Conventional discrete SiC MOSFETs rely on an external thermally conductive and electrically isolating material for heatsink isolation. This approach increases thermal resistance from junction to heatsink, complicates thermal management, and adds challenges to both automated and manual assembly processes. Additionally, limited thermal conductivity restricts power and current handling, preventing optimal chip utilization. The Littelfuse ISO247 package, incorporating high-performance silicon nitride (Si₃N₄) ceramic, overcomes these issues by enhancing SiC chip utilization and improving the performance of SiC MOSFET-based applications.

High Performance Ceramic based Discrete Isolated Package

The ISO247 is part of the ISOPLUS™ family of internally isolated discrete power semiconductor packages. This family incorporates direct bonding copper (DBC) substrates with aluminum oxide (Al₂O₃) ceramic, a technology originally pioneered by IXYS Semiconductor (now part of Littelfuse) in 2003. Designed to conform to the JEDEC TO-247AD outline, the ISO247 ensures pin compatibility with standard TO-247 packages. It supports a range of semiconductor technologies, including Si/SiC MOSFETs, IGBTs, and diodes, with voltage ratings from 70 V to 1600 V. Featuring advanced high-performance silicon nitride ceramic, as referenced in [1], the ISO247 is specifically engineered to meet the stringent demands of SiC MOSFET-based applications, offering several key advantages over standard TO-247 packages.

- High performance ceramic-based active metal brazing (AMB) substrate offers inherent isolation, higher thermal conductivity and reduced thermal resistance junction-to-heatsink [1].

- Isolation voltage rating of 2.5 kV AC, 1 minute or 3 kV AC, 1 second.

- Higher temperature and power cycling in seconds (PCsec) withstand capability ascribed to the matched co-efficient of thermal expansion (CTE) for SiC chip and AMB substrate [1].

- Increased power density and simplified thermal management.

- Reduced EMI attributed to the small chip-to-heatsink stray capacitance.

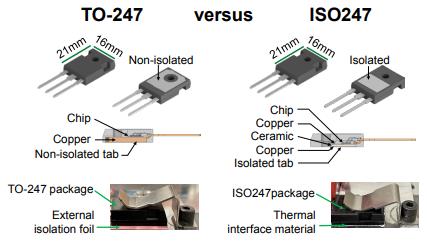

Whilst ISO247 and TO247 packages share identical outer dimensions and pinout configurations, their internal structures and mounting approach have key differentiators as seen in Figure 1: Comparison of internal. While the TO-247 device requires external isolation during its attachment to the heatsink, the ISO247 device employs only thermal interface material for mounting to the heatsink [2]. Note: The thermal interface material provides no electrical isolation, its function is only to improve thermal conductivity.

Thermal Performance Comparison of SiC MOSFETs in ISO247 and TO247 Packages.

The standard TO-247 package features an electrically conductive mounting tab, usually at the drain potential. For safety reasons and to enable multiple discrete devices to share the same heatsink frame, it is typically necessary to electrically isolate the mounting tab from the heatsink.

The utilization of an external, thermally conductive, electrically isolating foil between the semiconductor package and the heatsink has become a widely adopted approach in the industry for this purpose. Nonetheless, employing external isolation entails significant drawbacks. Increased thermal resistance, diminished power and current handling capacity, complex thermal management, and substantial assembly efforts are each either direct or indirect consequences of external isolation tactics. The mentioned penalties, particularly the issue of reduced power handling capabilities, become unacceptable, especially in cases where wide-bandgap (WBG) semiconductors like SiC MOSFETs are utilized.

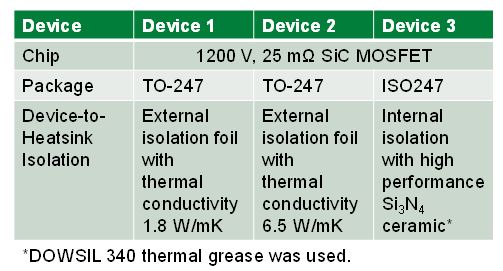

To evaluate the performance advantages of the advanced ISO247 package, thermal measurements were conducted using a 1200 V, 25 mΩ SiC MOSFET chip in various packaging and thermal interface configurations summarized in Table 1. Thermal measurements were executed using the cooling curve method in accordance with IEC 60747-8 [3], with measurement set-up detailed in reference [4, 5].

Thermal measurement results for a heating current IH=40 A are illustrated in Figure 1. As evident from Figure 1a, the ISO247 with high performance ceramic improves the steady state thermal resistance RthJH, by up to 64% when compared to the TO-247 devices. Likewise, as depicted in Figure 1b, the SiC chip in the advanced ISO247 package stays up to 60°C cooler when compared to the TO-247 devices with external isolation. This results in a lower temperature swing between the junction and heatsink, ∆TJH, at the given heating current. The advanced ISO247 has nearly a 53% reduction in temperature swing ∆TJH compared to the standard discrete, significantly improving the device’s lifetime and in turn the reliability of the system.

Enhancing Application Power Output and Lowering System-Level Costs with ISO247

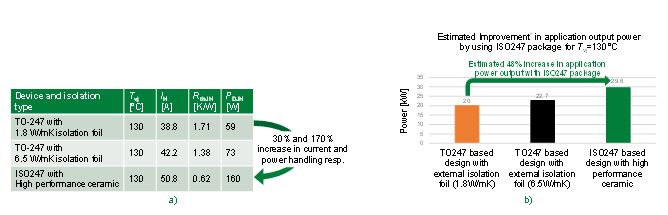

To demonstrate the improvement in application power output using the ISO247, thermal measurements with a heating current IH resulting in a chip temperature Tvj of 130°C were applied to different packages, all containing the same 25 mΩ, SiC MOSFET chip. A junction temperature, Tvj of 130°C was selected, as most real-world applications are designed to operate with chip temperatures Tvj≤130°C. The results from the thermal measurements have been summarized in Figure 3a. It is apparent that the ISO247 package demonstrates a remarkable 170% improvement in power handling capacity and 30% improvement in current handling capacity compared to the TO-247 packages at a junction temperature of 130°C.

The exceptional thermal performance exhibited by the advanced ISO247 package unleashes the potential for enhancing power density and output power in the end application. Upgrading an active front end converter with a DC-link voltage of 800 V originally designed for 20 kW from 1200 V, 25 mΩ, SiC MOSFETs in TO-247 package with external isolation foil to the same SiC MOSFETs in advanced ISO247 packaging solution could potentially increase the DC power output of this system to ~30 kW. This represents a substantial increase in DC power output—up to 48% —as depicted in Figure 3b.

The ISO247 solution additionally offers a considerable opportunity for cost savings. An example scenario is shown in Table 2.

- Direct cost savings attributed to the enhancement in current and power handling capability, improved power density, savings in PCB area, and SiC chip cost.

- Indirect cost savings due to reduction in potential warranty claims by eliminating isolation foil.

Summary

The increasing adoption of WBG devices necessitates innovative packaging advancements to maximize the benefits of WBG semiconductors. The ISO247 from Littelfuse is a unique isolated package specifically designed to address the rigorous requirements of SiC-based applications while remaining compatible with the standard TO-247 footprint. From the thermal measurement comparison, between the ISO247 and TO-247 packages, it has been established that the Littelfuse ISO247 with high performance Si3N4 ceramic offers a remarkable 64% reduction in thermal resistance, RthJH and 53% reduction in temperature swing, ∆TJH. Consequently, the SiC MOSFET chip in the ISO247 package remains up to 60°C cooler at the same DC current, significantly improving overall device lifetime and application reliability. Engineers can choose higher RDS(on) chips for a given application power rating, due to the improved thermal resistance, RthJH and power dissipation, PDJH of the ISO247 package with high performance ceramic.

This offers a substantial cost-saving opportunity at the system level. Furthermore, using the ISO247 in power-electronic applications streamlines mounting, conserves space, lowers overall thermal resistance, enhances power density, and simplifies thermal design.

References

[1] S Shridhar Paradkar, F. Perraud, ‘ISO247: High Performance Ceramic based Advanced Isolated Discrete Package to Fully Exploit the Advantages of SiC MOSFET’; PCIM-2024, Nuremberg, Germany

[2] Application Note: ‘ISOPLUSTM: Isolated Discrete Power Semiconductors’, www.littelfuse.com, access on 29-12-2023.

[3] IEC Standard: ‘IEC 60747-8:Semiconductor Devices – Discrete Devices – Part 8: Field-effect Transistors’, Edition 3.0, 2010-12.

[4] A. Bhatt, U. Kulsoom, F. Perraud, M. Schulz, L. Gant, ‘ISOPLUS – SMPD: An Advanced Isolated Packaging to Fully Exploit the Advantages of SiC MOSFETs’; PCIM-2023, Nuremberg, Germany

[5] A. Bhatt et al., ‘SMPD: An Advanced Isolated Package to Keep the SiC MOSFET Chip up to 75°C Cooler’, Article in Bodo’s Power Systems, pp. 34-35, Jul 2023.