Author: Daniel Parr, Technology Analyst at IDTechEx

The battery industry is facing increasing pressure to develop new chemistries and materials to keep up with rising energy density and sustainability demands. The traditional materials discovery process involves physics-informed trial-and-error, which is both expensive and time-consuming. Machine learning methods, specifically materials informatics for discovering electrolyte, electrode, current collector and packaging materials, could provide a necessary avenue for accelerating the battery development process. For more details on materials informatics for batteries, see IDTechEx’s recent report: “AI-Driven Battery Technology 2025-2035: Technology, Innovation and Opportunities”.

Materials informatics describes a field of machine learning in which data science is used to screen and discover materials for specific use-cases. It is a technology that has existed for several decades, and a successor to bio-informatics, revolutionizing the pharmaceutical industry. The application of materials informatics requires a database of candidate materials for an agent to be trained on. Each of these materials will be fully defined by a set of descriptors, e.g. chemical elements, lattice structure, density, viscosity, electron density, etc. These descriptors must match the targeted application, so that conclusions can be drawn regarding the effectiveness of the material. For battery materials, example descriptors include redox potential, diffusion coefficient, density, bond dissociation energies, dielectric properties, viscosity, etc. Without a complete and well-described training database, the application of materials informatics will lead to misfitting. Underfitting refers to cases where the predictive agent is undertrained, which leads to a limited mapping between descriptors and properties. Overfitting refers to cases where the agent is overtrained relative to the complexity of the problem, which limits predictive capacity outside of the initial training set. This is especially common in materials informatics, where the training set size may be more limited than in other machine learning fields.

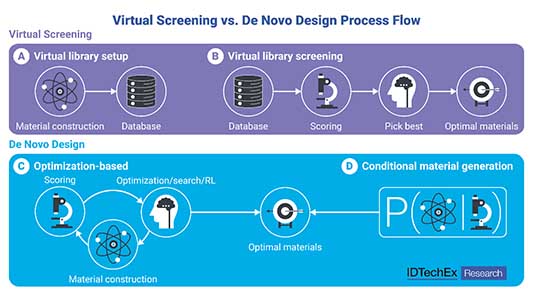

Illustration of virtual screening and de novo design process flows. Source: IDTechEx

The more developed use case for materials informatics is in virtual screening. This describes the situation where a database of candidate materials has already been generated, and agents are employed to predict properties and remove low-potential materials, thereby reducing the number of materials that need further testing. Regression methods may be used to first predict continuous property values, with classification for discrete values. These values will then be mapped onto an n-dimensional space where n is the number of properties/descriptors, and further grouped into high- and low-performing materials through a scoring agent.

An emerging technology is de novo design, describing materials informatics that utilizes generative AI to design entirely novel materials. A scoring agent and a generative agent work in tandem to score theoretical materials, eventually selecting a candidate with the highest potential for the given application. The process can be broken down into the following steps:

- Generative agent proposes a material

- Scoring agent assesses performance of the material (similar to virtual screening)

- Scoring agent weights the material and returns this weighting to the generative agent

- Generative agent proposes a new material using weighting of previous materials to decide how the material should be constructed

- These steps are repeated, until a suitable candidate is identified

Each approach has different challenges associated with it. Virtual screening can only be used to screen known materials, and the total space that can be explored is limited. Further, for emerging battery chemistries, the database for known materials is less populated, so a screening agent’s predictive capacity is limited. Meanwhile, de novo design is relatively immature, and though it has seen some success, most of this is in research rather than in the commercial world. Completely novel materials also lack existing supply chains, and as such they are expensive to synthesize as they do not benefit from economy of scale.

Generally, IDTechEx predicts that well-established chemistries will heavily favor virtual screening approaches over de novo design, while less established chemistries will require de novo design. Schrödinger, a major player in the materials informatics space, suggested that its current client base employs roughly a 50/50 proportion of each. However, it is likely that as new chemistries become more mainstream and de novo design shows more results, de novo design will become the primary materials informatics tool for battery material development. IDTechEx predicts that materials informatics will become a necessary part of the battery development over the next decade, especially as new chemistries like lithium-metal become more common.

To find out more about this IDTechEx report, including downloadable sample pages, please visit www.IDTechEx.com/AIBattTech.

For the full portfolio of batteries and energy storage market research available from IDTechEx, please see www.IDTechEx.com/Research/ES.