The lighting industry has undergone a remarkable transformation over the past few decades, with LED (Light Emitting Diode) technology at the forefront of this evolution. Central to this innovation are LED chips, the tiny semiconductor components that form the heart of every LED light source. As the demand for energy-efficient, long-lasting, and environmentally friendly lighting solutions grows, the LED chip market is expanding rapidly, powering a wide range of applications from household bulbs to automotive lights and large-scale commercial installations.

The LED chips market is experiencing robust growth driven by increasing demand for energy-efficient and long-lasting lighting solutions across residential, commercial, and industrial sectors. As the core component of LED lighting systems, LED chips are continuously evolving with advancements in semiconductor materials, thermal management, and miniaturization technologies

What Are LED Chips?

LED chips are microscopic semiconductors that emit light when an electric current passes through them. These chips are fabricated using materials such as gallium nitride (GaN), gallium arsenide (GaAs), or indium gallium nitride (InGaN), which determine the wavelength—and consequently, the color—of the emitted light.

LED chips are embedded inside LED packages or modules and can vary greatly in size, structure, and performance characteristics. They are the core component responsible for the efficiency, brightness, and color rendering of LED products.

Types of LED Chips and Their Differences

Understanding the differences between various LED chip types is crucial for manufacturers and consumers alike. According to InstyleLED, LED chips can be broadly categorized based on their construction, size, and application:

1. SMD (Surface-Mounted Device) LED Chips

SMD chips are mounted on a circuit board and encapsulated with a resin or silicone lens. They are among the most common types of LED chips used in general lighting. SMD LEDs are compact, versatile, and can produce a broad range of colors. They are widely employed in LED strips, bulbs, and panel lights.

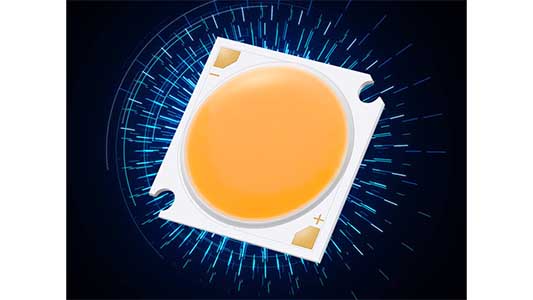

2. COB (Chip on Board) LED Chips

COB technology involves mounting multiple LED chips closely together on a single substrate to form a uniform light-emitting surface. This design offers higher lumen density and better heat dissipation compared to traditional SMDs, resulting in brighter and more energy-efficient lighting. COB LEDs are preferred in high-power applications such as floodlights, downlights, and automotive headlights.

3. Flip-Chip LED Chips

Flip-chip LEDs are designed to enhance thermal performance by flipping the chip upside down so that the semiconductor junction is directly attached to the substrate. This method reduces heat resistance and increases luminous efficacy, making flip-chip LEDs ideal for high-power and high-brightness applications.

4. Mini LED and Micro LED Chips

Recent advances have introduced mini and micro LED chips, which are much smaller in size but capable of producing highly detailed and precise lighting. These chips are increasingly popular in display technologies such as TVs, smartphones, and augmented reality devices due to their excellent color accuracy and contrast ratios.

Technological Innovations Driving LED Chip Performance

Companies like Cree, a pioneer in LED technology, continually push the boundaries of LED chip innovation. Cree’s patented Silicon Carbide (SiC) substrates enable higher voltage operation and superior thermal conductivity, which enhance both the brightness and lifespan of their LED chips. Their product lines, such as the XLamp series, are widely regarded for high performance in demanding lighting conditions.

Thermal management is a key area of innovation since excessive heat can degrade LED performance and lifespan. Advances in chip design, such as improved heat sinks, substrate materials, and packaging techniques, are critical in maintaining optimal operating temperatures.

Another technological leap involves the development of high Color Rendering Index (CRI) LED chips. High CRI LEDs produce light that closely resembles natural sunlight, making colors appear more vivid and true to life. This is particularly valuable in retail, art galleries, medical lighting, and photography.

Applications of LED Chips

LED chips are versatile components that serve diverse markets:

- General Lighting: LED bulbs, panel lights, and streetlights rely heavily on efficient LED chips to reduce energy consumption while maintaining brightness and color quality.

- Automotive Lighting: Headlights, brake lights, and interior lighting in vehicles increasingly use high-power LED chips for durability and design flexibility.

- Display Technology: Mini and micro LED chips have revolutionized display panels, offering improved brightness, energy efficiency, and lifespan compared to traditional LCD and OLED displays.

- Specialty Lighting: Applications like horticultural lighting, UV curing, and medical devices depend on customized LED chips designed for specific wavelengths and power outputs.

Market Growth and Trends

The LED chip market is experiencing rapid growth fueled by the global push for energy-efficient lighting and sustainable solutions. According to industry analysis from sources like Polluxteam, LED chip adoption is rising due to falling costs, regulatory pressures to phase out incandescent and fluorescent lamps, and advancements in chip efficiency and color quality.

Asia-Pacific remains a dominant region in LED chip manufacturing, driven by countries like China, South Korea, and Taiwan. Leading companies such as Cree (USA), Nichia (Japan), and Seoul Semiconductor (South Korea) compete globally to innovate and capture market share.

Increasing demand for smart lighting systems also influences LED chip development. Integration with sensors, wireless control, and IoT compatibility requires chips that support dimming, color tuning, and extended lifespans under dynamic conditions.

Challenges and Future Outlook

Despite impressive progress, LED chip manufacturers face challenges such as supply chain disruptions, raw material price fluctuations, and intense competition driving down margins. Ensuring quality and reliability while maintaining cost-effectiveness is crucial.

Looking ahead, the future of LED chips lies in continued miniaturization, higher efficiency, and enhanced integration with smart technologies. Micro and nano-scale LEDs are expected to open new frontiers in display and lighting applications, combining ultra-high resolution with energy savings.

Sustainability will also remain a focal point, with eco-friendly manufacturing processes and recyclable materials becoming industry standards.

Conclusion

LED chips have fundamentally transformed the lighting and display industries by offering superior energy efficiency, longevity, and design flexibility. From humble beginnings as small semiconductor devices, they now power a vast array of applications worldwide. As technology advances and demand surges, LED chips will continue to illuminate not only our homes and workplaces but also the path toward a sustainable, high-tech future.

For businesses and consumers alike, understanding the different types of LED chips and their capabilities is key to making informed decisions in this dynamic market. With leaders like Cree pushing innovation boundaries and a robust global manufacturing base, the LED chip market is poised for significant growth and exciting new developments in the years to come.