Optical measurement methods such as laser sensors play an important role in automation technology. For precise distance measurements, laser triangulation sensors are the tool of choice. These measure and test geometric quantities in numerous industrial sectors. For direct integration into the production environment, Micro-Epsilon now presents laser sensors equipped with integrated EtherCAT and EtherNet/IP interfaces. This combines precision and ease of integration in an extremely compact sensor.

Optical measurement methods such as laser sensors play an important role in automation technology. Laser triangulation sensors are used for this purpose.

Measuring sensors used in factory and plant automation must meet numerous requirements. In addition to accuracy, high measurement and processing speeds, as well as measurement results that are as reproducible as possible, are required. There is an increasing demand for modern interfaces that allow easy integration into existing control environments. The laser sensors enable highly accurate displacement, distance and position measurements in a wide range of measurement tasks while offering high cost-effectiveness.

EtherCAT and EtherNet/IP interfaces for precision and flexibility in line applications

Optical measurement methods such as laser sensors play an important role in automation technology. Laser triangulation sensors are used for this purpose.

With the introduction of the new optoNCDT 1900 laser triangulation sensor with EtherCAT, Micro-Epsilon offers a powerful solution for use in factory and plant automation. The latest models are now equipped with an integrated EtherNet/IP interface. The integrated fieldbus interfaces enable easy integration of Micro-Epsilon sensors into Industrial Ethernet control systems.

Due to these integrated, modern interfaces, the sensors offer advantages especially in high speed processes and in the networking of several devices and machines. Integration via EtherCAT or EtherNet/IP facilitates communication, especially in modern plants. Thanks to direct data output, the measured values are available in real time. An oversampling function also contributes to fast acquisition of measurement values.

Highest signal stability for dynamic measurements

For the first time, the optoNCDT 1900 sensors offer a two-step measurement value averaging feature to optimize the signal. The averaging enables a smooth signal at edges and steps while avoiding signal overshoots. This is particularly favorable for fast measurements of moving parts, as a precise signal curve is ensured.

Application diversity in factory and plant automation

The innovative laser triangulation sensors are used wherever high demands are made on precision and ease of integration. The sensors are used, for example, in sophisticated factory automation, automotive manufacturing, 3D printing and measuring machines.

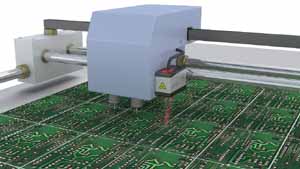

High-resolution fine positioning when printing PCBs

In printing, soldering and assembly processes of printed circuit boards, the exact height positioning of the print head is crucial for a flawless process.

optoNCDT laser sensors enable fine positioning of the print head in printing, soldering and assembly processes of printed circuit boards.

optoNCDT 1900 laser sensors enable precise positioning of the print head. Regardless of surface reflections, these sensors provide precise measurement results which are used to adjust the height and to detect the edges.

Positioning gauge heads in measuring machines

optoNCDT laser triangulation sensors are used for fast positioning of measuring heads in coordinate measuring machines.

Coordinate measuring machines are often used to measure components. optoNCDT laser triangulation sensors are used to position sensor heads quickly. Thanks to their advanced technology, these laser sensors enable fast and accurate positioning of the measuring head.

Position detection of the car body

Laser triangulation sensors are used for high-precision distance measurement on metallic or painted surfaces during car body positioning.

For automated processing of car bodies, an exact determination of the car body position relative to the machining tool is necessary for e.g. drilling, punching or mounting of assemblies. For high precision distance measurement onto metallic or painted surfaces, laser triangulation sensors are used. Here, their insensitivity to ambient light and their high measurement accuracy in particular are a decisive advantages.

Micro-Epsilon India Private Limited

Office No. 101 A | Delta 1 Giga Space IT Park

Viman Nagar – 411014, Pune | Maharashtra

Tel.: +91 20 4913 1030 | Fax: +91 20 4913 1001