Introduction

Integrated gate driver solutions reduce design complexity, development time, bill of materials (BOM), and board space while improving reliability over discrete gate drive solutions. In an industrial environment where high voltages, magnetic fields and noise are present everywhere, reliability is critical to avoid downtime or improper operation. In this environment, circuit designers use galvanically isolated coreless transformer (CT) gate driver to insulate high voltages.

Infineon’s CT gate driver incorporates a magnetically coupled, galvanically isolated technology which uses a semiconductor manufacturing process to integrate on-chip transformer consisting of metal spirals and silicon oxide insulation. The on-chip coreless transformer is to transmits signals between the input and output chip.

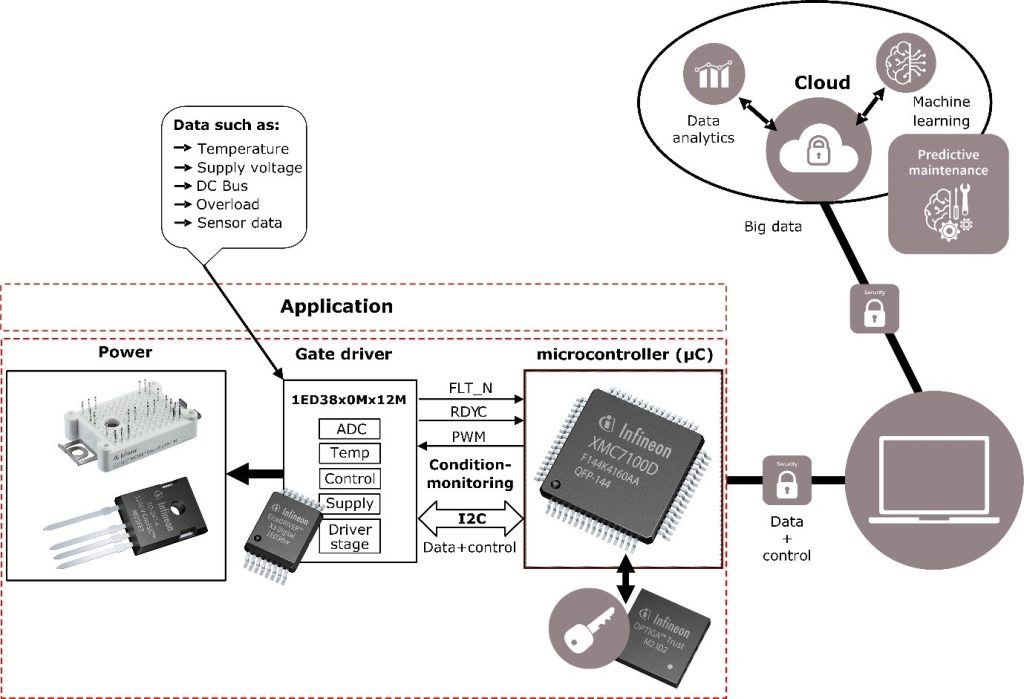

The latest generation of CT-based gate driver is the EiceDRIVER™ X3 Digital. Thanks to an I2C serial interface, the X3 Digital allows for setting system-relevant parameters and can also monitor corresponding data which is available to the application. As a result, flaws in the end product can be detected early and an unintended failure of the application can be prevented. With this expansion of such a system, in which data is collected, evaluated and further processed, the cloud, is referred to as “predictive maintenance”.

Why predictive maintenance?

Predictive maintenance is a method that monitors the health of a system and predicts failures. This is a process of maintaining industrial facilities with robots and machinery such as EV-charging, solar, inverter, and energy storage systems using predictive models. To work with predictive models, continuous sensor data or other relevant information is necessary. With the help of artificial intelligence machine learning software and other special algorithms, which evaluate this data, it is possible to predict the potential failure of a system. In this way, the optimal time for the next maintenance can be accurately determined and prevents the system from failing. In return this means that unnecessary maintenance intervals can be saved and the system’s uptime can be improved.

This maintenance is enabled through data collection and condition monitoring. Software tools such as artificial intelligence and deep learning models, lead to predictive maintenance by using training data, which is only reliable when robust and continuous training data is gathered that accurately represents the types of failures in scope. For this it is important to collect training data for normal operation as well as failure modes which are measured and stored in data systems, either local or cloud based.

EiceDRIVER™ X3 Digital (1ED38x0Mx12M)

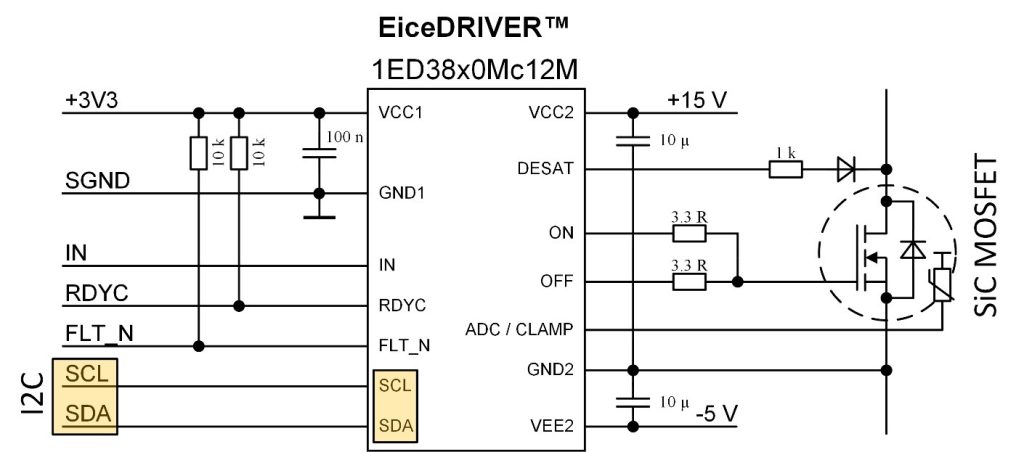

The EiceDRIVER™ X3 Digital family (1ED38x0Mx12M) is a galvanically isolated single-channel gate driver family in a small PG-DSO-16 fine pitch package with a creepage and clearance of 8 mm. The family provides a typical peak output current of ±3 A, ±6 A, and ±9 A and has an extensive digitally adjustable feature parameter set. Adjustable control and protection functions are included to simplify the design of highly reliable systems. All parameter adjustments are done from the input side via the I2C interface (pin SDA and SCL). All logic I/O pins are supply voltage dependent 3.3 V or 5 V CMOS compatible and can be directly connected to a microcontroller. The data transfer across the isolation barrier is realized by the integrated CT technology.

The already mentioned standard I2C bus interface enables the user to configure various parameters of the gate driver and read out measurement and monitor registers. This functionality is key for condition monitoring that enables the desired predictive maintenance.

The X3 Digital family provides two types of registers, 27 configuration and 16 status. All registers are accessible via the I2C bus and are gate driver and application related information which are necessary for the gate driver to work properly in the system. In general, these are written directly after power-up and are information’s like normal switch-off, fault switch-off, DESAT timings and threshold voltages or to enable the ADC.

Measurement and monitoring data that monitor the current operating state of the gate driver or the application are logged in the status registers. These can be read continuously via the I2C bus. The X3 Digital has 16 status registers which are depicted in table 1.

Table 1: Status register of 1ED38x0Mx12M

| Register | Register description |

| RDYSTAT | Status of input side, output side, and gate driver IC |

| SECUVEVT | Output side UVLO events causing a not ready state (sticky bits) |

| GFLTEVT | Indicator of active fault handling |

| FLTEVT | Fault status and events of input side and output side |

| PINSTAT | Status of pins |

| COMERRST | Status of input to output communication |

| CHIPSTAT | Logic status of gate driver IC |

| EVTSTICK | Event indicator (sticky bits) |

| UV1FCNT | Counter of unfiltered VCC1 UVLO events |

| UV2FCNT | Counter of unfiltered VCC2 UVLO events |

| D2ECNT | Counter of DESAT2 events |

| ADCMVDIF | Filtered ADC calculation result of VCC2-GND2 |

| ADCMGND2 | Filtered ADC result of GND2-VEE2 |

| ADCMVCC2 | Filtered ADC result of VCC2-VEE2 |

| ADCMTEMP | Filtered ADC result of gate driver temperature |

| ADCMVEXT | Filtered ADC result of CLAMP-VEE2 |

All registers starting with ADCM (ADCMx) are data from ADC measurements using a free running successive-approximation-register analog-to-digital converter (SAR-ADC). The SAR-ADC´s resolution is 8-bit and the results are digitally filtered with a three-point-two pass moving average filter.

External measurement data is stored in register ADCMVEXT if the external ADC measurement has been enabled in the configuration register. A corresponding application circuit is shown in figure 1.

The register ADCTEMP delivers the junction-temperature of the gate driver through the registers ADCMVDIF, ADCMGND2 and ADCMVCC2 the gate voltages for the power switch can be monitored. This data is always present, regardless of whether the use of the external ADC measurement was enabled or not.

Other status-registers like UV1FCNT, UV2FCNT and D2ECNT are counters. If for example the power supplies VCC1 or VCC2 fall below defined threshold values, a UVLO (under voltage lock out) event will be triggered. The register UV1FCNT and UV2FCNT counting these UVLO events up to FFH and can serve as an indicator for the stability of the power supplies. If these counters reaching FFH, they do not roll over and stop counting. In order to use them again, they must be cleared first using the register CLEARREG. Register D2ECNT counts the DESAT2 events and will stop counting at 3FH. It also needs to be cleared via CLEARREG.

All other status registers are flag based registers. This means that the registers are 8-bit wide, but each bit is assigned to different events or conditions. The corresponding attribute is then displayed via their state 0 or 1.

All status register values shown in Table 1 can be used as sources for predictive maintenance. Figure 2 shows an example of how a complete system with condition monitoring and predictive maintenance enabled by X3 Digital (1ED38x0Mx12M) and a power switch could look like. This example is representative for multiple applications such as mentioned above. It illustrates that all status register values can be forwarded directly to the cloud for advance processing (data analytics, machine learning) to derive information about lifetime and potential required maintenance. In addition, various status signals, e.g. (FLT_N, RDYC), can be used by the microcontroller to act on events like short circuits that require immediate actions to maintain application safety.

Summary

The EiceDRIVER™ X3 Digital family is the perfectly links the analog and digital world. Using digital configurability and extensive monitoring functionality makes the X3 Digital ideal for condition monitoring by collecting system-relevant data. This data is easily accessible by the microcontroller or cloud service to enable predictive maintenance based on advanced data analytics, machine learning and more. The EiceDRIVER™ is the key to predict failures before they occur and keep high-end applications up and running 24/7.