Mohan Babu University (MBU) has been at the forefront of fostering innovation and research among its students, providing them with unparalleled support to explore real-world challenges and develop cutting-edge solutions. The project on Monitoring Toxic Gases Using Nanotechnology and Wireless Sensor Networks is a testament to the university’s commitment to enabling students to undertake advanced, impactful projects. This initiative, led by engineering students Patil Nagalakshmi, Shaik Riyaz, Poola Pavan Si Kiran, and Reddy Sai Krishna Vamsi, under the mentorship of Dr. N. Ashok Kumar, M.Tech., Ph.D. Professor, Department of ECE, reflects the collaborative and dynamic academic environment at MBU.

This project presents a highly innovative gas detection system that leverages the power of nanotechnology and wireless sensor networks (WSNs) to provide real-time, efficient monitoring of toxic gases—ensuring enhanced safety for human life and critical infrastructure.

Project Overview

In both industrial and environmental settings, undetected gas leaks pose a serious threat to safety and security. Current detection systems, while useful, often lack the speed and sensitivity required to prevent disasters before they happen. This student project aims to address this challenge by developing a cutting-edge gas detection system that combines highly sensitive nanotechnology-based sensors with the efficiency and scalability of WSNs. The result is a solution that offers unparalleled accuracy, real-time data transmission, and swift, proactive alerts.

The Problem Addressed

Gas leaks in industrial, residential, and public settings are a pervasive danger, causing potential harm to both people and property. Despite existing safeguards, many detection systems fail to respond swiftly enough to mitigate risks. This project directly addresses this gap by providing a reliable, responsive detection mechanism capable of monitoring a wide range of hazardous gases in real time.

Key Features and Innovations

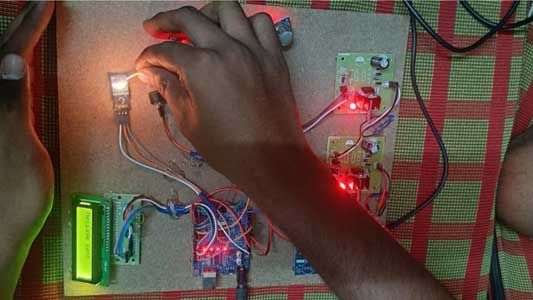

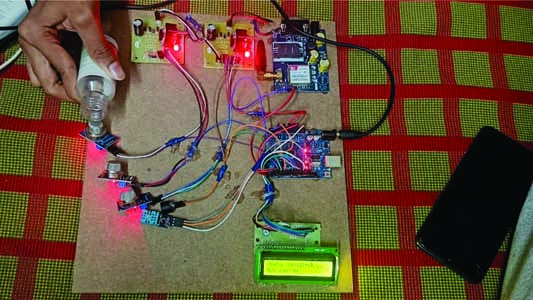

- Nanotechnology-Driven Sensors: Utilizing cutting-edge materials such as graphene and carbon nanotubes, the system significantly enhances gas adsorption and detection sensitivity. This ensures rapid identification of even trace amounts of harmful gases like LPG, methane, and carbon monoxide at parts per million (ppm) and parts per billion (ppb) levels.

- Wireless Sensor Networks (WSNs): By integrating the sensors into a scalable WSN, the project enables continuous, large-scale monitoring with real-time data transfer and instantaneous alerts across vast areas, ensuring a faster response time in critical situations.

- Advanced Communication Technologies: With GSM and IoT connectivity, the system allows for remote monitoring, enabling users to receive alerts and take action from anywhere, providing scalability for diverse applications.

Real-World Applications

The versatility of this gas detection system opens up multiple avenues for real-world application, including but not limited to:

- Industrial Safety: Continuous monitoring of toxic gases in factories, refineries, and other high-risk industrial zones.

- Environmental Monitoring: Real-time tracking of harmful gas emissions for environmental protection and regulatory compliance.

- Home and Building Safety: Detecting dangerous gas leaks in residential areas, reducing the risk of accidents and fatalities.

- Healthcare: Enhancing patient safety in medical facilities by monitoring air quality in critical care environments.

- Agriculture: Ensuring safe air conditions in agricultural settings, particularly in controlled environments like greenhouses.

Advantages of the System

- Exceptional Sensitivity and Accuracy: Detects gases at microscopic levels, allowing for early intervention before the situation escalates.

- Scalability: The system can be easily adapted and expanded for various settings, from small residential spaces to large industrial facilities.

- Energy Efficiency: Designed for longevity and continuous operation, the system is optimized to function with minimal energy consumption.

- Cost-Effectiveness: By leveraging the versatile Arduino platform and cost-efficient sensors, the system provides a powerful yet affordable solution for real-time gas monitoring.

Conclusion

This student project demonstrates a significant leap forward in the field of environmental and industrial safety. By combining the strengths of nanotechnology and WSNs, the system offers an advanced, comprehensive solution to the growing issue of gas leaks. Its real-time monitoring, high sensitivity, and scalability position it as a potential game-changer in multiple sectors, from industrial safety to environmental protection.