Basingstoke, U. K. – Aerotech had been showcasing its extensive electronics and semiconductor manufacturing expertise at Productronica 2023. At booth 340 in hall B2, the PRO series linear motor stages can be seen live together with the latest release 2.5 of the proprietary motion control platform Automation1. And once again Aerotech presented itself as a system supplier for high-precision positioning tasks in the nano-meter range, from components to complete systems.

Whether manufacturing displays, LEDs, discrete components or micro and nano production, Aerotech’s electronics and semiconductor manufacturing customer base is broad and diverse. With its broad product range specialising in nanometre positioning, Aerotech has carved out a solid niche for itself in the field of high-precision motion technology over the past 50 years. Just earlier this year, the American specialist in precision positioning systems doubled the size of its clean room to serve this customer base.

Simon Smith, European Director at Aerotech: “A large proportion of our customers come from industries with high cleanliness requirements for processes. To keep the amount of airborne particles, particulates or germs as low as possible, sensitive products are manufactured exclusively in cleanrooms.”

In the interest of its customers from the semiconductor and microelectronics industries, Aerotech also ensures constant conditions in the manufacture of its positioning systems and solutions and avoids any contamination.

Integration is becoming increasingly important

Over the years, industrial solutions are becoming smarter and more complex, so that a single company can no longer master all the implementation steps. As a result, the know-how of the supplier is becoming increasingly important. “In recent years, we have worked closely with customers from the electronics industry and have also moved further and further into the area of process automation,” emphasises Simon Smith. “Especially in the semiconductor and electronics sector, many manufacturers have neither the personnel nor the vertical range of manufacture to develop mechanics and control systems in parallel. As a manufacturer of automation systems, we support electronics manufacturers in optimally automating their process with the precision motion components we produce.” In the automation process, Aerotech provides in-depth integration consulting, resulting in either the delivery of individual components, a seamlessly integrated subsystem, or even a complete automation solution. Application training, courses and various other services round off the service portfolio.

Live demo linear motor stages

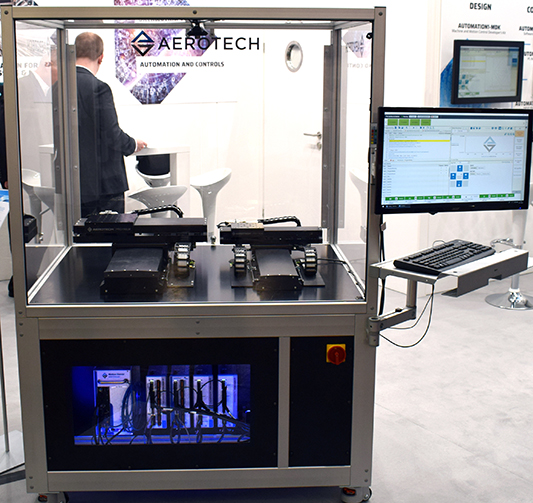

In the electronics industry, Aerotech is known for its high-precision motion solutions for critical applications, including manufacturing systems for micro and nano production, including system peripherals such as galvo scanners and control platforms. As a demo system, linear motor stages of the Aerotech PRO series will be shown in action at the exhibition stand. Trade visitors will be able to see for themselves the latest release 2.5 of the motion control platform: the PRO linear tables are controlled with Automation1. “Using the demo system, we can demonstrate our extensive know-how in the design of these linear tables, including cable management,” emphasises Simon Smith. The robust linear stages travel at high speeds with excellent speed regulation and nano-precise positioning performance and are optionally available with direct drive by a linear motor or with ball screw.

New Automation1 version

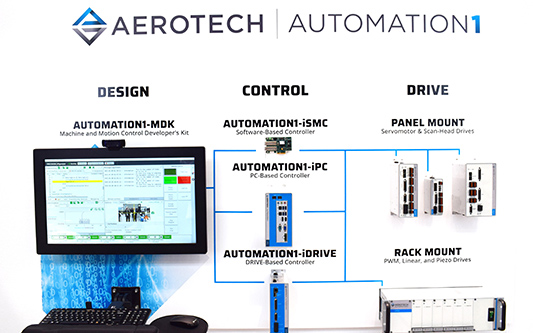

“At the same time, we will focus on the latest version of our control software “Automation1 – Precision Motion Control Platform”, we have installed it as a demo system for Productronica visitors”, adds Simon Smith. Automation1 is also much more than a mere “motion control software”, it also takes over the complete machine control with all components. It has its own software-based motion controller, which makes it easy to control different positioning systems as well as connected components.

The current version 2.5 of the powerful, versatile and user-friendly platform, which is unparalleled on the market, can be seen on the stand. Thus, the motion control experts for precision motion control and automation solutions demonstrate once again that a lot is still possible in Automation1. For example, the galvo and gantry support has been further improved and various new functions have been added, which again noticeably increase the performance and user-friendliness of the platform. In support of this, Simon adds “With additional functions and the improved, user-friendly interface, we are once again demonstrating our competence as a leading supplier of precision motion control and automation solutions.” This makes it even easier to calibrate galvo scanners and change galvo power correction files without having to specially reset the controller. The gantry and encoder functions have also been expanded. The platform now offers a new wizard for homing Gantrys and allows users to output quadrature or clock and direction signals from a specific encoder port. Gantry setup has been greatly simplified with a dedicated checklist module in the sidebar that includes specific steps for configuring a Gantry. In addition, Aerotech developers have optimised the gantry configuration within the device catalogue.