The issue of fuel economy and reduction of emissions has come to the fore in the aviation industry, not only for environmental reasons but simple economic ones as well; the reduction of traffic due to the covid pandemic has put some operators out of business and made the others rethink their business models. With fuel representing around 20-30% of operating costs and every kilo producing 3.15 kg of CO2 [1], there is every reason to reduce fossil fuel consumption, with the ultimate goal of pure electric propulsion. However, with kerosene having an energy density 50x of today’s batteries there are hurdles to overcome. Those batteries don’t reduce in weight as the flight progresses either, as liquid fuel does.

In the meanwhile, ‘More’ Electric Aircraft (MEA) are the focus, with useful weight, efficiency and size gains from replacing pneumatic, hydraulic and mechanical power sources with electric ones. To be most beneficial, a power bus architecture must be devised that provides all of the operating voltages required, with maximum efficiency. Currently, a 270 VDC bus is preferred with DC-DC down-converters for traditional 28 VDC-powered equipment followed by further conversion down to other lower voltages.

SWaP is the metric of MEA DC-DC converter performance

Size Weight and Power (SWaP) are the attributes to optimize in an MEA DC-DC converter and there are many trade-offs to consider, with the bottom line being high safety and reliability. Power designers have many converter topologies to choose from, developed for other applications such as industrial or commercial, but for the MEA environment, and associated performance requirements, the choice narrows. An example will illustrate a typical design process: company Gaia Converter [2] was asked to develop a DC-DC converter in conjunction with the Universidad Politécnica de Madrid, rated at 1 kW output (1.5 kW peak) at 28 VDC from an input that could vary from 220 VDC to 320 VDC including abnormal conditions. The target efficiency was 96% under nominal conditions, size available was just 5.79 cm x 6.1 cm x 1.3 cm and cooling specified via a plate, already at 90°C maximum. Aerospace EMC standards applied along with a requirement that switching frequency should not vary more than +/-15% from nominal.

The design process

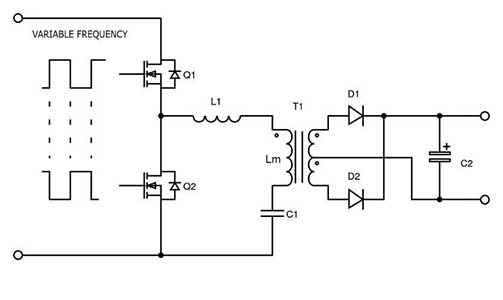

The team already knew that a high-efficiency topology was necessary which implies ‘soft switching’ within the converter to reduce dynamic losses. There are then further options – fixed or variable frequency, resonant conversion or traditional, diode or synchronous rectification and more, but an ‘LLC’ converter was chosen for its high efficiency across the load range, low EMI and simple semiconductor switch drive. The outline is shown in Figure 1.

The LLC converter takes its name from the two inductors formed by L1 and the transformer primary Lm along with the capacitor C1. Together, these form a double resonance in the primary ‘tank’ circuit. Power conversion and variable output voltage is achieved by exciting the tank with a square wave of variable frequency, running up and down the slope of the resonance gain curve. The transformer achieves isolation and scaling of the voltage, and feed back from the DC output controls the excitation frequency.

There are still many variables to consider which affect efficiency, size, cost, electrical performance and EMI, so the designers generated an optimization algorithm to identify the combination of component types and values to best meet the specification. After numerous iterations, GaN HEMT cells were selected for the primary switches for their low losses, a nominal switching frequency of 830 kHz was chosen and values for L1 and Lm calculated for the maximum specified frequency variation. The values of the two inductors were found to very similar, 2.4 µH and 3 µH, which precluded the possibility of L1 being formed from transformer leakage inductance, as this would have made the transformer design inefficient and impractical, so L1 was implemented as a discrete low-loss inductor.

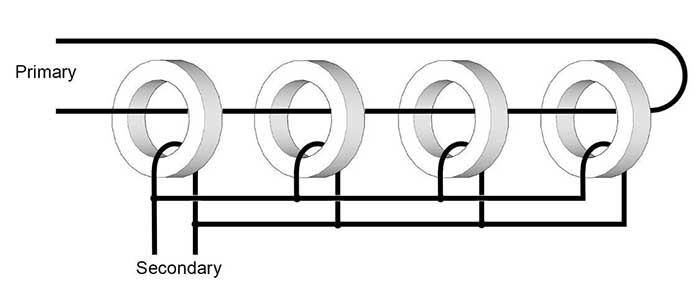

The transformer is also key to high efficiency and a ‘matrix’ design was included which also has the advantages of potentially low profile, low leakage and ease of heatsinking. The matrix transformer principle is illustrated in Figure 2, in this case with stacked toroids with a single primary winding passing through all the elements in series and a single secondary on each toroid paralleled, to give an overall 4:1 conversion ratio.

Practical results

The completed optimized design met the MEA specifications of over 96% efficiency with a transformer temperature rise of less than 30°C. Power density achieved was 32 kW/dm3 in the target volume specified. The all-important switching frequency variation was also limited to less than +/-15%.

References

[1] “Aviation Carbon Offset Programme: Frequently asked questions,” International Air Transport Association, April 30, 2020, iata.org.