SAN DIEGO, CA ― Today, Intraratio announced AICard, which harnesses the power of artificial intelligence and machine learning to empower manufacturers to make informed decisions quickly and accurately regarding product quality and manufacturing line performance and optimization.

“We are proud to formally release AICard into the advanced electronics manufacturing market, for real-time automated AI/ML outlier detection, bringing a massive competitive advantage to our customers,” said Ryan Gamble, CEO and Founder of Intraratio. “AICard is accessible and rapidly deployable today, regardless of customer size. This is in direct contrast to existing solutions in the market today that are nothing more than costly data science experiments, often resulting in pilot purgatory. Our solution immediately optimizes workforce utilization, by automating out the data mining phases of both exception identification and cataloging the source, in order to provide engineering and management with insights that drive immediate process improvements.”

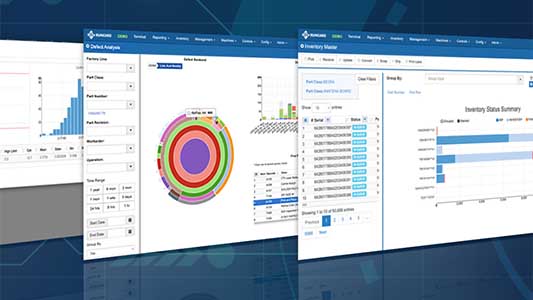

Manufacturing companies frequently encounter the challenge of collecting and analyzing large amounts of data to pinpoint product defects, inefficiencies, and areas for improvement. AICard’s most noteworthy aspect is its advanced automation, which rapidly identifies and reports anomalies in real-time.

This groundbreaking capability provides manufacturers with a comprehensive view of outlier data for their products, streamlining critical decision-making processes. Unlike traditional methods that rely on manual model creation and upkeep, AICard automates these tasks, freeing up valuable time for users to delve into data analysis rather than collection. Additionally, AICard seamlessly integrates with our RC/DC data schemas, allowing users to analyze and report data without the hassle of managing extra data pipelines.