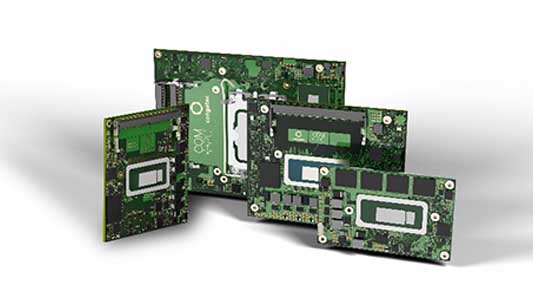

The COM-HPC standard was developed precisely to meet these increasing requirements. Now, the application spectrum is being widened even further as the availability of COM-HPC Mini modules with 13th generation Intel Core processors (codename Raptor Lake) will give developers access to a complete ecosystem for their third generation modular high-end embedded and edge computing designs. This ecosystem ranges from high-end Server-on-Modules to extremely compact Client-on-Modules that are barely larger than a credit card. With COM-HPC Mini, even the most compact COM Express Compact and COM Express Mini solutions will be able to benefit from a high-end performance boost and to leverage a significantly larger number of new high-speed interfaces. Thus, entire product families can migrate to the new PICMG standard – without requiring significant modification of the internal system design and housing despite the larger module and carrier board dimensions.

Making light work of design sprints from COM Express Compact to COM-HPC

This was not doable with the COM-HPC Size A specification. Measuring 95×120 mm (11.400 mm2), this to date smallest of the COM-HPC form factors is still almost 32% larger than COM Express Compact, which measures 95×95 mm (9.025 mm²). From a footprint standpoint, that’s 25 mm too wide to migrate existing COM Express designs to COM-HPC. Since COM Express Compact is the most widespread COM Express form factor and only the high-end currently still uses the larger COM Express Basic form factor, many developers faced considerable challenges – if only in terms of system design dimensions. But smaller is now possible. That’s why COM-HPC Mini with its 95×70 mm is a real liberator, opening up entirely new perspectives – in particular for the many ultra-compact system designs.

Admittedly, COM-HPC has only 400 pins, which is 40 pins less than COM Express Type 6 (440). Nevertheless, developers benefit from significant bandwidth gains and greater interface diversity thanks to newer and more powerful standards. This also puts the nominal reduction in the number of PCIe lanes from 24 with COM Express Type 6 to 16 lanes with COM-HPC Mini into perspective. Most ultra-compact system designs have rarely ever exhausted this interface package anyway. With PCIe up to Gen 5 and probably also PCIe Gen 6, 4x USB 4.0, 2x 10 Gbit/s Ethernet, which can be extended to 4 ports via 2x SERDES lanes, and up to 4 display interfaces, the COM-HPC Mini specification boasts everything that is state-of-the-art today. Besides additional modern peripheral interfaces, such as 2x MIPI-CSI for cameras, industrial classics such as CAN bus and 2x UART are also provided. A novel feature that has been added is functional safety support. This will make ultra-compact applications that must consolidate safety-critical real-time tasks alongside other tasks on one system achievable in the future. Examples of such applications include autonomous mobile robots and vehicles.

Newer works better in the long term

Many developers of new high-performance applications will also appreciate the added design security as the COM-HPC connector is specified for significantly higher data throughput rates than COM Express. It is true that the COM Express 3.1 specification, which was launched at the end of 2022 and supports PCIe 4.0 with up to 16 Gbit/s, also provides an upgrade path. However, the end of the line for further performance increases is already in sight. The recent launch of the 13th Intel Core processor generation showed that the gap is starting to widen as COM-HPC simply offers more. Some variants already support PCIe 5.0, which ultimately enables twice the data throughput. But there’s no need for developers to worry if they can live with the bandwidths offered by COM Express: The most popular Computer-on-Module standard will be around for many more years. It continues to be supported by the embedded vendors and receives careful upgrades within what is technically possible. This is especially good news for cost-sensitive and/or low-power designs, where COM-HPC is overspecified. However, those who want to leverage the latest technologies, such as Thunderbolt 4 connectivity, can now upgrade existing compact designs. Thunderbolt 4 ports implement power supply, bidirectional data transfer up to USB 3.2 Gen 2, as well as 4k video displays and 10 Gbit Ethernet via a single USB-C cable in maximum configurations. All this requires a bandwidth of up to 40 Gbit/s, which is simply not feasible with the COM Express connector, even in the 3.1 specification.

Ready for take off with 13th generation Intel Core processors

Numerous factors therefore speak in favor of the new COM-HPC standard. The launch of 13th generation Intel Core processors acts as an accelerator that will speed the introduction of such new system platforms. congatec expects a rapid and massive increase in series production of OEM designs based on these new modules, since the new processors with guaranteed long-term availability offer enormous improvements in many features while being fully hardware-compatible with their predecessors, which makes implementation very fast and easy. The modules based on the new COM‑HPC standard open up new horizons for developers in terms of data throughput, I/O bandwidth and performance density thanks to Thunderbolt and superior PCIe support up to Gen 5. The new COM Express 3.1 compliant modules, on the other hand, primarily secure investments in existing OEM designs with upgrade options for more data throughput thanks to PCIe Gen 4 support.

Compared to 12th generation Intel Core processors, the new COM-HPC and COM Express Computer-on-Modules with soldered Intel Core processors of the 13th generation deliver several advantages: They enable rugged designs for the industrial temperature range of -40°C to +85°C to utilize the innovative Intel hybrid architecture, which is an industry first. Next, they offer up to 8% more single-thread and up to 5% more multi-thread performance. Thanks to the improved manufacturing process, this performance increase goes hand in hand with higher energy efficiency. Other new features in this performance class (15-45 W base power) are support for DDR5 memory and PCIe Gen 5 connectivity on select CPU versions. Both contribute to even better multi-thread performance and higher data throughput. With up to 96 execution units (EUs) and ultra-fast encoding and decoding capabilities, the integrated Intel Iris Xe graphics architecture is ideal for high graphics requirements – for example, in applications that involve video streaming and/or video-based situational awareness. All these features lead to significant improvements in a wide range of embedded and edge computing applications, which increasingly implement artificial intelligence and machine learning functions as well as workload consolidation.

COM-HPC Mini is extremely robust

Now let’s envisage that these new Intel processors, along with rugged features such as soldered RAM and support for the extended temperature range, will be deployed on COM-HPC Mini modules. It is then clearly evident that these new modules will find universal use in high-performance system solutions that COM Express cannot address. There’s just one question: How complex is it to migrate systems from COM Express to COM-HPC? In a nutshell, it is only the carrier board that needs modifying, although the dimensions and interface design can remain unchanged. Certainly, the routing and components need adapting to accommodate the new performance, and it is not possible to simply replace the module. On the hardware side, however, it is ‘only’ a matter of adapting existing design practices to the new requirements of faster interfaces. High-speed signaling constitutes a particular challenge in this context.

Additional services and training to simplify the design-in

This is where manufacturers like congatec come to the aid of customers with a training academy that teaches carrier board developers about design-in best-practices. The training program aims to provide system architects with a quick and efficient introduction to the design rules of the new PICMG standard. The course guides developers through all mandatory and recommended Computer-on-Module design fundamentals and best practice schematics to enable them to start their own carrier board design projects. The knowledge transfer focuses on standards-compliant carrier board design, which is essential for building interoperable, scalable and durable custom embedded computing platforms. The congatec academy operates globally, offering online as well as on-site courses to developers at OEMs, VARs and system integrators.

While official design guides are a great resource, they are ultimately just a requirements specification. Developers also need to learn how best to put these fundamentals into practice. The congatec training program was designed with the goal of accelerating the knowledge transfer required to start such development projects in the real world.

The new congatec carrier board design training program, starting in April 2023, will give engineers an introduction to the world of high-end embedded and edge computing – from PCB layout principles to power management rules, signal integrity requirements, and component selection.

Customers who want to use COM-HPC but do not have the resources to integrate the modules themselves, can rely on congatec’s design-in services to handle this. Carrier board designs, optimized cooling solutions, and extensive system integration services are also offered. With this comprehensive range of products and services, congatec continues to build on its mission to ‘simplify the use of embedded technology’.

And with this comprehensive offering from modules, cooling solutions and application-ready evaluation and carrier boards, through to design-in training and complete design-in services, congatec is creating a comprehensive COM-HPC ecosystem in which new designs and design sprints for migration from COM Express to COM-HPC Mini are no longer a major challenge.

Box 1:

The congatec carrier board design-in training program

The program includes sections with a special focus on communication interfaces to provide guidance on how to avoid pitfalls in the challenging design of high-speed serial communications – from PCIe Gen 5, USB 3.2 Gen 2, and USB 4 with Thunderbolt, and USB-C, and Ethernet to 100 GbE, including managing sideband signals that need to be deserialized for COM-HPC on the carrier board. The program further shows how best practice designs use interface standards such as eSPI, I²C and GPIOs. Another part is an introduction to congatec’s x86 firmware implementation – from embedded BIOS to board and module management controller functions. Finally, there are sessions on verification and test strategies to address all challenges from initial carrier board design verification to mass production testing.

The COM-HPC and SMARC carrier board design courses are a service of the congatec training academy and require a service subscription. Each participant automatically receives a certificate of successful participation, confirming that they have acquired the relevant knowledge to become a carrier board design expert. Once this knowledge has been acquired, design sprints for migration from COM Express to COM-HPC Mini will no longer constitute a major challenge.

For more information on dates and locations of the congatec training program, as well as detailed course descriptions, please visit https://www.congatec.com/en/designintraining/.