Abstract

Gigabit Multimedia Serial Link™ (GMSL™) and Gigabit Ethernet (GigE) are two popular link technologies for camera applications that are often seen in different end markets. This article conducts a comparative analysis of the two technologies in system architectures, key features, and limitations. It will help explain the fundamentals of both technologies and provide insights into why GMSL cameras are a strong alternative to GigE Vision® cameras.

Background

GigE Vision is a network camera interface standard based on Ethernet infrastructures and protocols. It is widely adopted in the industrial space. Analog Devices’ GMSL is a point-to-point serial link technology dedicated to video data transmission and was originally designed for automotive camera and display applications.

Both technologies serve the purpose of extending the reach of video data from the image sensors, while each solution has its own unique features. Over the years, we have seen more GMSL cameras being adopted outside of the automotive space, often as an alternative to GigE Vision cameras.

Typical System Architecture

Image Sensor Connection

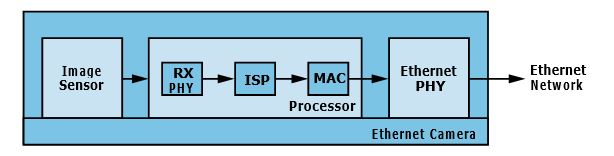

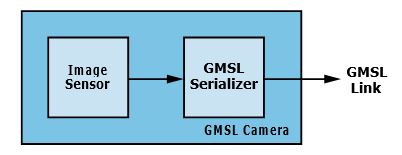

GigE Vision cameras (shown in Figure 1) usually consist of three major components in their signal chain—an image sensor, a processor, and an Ethernet PHY. The processor converts the raw image data from the image sensor into Ethernet frames, and the process usually involves image processing and compression or frame buffering to fit the data rate into Ethernet supported bandwidth.

GMSL cameras’ signal chain (shown in Figure 2) is typically more straightforward with only an image sensor and a serializer. In typical applications, the serializer converts the raw data from the image sensor and then sends it over the link in its original format. Without the need for a processor, these cameras are simpler to design and more suitable for applications requiring a small camera form factor and low power consumption.

Host Processor Connection

GigE Vision cameras are well accepted in the industry for their compatibility with a wide variety of host devices. Gigabit Ethernet port is almost a standard offering on personal computers (PCs) or embedded platforms. Some of the GigE Vision cameras can work with a universal driver for a true plug-and-play experience.

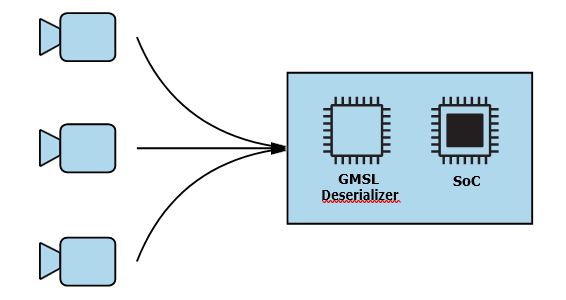

GMSL cameras require deserializer(s) on the host side. In most use cases, the host device is a customized embedded platform with one or multiple deserializers. The deserializers will transmit image data through its MIPI transmitter(s) in the original format from the image sensor MIPI output. For these cameras, a camera driver is required for each customized camera design, just as any other

MIPI camera. However, if there is an existing driver for the image sensor, only a few profile registers or a few register writes are required for the SerDes pair to get a video stream from the cameras to the SoC.

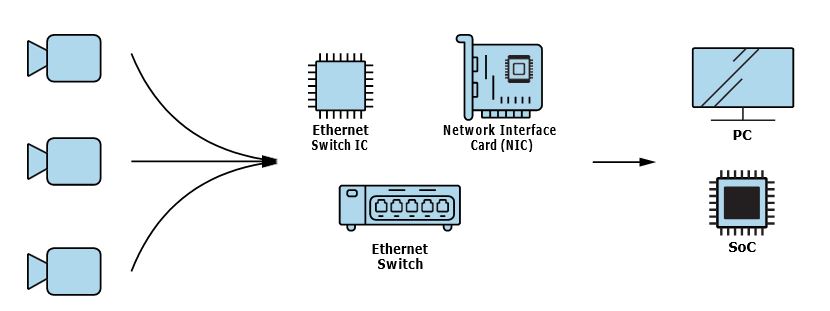

When using only one camera, GigE Vision may have some advantages over GMSL in terms of system complexity since it can be connected directly to a PC or an embedded platform with an Ethernet port. However, when multiple GigE cameras are used, an Ethernet switch is required. This can be a dedicated Ethernet switch device, a network interface card (NIC) with multiple Ethernet ports, or an Ethernet switch IC in between multiple Ethernet ports and the SoC. In some cases, this will result in a reduced maximum total data rate and, worse, unpredictable latency depending on the interface between the cameras and terminal device. See Figure 3.

In a GMSL camera system, one deserializer can connect to up to four links with its MIPI C-PHY or D-PHY transmitter to support the full bandwidth of all four cam- eras. As long as the SoC can handle the total data rate, using one or multiple GMSL devices would not compromise bandwidth or increase too much system complexity.

Feature Comparison

Sensor Interface

GMSL serializers only support parallel LVDS (GMSL1) and MIPI (GMSL2/GMSL3) sensor interfaces. Since MIPI is the most popular image sensor interface for consumer and automotive cameras, a wide range of image sensors can go into a GMSL camera. However, the GigE Vision cameras are just more versatile in the sensor interface due to the processor used inside the camera.

Video Specs

Theory of Operation

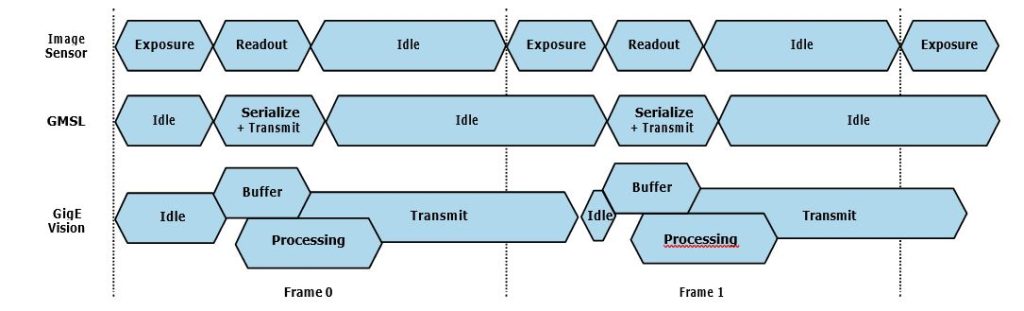

Figure 5 shows an example timing diagram of how data is transmitted from an image sensor to a GMSL link or GigE network in a continuous video stream.

In each frame of a video stream, an image sensor sends out data immediately after the exposure period and then goes to an idle state before the next frame starts. The example diagram better represents a global shutter sensor. For a rolling shutter sensor, there will be an overlap between the exposure and readout period on the frame level since the exposure and readout are controlled individually per row.

GMSL serializers on the sensor side serialize the data from the image sensor(s) and immediately transmit it to the link via its proprietary protocol.

The processor in the GigE Vision cameras will buffer and very often process the data from the image sensor(s) before arranging the video data in Ethernet frames and sending it to the network.

Link Rate

Link rate specifies the theoretical maximum speed of data transmitted on a link and is often the key specification when different data link technologies are compared against each other. GMSL2, GMSL3, and GigE Vision all use discrete, fixed link rates.

GMSL2 supports data rates of 3 Gbps and 6 Gbps. GMSL3 supports a data rate of 12 Gbps, and all GMSL3 devices are backward compatible with the GMSL2 devices using GMSL2 protocols.

GigE Vision follows Ethernet standards. GigE, 2.5 GigE, 5 GigE, and 10 GigE Vision cameras are often found in common applications. As the names imply, they sup- port 1 Gbps to up to 10 Gbps link rate, respectively. The state-of-the-art GigE Vision camera will support 100 GigE with a 100 Gbps link rate.1 For GigE Vision, all higher speed protocols will backward support lower speed protocols.

Although link rate is strongly associated with video resolution, frame rate, and latency, it is hard to make a direct comparison between the two technologies just based on the link rate.

Effective Video Data Rate

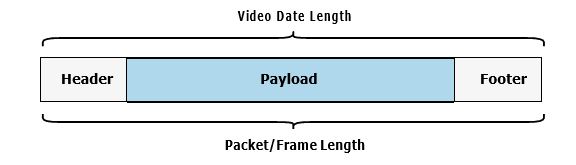

In data communications, effective data rate describes the data rate capacity excluding the protocol overhead, and this concept applies to video data communications as well. Usually, the effective amount of video data being transferred is pixel bit depth × pixel count in a packet or frame. Figure 6 illustrates the relation- ship between effective video data and the overhead.

GMSL transmits video data in packets. GMSL2 and GMSL3 devices use fixed packet sizes, thus the effective video data rate is also well-defined. Take GMSL2 devices as an example. When the link is set up to 6 Gbps, it is recommended to use a video bandwidth of no more than 5.2 Gbps. However, since the link also carries some overhead and blanking time from the sensors’ MIPI interface, 5.2 Gbps reflects the aggregated data rate from all input MIPI data lanes rather than 5.2 Gb of video data per second.

Ethernet transmits data in frames. GigE Vision does not have a standard frame size, and it is usually a part of the software solution trade-off to improve efficiency (benefit of long frames) or reduce delay (benefit of short frames). For these cameras, the overhead is usually no more than 5%. Higher speed Ethernet will reduce the risks of using long frames to achieve a better effective video data rate.

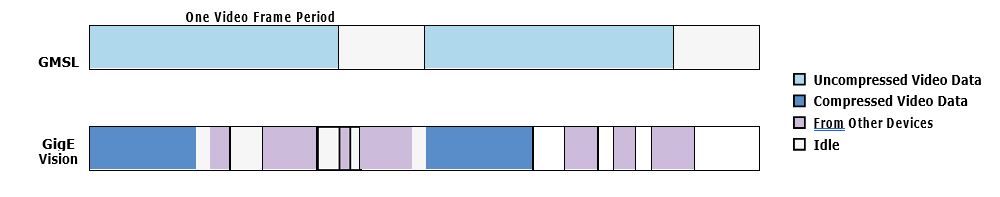

Both technologies transmit data in a bursty way. As a result, the average data rate over a longer period (over one video frame or longer) can be even lower than the effective video data rate during transmission. For GMSL cameras, the burst time solely depends on the readout time from the image sensor, and the burst ratio in real applications can possibly reach 100% to support its full effective video data rate. GigE Vision cameras might be used in a more complex and unpredictable network environment, in which case the burst ratio is often low to avoid data collision. See Figure 7 as an example.

Resolution and Frame Rate

Resolution and frame rate are the two most important specifications for video cameras, and they are the key drivers of higher link rates. For these specifications, both technologies have their trade-offs.

GMSL devices do not offer frame buffering and processing. Resolution and frame rate all depend on what the image sensor or the ISP from the sensor side can support within the link bandwidth, and it is usually a simple trade-off between resolution, frame rate, and pixel bit depth.

GigE Vision’s model is more complex. Although its usable link rate in many cases is slower than GMSL, it may support higher resolution, a higher frame rate, or both at the same time with additional buffering and compression. However, it all comes with the cost of latency, power consumption, and expensive components on both sides of the camera system. In some less common use cases, these cameras also transmit raw image data at a lower frame rate.

Latency

Latency is another key specification of video cameras especially in applications that process data and make decisions in real time.

GMSL camera systems have low and deterministic latency from the input of the serializer/output from the sensor to the output of the deserializer/input of the receiving SoC.

GigE Vision cameras usually have higher and indeterministic latency due to in- camera processing and more complicated network traffic. However, it may not always lead to a longer system-level latency especially when the processing on the camera side counts toward the system image pipeline and is more dedicated and efficient.

Other Features

Transmission Distance

GMSL serializers and deserializers are designed to transmit data up to 15 meters using coax cables in passenger vehicles. However, the transmission distance is not limited to 15 meters as long as the camera hardware system meets the GMSL Channel Specification.

GigE Vision uses Ethernet protocol that can transmit data up to 100 meters using copper cables, or even further using optical fibers, although it may lose some features such as Power over Ethernet (PoE).

PoC and PoE/PoDL

Both technologies are capable of transmitting power and data through the same cable. GMSL uses Power over Coax (PoC) and GigE Vision uses PoE for 4-pair Ethernet and power over data line (PoDL) for single-pair Ethernet (SPE). Most GigE Vision cameras use the traditional 4-pair wires with PoE.

PoC is straightforward and is usually used by default for camera applications with a coax configuration. In this configuration, power and data on the link come from a single wire and there are only a few passive components required for the PoC circuits.

PoE circuits that support a 1 Gbps or higher data rate require dedicated circuitry with active components on both the camera and the host (or switch) side. This makes the PoE feature more expensive and less accessible. It is common for GigE Vision cameras that support PoE to also have a local, external supply option.

Peripheral Control and System Connectivity

GMSL, as a dedicated camera or display link, is not designed to support a wide variety of peripheral devices. In typical GMSL camera applications, the link transmits control signals (UART, I2C, and SPI) to communicate with only camera peripherals such as temperature sensors, ambient light sensors, IMUs, LED controllers, etc. Larger systems that use GMSL as the camera interface usually have other lower speed interfaces such as CAN and Ethernet to communicate with other devices.

GigE Vision cameras normally handle camera peripheral controls with their built- in processor. Being a popular connectivity solution for industrial applications, there are several standard protocols for industrial Ethernet to support diversified machines and equipment, and GigE Vision cameras connect to the network directly with both their software and hardware interfaces.

Camera Triggering and Timestamping

GMSL links support low latency GPIO and I2C tunneling in the order of microseconds on both forward and reverse channels to support different camera triggering/synchronization configurations. The source of the trigger signal in a GMSL camera system can be from either the SoC on the deserializer side or one of the image sensors on the serializer side.

GigE Vision cameras usually provide triggering options in both hardware and software through a dedicated pin/port or an Ethernet triggering/synchronization packet. In typical applications, a hardware trigger is used as the standard approach to provide responsive and accurate synchronization with other cam- eras or noncamera devices. The main problem with the software triggering for these cameras is network delay. Although there are protocols available to improve synchronization accuracy, they can be either not accurate enough (network time protocol (NTP)), synchronizes to millisecond scale2) or not cost-effective (precision time protocol (PTP)), synchronizes to microsecond scale3, but requires compatible hardware).

When a synchronization protocol is used on an Ethernet network, all devices from the same network including GigE Vision cameras will be able to provide time- stamps in the same clock domain.

GMSL does not have timestamping features. Some image sensors can provide a timestamp through the MIPI embedded header, but this is usually not linked with other devices on the higher level system. In some system architectures, the GMSL deserializer will connect to an SoC that is on a PTP network to use a centralized clock. If this feature is required, please use AD-GMSL2ETH-SL as a reference.

Conclusion

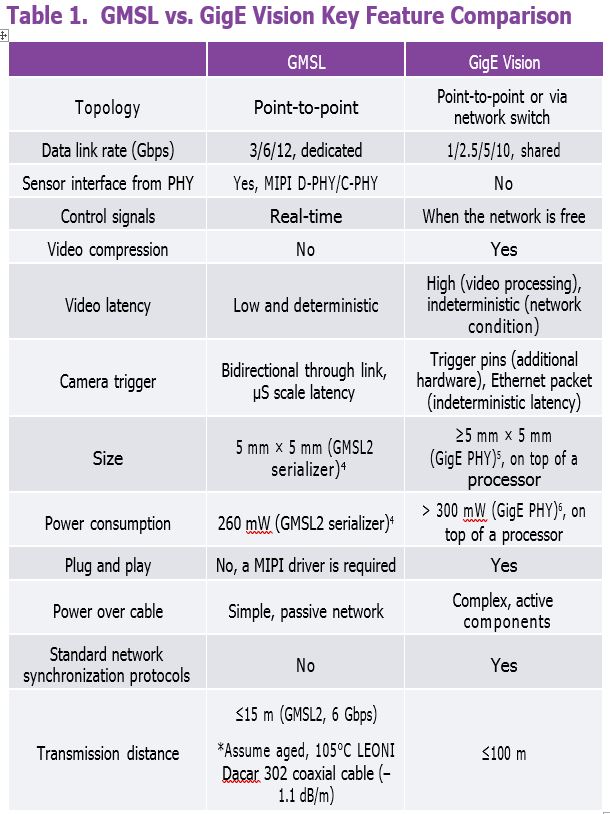

In summary (see Table 1), GMSL is a strong alternative or replacement to the existing GigE Vision solutions. Compared to GigE Vision cameras, GMSL cameras often can provide equivalent or better link rates and features at a lower cost, lower power consumption, and simpler system architecture with a smaller system foot- print. Moreover, since GMSL was originally designed for automotive applications, it has been validated by automotive engineers in harsh environments for decades. It will provide reassurance to engineers and system architects for system development where reliability and functional safety is the key.

References

- “Understanding the Benefits of 10, 25, 50, and 100GigE Vision.” Emergent Vision Technologies Inc., 2023.

- David L. Mills. “Internet Time Synchronization: The Network Time Protocol.” IEEE Transactions on Communications, Vol. 39, Issue. 10, October 1991.

- “IEEE Standard for a Precision Clock Synchronization Protocol for Networked Measurement and Control Systems.” IEEE, July 2008.

- MAX96717. Analog Devices, May 2023.

- “Single Port Gigabit Ethernet PHY.” MaxLinear, February 2023.

- ADIN1300. Analog Devices, Inc., October 2019.

About the Author

Kainan Wang is a systems applications engineer in the Automotive Cabin Experience (ACE) Group at Analog Devices in Wilmington, Massachusetts. He joined ADI in 2016 after receiving an M.S. degree in electrical engineering from Northeastern University in Boston, Massachusetts. Kainan has been working with 2D/3D imaging solutions from hardware development, systems integrations to applications development. Most recently, his work focus is to expand Analog Devices automotive cabin technologies into other markets beyond automotive.