The Indian EV industry is progressing at a rapid rate, with the country proactively participating in the endeavour to reduce its carbon footprint. Prompting the adoption of EVs in the process, the country is working incessantly to become the EV first nation by 2030. As a result, with EVs gaining significant momentum, it becomes more imperative than ever before to boost the battery manufacturing process for enabling a smooth transition to clean transportation.

With the industry bolstering at a phenomenal rate, as per the Mordor Intelligence report, it is estimated that India Electric Vehicle Market will reach 120 billion USD by the year 2030. Levelling up the game, India harbours the ambition to become the next EV manufacturing powerhouse across the world. Working towards streamlining 100% local production of EVs as part of the mission necessitates accelerating the manufacturing efforts to meet the target outlined by the country.

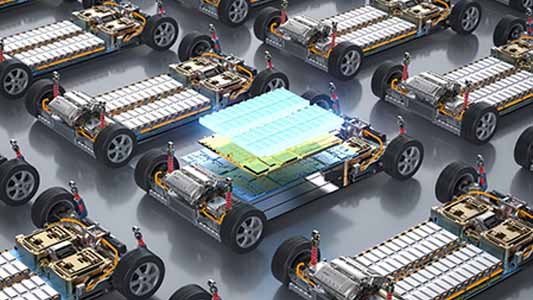

The entire effort to drive the growth of the EV industry aimed at democratizing access to clean transportation across the country underscores the importance of advanced Li-ion battery manufacturing. Li-ion batteries are at the heart of the EV ecosystem and significantly contribute to the unrivalled performance of the electric vehicle. Li-ion batteries are invariably sought by industry players for the wide gamut of advantages they offer. Coming with the ability to deliver high energy per unit weight along with contributing to high energy efficiency, the batteries facilitate optimal performance even at high temperatures. Elaborating on the list of advantages, they boast a high power-to-weight ratio and come with an exemplary low self-discharge capacity.

At the same time, exhibiting better storage density, batteries come in smaller sizes. In addition to this, showcasing excellence in charging and discharging energy safely in the shortest time period, echoes the supremacy of Li-ion batteries in the market. Therefore, Li-ion batteries emerge as the ideal option for giving the desired impetus to the deeper penetration of EVs in the country. Therefore, in order to achieve clean transportation in the country, it is essential to focus on the manufacturing of highly resilient and high-quality battery. This requires Li-ion cells to be manufactured in a highly controlled environment, considering that the presence of moisture at the time of production can account for defective batteries.

As a result, it is recommended to exercise real-time monitoring of humidity throughout the manufacturing and assembling process to maintain it within a narrow range. Installing a desiccant dehumidification system can come in handy for achieving extremely low dew points for processing hygroscopic and moisture-sensitive materials.

In addition to dehumidifiers, the industry should also focus on the sustainable production of Li-ion batteries to enable the transition to clean transportation in the most eco-friendly way. At the time of Li-ion battery manufacturing, NMP is used as a solvent for various processes. The solvent continuously runs the risk of being released into the air as harmful, volatile organic compounds. Containing toxic gases and substances, it is very dangerous in nature, posing a significant threat to the lives of the occupants. Moreover, it is also responsible for adding to the pollution in the air, thereby severely impacting the environment. Looking at the repercussions, as per the law, NMP cannot be released directly into the air, making it mandatory to recover 99.9% of NMP before the release of exhaust into the air.

In order to conduct NMP recovery, VOC abatement technology is required, which is adept at recovering and recycling the VOCs during the battery manufacturing process. The technology bodes well for the collection of evaporated solvents and ensures their conversion to a reusable state. In the process, it achieves the two-fold purpose of preventing harmful chemicals from being released into the air, and at the same time, recovering NMP from exhaust air gives relief from the costly procurement of NMP, as it is very expensive in the market.

Making use of the VOC concentrator, NMP is regenerated from the exhaust air by simply passing the air through the rotor, which comes with the efficiency to absorb NMP. Consequently, the air that is released into the air after recovery is free of NMP and any toxic gases or substances. Therefore, VOC abatement can be considered a ground breaking technology for empowering sustainable manufacturing of batteries. Deploying the technology comes with many benefits, where it significantly minimizes the emission of harmful VOCs during battery manufacturing. At the same time, it helps in complying with the legal VOC reduction mandate outlined by the government.