Impossible Objects has announced that it will exhibit at the 2023 IPC APEX EXPO, scheduled to take place Jan. 24-26, 2023 at the San Diego Convention Center in California. The company will discuss its capabilities for 3D printing composite tools and parts that typically would be machined or injected molded in Booth #2902.

Impossible Objects’ high-speed, high-performance low-labor CBAM process is perfect for NPI projects, since it is able to both produce inexpensive complex quality tools for customers in less than a week and be cost-effective in low-volume manufacturing of up to 10,000 units when compared to injection molding. In particular, Impossible Objects can do low-cost prototyping with finished product quality.

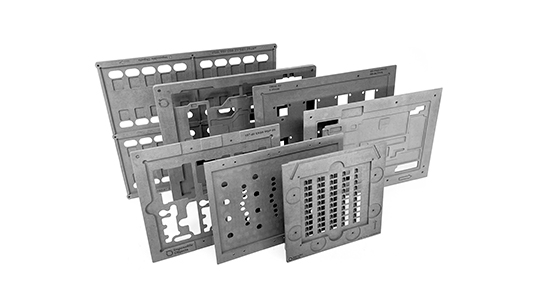

In many cases projects can be held up for months due to tooling for electronics or other manufacturing processes and cost tens of thousands of dollars. Impossible Objects’ automated manufacturing is changing that with turn-around times of shorter than a week, in-house design services for tooling, and pricing that’s independent of complexity and lower than machining. All of this without sacrificing an inch in material properties: Impossible Objects’ Carbon fiber – PEEK composite parts can withstand temperatures in excess of 500°F and virtually any caustic manufacturing environment used today, making them ideal for many tooling applications. This unique set of qualities makes Impossible Objects ideal for NPI.