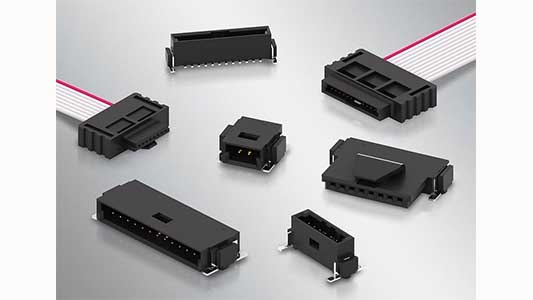

Harwin has announced the expansion of its Kontrol range of industrial board-to-board interconnects (BBi), adding single row connectors and cables to the 1.27mm pitch (0.05″) connectors. The range has been created to bridge the gap between high-end connectors and established pin header and socket solutions.

The launch adds to Harwin’s existing dual-row Kontrol connectors, extending the range with 49 new products – 21 SMT connectors and 28 double-ended cable assemblies – that include pin-count options of 2, 3, 4, 6, 8, 10 and 12.

SMT Connectors

All new SMT connectors in the series are available in vertical (male only) or horizontal (male and female) mounting options, with full shrouding and recessed contacts incorporated to prevent damage to the pins.

To improve assembly, the connectors have been polarized to prevent mis-mating, and also feature a tolerance to misalignment, with a permissible linear misalignment of up to 0.075mm and an allowable misalignment angle of 4.3o.

The latched design enables tool-free mating and unmating, while surface mount tabs have been implemented to improve the retention force holding the connectors to the PCB. Location pegs have also been incorporated to assist with correct board placement and inhibit movement while soldering.

Double-Ended Cable Assemblies

The new Kontrol male and female double-ended cable assemblies include in-line connectors and UL-Specification 26 AWG ribbon cable, with an option of 150mm and 300mm options available.

Like the SMT connectors, full shrouding, latches and polarization have been implemented to protect contacts and improve secure and blind mating.

Technical Specifications and Availability

The new single row products meet the same high electrical and reliability specifications as the existing Kontrol line-up, with a current rating of 1.2A per contact, and a 25mΩ contact resistance. The connectors are qualified up to 500 mating operations, operated across a 170oCC temperature range (-55 to +125oC, board-to-board / -20-105oC cable-to-board and cable-to-cable) and have been tested to withstand vibration forces of 20 G for up to 12 hours.

All connectors are available in tape and reel packaging for automated assembly processes, with disposable pick-and-place caps included where needed.

John Feaster, Harwin’s BBi product manager said: “Industrial and embedded applications are needing to operate under ever more stringent conditions, deployed with tighter constraints on space and in harsher environments. These new single row Kontrol connectors and cable assemblies give designers the greater flexibility they need when creating designs that exceed both today’s and future requirements.”

To find out more about Harwin’s Kontrol range visit: https://www.harwin.com/bbi-range/kontrol