Plymouth, WI — Kurtz Ersa Inc., a leading supplier of electronics production equipment, is excited to announce its participation in the 2025 IPC APEX EXPO at the Anaheim Convention Center. Visitors to Booth #824 will have the opportunity to experience the latest advancements in soldering and rework technology, including the VERSAFLOW ONE FF, VERSAFLOW ONE XF, VERSAFLOW 4/VERSAFLEX and the HR 600P Rework System.

VERSAFLOW ONE FF – The Gold Standard in Selective Soldering

The VERSAFLOW ONE FF offers high performance inline selective soldering for high-end production environments. Engineered for maximum throughput and modularity, it triples production capacity while maintaining exceptional flexibility. Key features include an intuitive operating system and proven control systems that ensure the highest level of process reliability.

VERSAFLOW ONE XF – Revolutionizing Inline Soldering

The VERSAFLOW ONE XF introduces groundbreaking advancements in compact inline selective soldering. With its dual-pot soldering module, the system is capable of simultaneous soldering on two assemblies within a PCB panel, increasing productivity by up to 50%. Unique X-variability technology enables soldering joints of varying sizes using different nozzle diameters, all without halting production. The ability to operate up to two soldering modules further enhances throughput, making this system a game-changer for economic efficiency and soldering quality.

VERSAFLOW 4 featuring VERSAFLEX – Flexibility and Efficiency Redefined

The VERSAFLOW 4 featuring the VERSAFLEX Soldering Module provides flexibility for soldering processes. Designed for mixed production, the module eliminates downtime by automating mechanical adjustments and optimizing cycle times with CAD-Assistant 4.

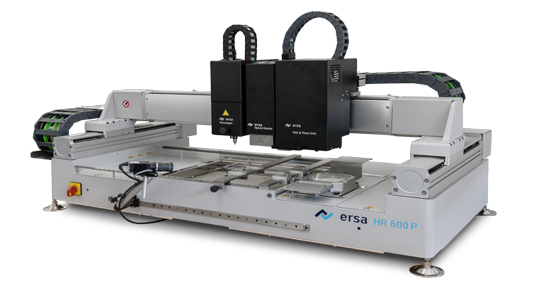

HR 600P – Precision Rework with Innovative Scavenger Technology

The HR 600P Rework System sets a new benchmark with its automated residual solder removal module (SC 600 Scavenger), which removes solder from PCBs without mechanical contact, ensuring precision and preventing damage. Its hybrid heating head combines infrared and convection heating for uniform thermal control, supported by a closed-loop temperature system and high-precision axis movements.

Designed for components ranging from 1 x 1 mm to 60 x 60 mm, the HR 600P supports applications for both large BGAs and miniature components, with advanced tools like the Ersa Dip&Print Station for precise flux or solder paste application.

Kurtz Ersa invites attendees to Booth #824 to witness live demonstrations of these cutting-edge solutions and discover how their innovative technologies can optimize production efficiency, enhance reliability, and reduce operational costs.

For more information about Kurtz Ersa Inc., visit www.ersa.com.