Have you ever imagined, what if the import levels of India decrease and export levels increase ? Want to know how ? It’s possible by adopting to the Make in India initiative for EMS (Electronic Manufacturing Service). It refers to companies that design, manufacture, test, distribute, and provide return/repair services for original equipment manufacturers’ electronic components and assemblies (OEMs). Make In India initiative should be adopted to make this dream a true reality, by doing this the Indian economy can soar to new heights because it has potential and this revolution has already begun.

In order to be self-reliant and grow to a 5 trillion dollar economy, it is crucial for India to boost electronic manufacturing. With an emerging startup ecosystem in India and the formation of resilient supply chains post-pandemic. Electronic manufacturing services can play an important role in boosting India’s electronic manufacturing sector.

What is Electronic Manufacturing Service?

Companies that manufacture electronic circuits or systems sometimes outsource this manufacturing to third-party companies. This may include the entire process from design and development, procurement of components, their assembly, testing and the packaging of electronic products. Sometimes companies also outsource a particular aspect of manufacturing given their lack of experience or specialization.

Electronic manufacturing services make it possible for companies to focus on their core functions without having to worry about the manufacturing process.

Electronic Manufacturing Industry and its Potential:

The Electronic Manufacturing Industry has been growing steadily over the past decade, thanks to the rising demand for electronic products throughout the globe. However, the industry is yet to become big in India. Recently India has come up with a National Policy on Electronics and the Modified Special Incentive Package Scheme which will help the growth of this industry.

With the introduction of the Internet of Things (IoT) and 5G services, global demand is expected to rise steeply as well. Advances in manufacturing processes and materials have further aided the growth of this industry. With rapid infrastructure growth and a focus on skilled labor, the future of the EMS industry in India looks promising.

Some specific areas with high potential demand are smartphones and tablets and home appliances due to increasing income in developing countries and the decreasing cost of products. Technological advancements have made the IoT a reality.

There has been a constant push for electric vehicles by governments across the world due to the climate crisis. Last but not least, Augmented and Virtual reality provides immense opportunities for future growth of demand for electronic products.

What are the Steps taken by the Government to boost EMS?

- Establishing electronic manufacturing clusters.

Under this, the Ministry of electronics and IT provides financial assistance for the development of infrastructure and common facilities in clusters of electronic manufacturing units.

- Production Linked Incentive (PLI) scheme.

Under this, the government would provide incentives to companies that manufacture electronic products in India.

- National Policy on Electronics.

It aims to provide a conducive environment for the growth of the electronic manufacturing industry in India.

How does Evolute Cleantech Solutions support the production of electronic goods?

Make In India initiative is something that actually fascinated us to start this journey, we know that we have that potential as a country to achieve new heights since then we are on a quest to expand our horizons.

Our EMS capabilities including advanced equipment, best in class SMT lines, Box assembly lines for complete Product manufacturing, especially for high-end embedded products & testing with a highly motivated 300+ work force cater across medical & healthcare, agriculture, industrial automation, solar applications, household equipment, defense, BFSI, Transit, e-Governance, retail sectors all over India and the World, laced with Technology at its core, enabling our mission of Techpowering the World®.

Evolute Cleantech Solutions, an integral part & manufacturing arm of the Evolute Group is located at Vasai, near Mumbai, with a state-of-the-art manufacturing facility spanning a large 30,000 sq. ft. area with smart manufacturing capabilities for Energy Storage Solutions (ESS), customized battery packs, EV batteries, Smart Batteries, Battery Management Solutions (BMS), in the Cleantech space as well as manufacturing solutions for POS and payment devices, biometric authentication, thermal printers and more in the Fintech space.

Evolute Cleantech Solutions can serve various industries like consumer electronics, medical, aerospace, automotive, industrial, and many more. Some of the benefits of working with evolute include access to specialized equipment and expertise, cost savings, and flexibility in production volumes.

Our Capabilities

Surface-Mount Technology (SMT)

Our in-house SMT Line is the best in its class, with a capacity of 120000 CPH and features such as an automatic stencil printer, pick and place capability, automated optical inspection (AOI), automatic reflow, and more. It can handle most 0201 assemblies as well as complex 8-layer PCB arrays. Our well experienced and trained manpower is equipped to handle complex processes and managing deliveries on a turn key basis. We ensure automation of processes that are controlled with ERP & SAP accounting systems for most effective execution.

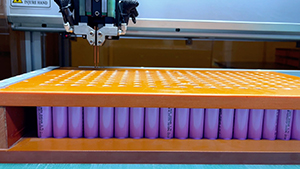

Battery Packs Manufacturing

We are a full-service custom battery manufacturer with in-house design and engineering capabilities. Our team has extensive experience with multiple battery chemistries and battery pack assemblies as per customer needs. We work closely with customers on all our projects starting with design, concept through prototyping and testing to large-scale manufacturing from our smart factory at Vasai.

Box Building

Our skilled EMS Team can integrate assembly and box build capabilities to manufacture custom product as per client needs and specifications. Additionally, Evolute’s EMS vertical has a team of experienced technicians who can perform functional and testing processes based on specified criteria.

Our box build lines are fully equipped with test set up for functional tests of payment terminals and handheld devices that serve as an enabler of financial inclusion.

We have been certified by Mastercard Visa TQM for our facility as well as processes to authorize us in manufacturing of complex payment terminals & micro-ATMs.

Its services supporting the manufacturing of electronic goods include energy efficiency and waste reduction services, energy management systems, waste management systems, and others. Furthermore, these services help to reduce energy consumption and improve the environmental impact of electronic goods production.

What is the Future of EMS?

The future of EMS looks bright with the growing demand for electronic products. There has been a growing trend of using automation and technologies like robotics and AI in the manufacturing process. Miniaturization and high-density packaging would also play a crucial role in the upcoming era. With an increased emphasis on fighting climate change, sustainability is going to be at the epicenter of the manufacturing process. Furthermore, data analytics would also become increasingly relevant, and the focus on flexible manufacturing would increase. The EMS industry will also see an increase in supply chain management, improving the speed and efficiency of procurement, logistics and inventory management.