The Importance of Condition Monitoring in Smart Industries

Real-time, continuous, condition monitoring and predictive maintenance solutions continue to grow in importance as manufacturers and plant operators look to increase throughput while reducing maintenance costs and asset downtime. Condition monitoring can extend equipment lifespans, improve manufacturing quality, and increase safety in manufacturing plants.

Given that unscheduled downtime can amount to nearly a quarter of total manu- facturing costs, predictive maintenance has the potential to unlock significant savings and productivity.1

Industry market reports focused on condition monitoring and predictive mainte- nance project compound annual growth rates (CAGR) of 25% to 40%, as driven by two growth areas. The first is the increased deployment of smart sensors to monitor asset health. The second growth area is the increased use of artificial intelligence and advanced analytics to transform asset health data into actionable insights for predictive maintenance and create new service-based, predictive maintenance business model opportunities. Growth in new condition monitoring deployments will range across multiple industries, including:

▶ Waste and wastewater treatment ▶ Manufacturing

▶ Paper and pulp ▶ Food and beverage

▶ Pharmaceutical ▶ Metal and mining

▶ Energy ▶ Oil and gas installations

Within these industries, condition monitoring applications are expanding beyond the traditional rotating equipment applications (pumps, compressors, and fans) to new applications in CNC machines, machine tools, encoders, conveyor belts, robotics, and instruments (see Figure 1).

Existing Communications Challenges

Connectivity from smart sensors to higher level management systems has been one of the key challenges for condition monitoring applications. To date, condition monitoring applications have used wired or wireless connectivity solutions depending on the end application requirements. Wireless connectivity solutions have advantages in terms of ease of deployment but are often limited in terms of bandwidth and/or battery life. Wired connectivity solutions are sometimes limited in data bandwidth, and long distances in harsh industrial environments are not always supported and often require a separate cable for power.

Existing Industrial Ethernet solutions based on 100BASE-TX/10BASE-T provide high data bandwidth up to 100 Mb and power over a Cat-5 or Cat-6e cable with PoE but are limited to 100 m distance and don’t support hazardous area use cases as they are high power solutions. Condition monitoring applications require support for potentially remote sensors that require robust communication over a long distance where the sensor node is in a space and power constrained IP66/IP67 enclosure due to the harsh industrial environment it is deployed in. These constrained sensor node applications need a low power, high data bandwidth communications solution that delivers both power and data on a low cost, easy to install cable with a small cable connector to the sensor node.

New Connectivity Solutions with Single Pair Ethernet

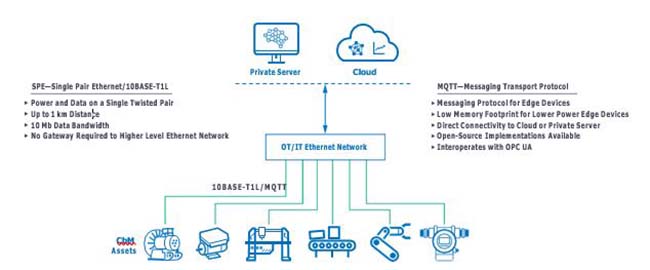

New single pair Ethernet (SPE) physical layer standards developed by the IEEE are offering new connectivity solutions for communicating asset health insights for condition monitoring applications. 10BASE-T1L is a new Ethernet physical layer standard (IEEE 802.3cg-2019) that was approved by the IEEE on November 7, 2019. It will dramatically change the automation industry by significantly improving operational efficiency through seamless Ethernet connectivity to field-level assets. 10BASE-T1L solves the challenges that, to date, have limited the use of Ethernet to the field assets. These challenges include power, bandwidth, cabling, distance, data islands, and Intrinsically Safe Zone 0 (hazardous areas) applica- tions. By solving these challenges for both brownfield upgrades and new greenfield installations, 10BASE-T1L will enable new asset health insights that were previously unavailable and seamlessly communicate them to the control layer and to the cloud/private server. These new insights will awaken new possibilities for data analysis, operational insights, and productivity improvements through a converged Ethernet network from the field assets to the cloud or private server (see Figure 2).

Advantages of 10BASE-T1L Ethernet Connectivity

10BASE-T1L removes the need for complex, power hungry gateways required by legacy communications to connect to the control and management network and enables a converged Ethernet network across the information technology (IT) and operating technology (OT) networks. This converged network delivers a simplified installation, easy device replacement, and faster network commissioning and configuration. This results in faster software updates with simplified root cause analysis and maintenance of field-level assets. The 10BASE-T1L physical layer combined with messaging transport protocol (MQTT) provides a messaging protocol for field assets with a low memory footprint for lower power smart sensors. MQTT provides direct connectivity of asset health insights to the cloud or a private server for advanced data analytics for predictive maintenance techniques.

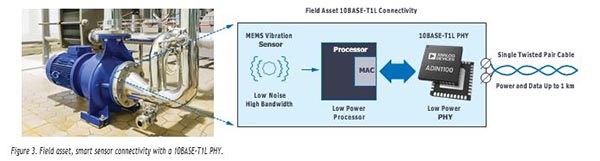

To communicate with a 10BASE-T1L enabled field asset, a host processor with integrated medium access control (MAC), a passive media converter, or a switch with 10BASE-T1L ports is required. Additional software, special drivers, or customized TCP/IP stacks are not required (see Figure 3). This results in clear advantages for 10BASE-T1L devices:

▶ 10BASE-T1L is a very low power physical layer technology that can enable very low power smart sensor deployments with a high data bandwidth connectivity solution. A smart sensor connected with 10BASE-T1L is accessible over the network and can be remotely updated anywhere, at any time. As sensors become more complex, the probability of software updates increases. Updates are now possible within realistic periods of time via a fast Ethernet connection.

▶ Access to advanced Ethernet network diagnostic tools to simplify root cause analysis.

▶ Increased smart sensor installation flexibility via a single twisted pair cable up to 1 km and beyond, with power and data on a single twisted pair cable.

▶ Asset health insights are now available remotely, via a web server running on the field asset, reducing the need for a maintenance technician to walk the floor to monitor an asset’s health—a significant cost saver.

10BASE-T1L, Power and Data on Two Wires

ADI’s portfolio of 10BASE-T1L PHY (ADIN1100) and unique MAC PHY (ADIN1110) enables lower power Ethernet connectivity on a single twisted pair cable that’s over 1700 m with only 39 mW and 43 mW of power consumption respectively. Single-pair Power over Ethernet (SPoE) or engineered power solutions are combined with a 10BASE-T1L PHY or MAC PHY to provide both power and data over a single twisted pair cable. A 10 Mb data bandwidth communication link with significant power capability over the same cable allows smart sensors with the power and connectivity bandwidth to support new condition monitoring applications. The ADIN1110 facilitates the industry’s lowest power system design, which simplifies adding Ethernet to sensors and reduces the burden on the processor technology, removing the need for an integrated MAC. ADI’s unique MAC PHY technology provides an SPI interface to ultra low power processors to imple- ment lower overall system power consumption, which is of critical important for sensor nodes. With 10BASE-T1L connectivity, asset health insights are now more accessible as the insights are available across a converged IT/OT Ethernet network. 10BASE-T1L supports hazardous area use case applications (Intrinsically Safe Zone 0) for process automation deployments and is sometimes referred to as Ethernet-APL. 10BASE-T1L/Ethernet-APL will enable new lower power solutions to connect asset health monitoring smart sensors to the higher level data management systems. This will empower AI and advanced analytic systems to transform asset health data into actionable insights and deploy new predictive maintenance services.

System-Level Solutions and AI Platforms to Accelerate Condition Monitoring Deployments

Complete, system-level solutions for condition monitoring applications will be key to enabling higher quality data and insights, thereby significantly improving manufacturing processes. Advances in 10BASE-T1L/Ethernet-APL, coupled with a real-time, AI-driven sensing technology such as ADI OtoSense™, can enable AI integration at all levels of customer systems. The ADI OtoSense platform senses and interprets any sound, vibration, pressure, current, or temperature to provide continuous, condition-based monitoring and on-demand diagnostics. It operates on the field asset at the edge, in real time, both online and offline. The ADI OtoSense system detects anomalies and learns from interaction with condition monitoring domain experts while creating a digital fingerprint to help identify faults in a machine so it can predict breakdowns before they cause costly downtime, damage, or catastrophic failure.

Advancements in sensing, signal processing, connectivity, mechanical packaging techniques, and artificial intelligence at the edge are enabling new condition monitoring solutions and predictive maintenance services that will unlock significant savings and productivity improvements.

New system-level solutions for condition monitoring applications will include MEMS sensors for vibration and shock detection, precision converter technologies for data acquisition, and edge processing to create high quality asset health data. Low power, robust wired and wireless communication solutions provide access to the asset health data from the asset. Wireless communication solutions include SmartMesh® or Wireless HART®. Wired communications solutions include RS-485 or 10BASE-T1L single pair Ethernet that provides power and data on two wires. These technologies along with high performance power management are combined in asset monitoring solutions (such as OtoSense technology), which are complete hardware and AI monitoring solutions that can be mounted on equipment for predictive maintenance (see Figure 4).

Higher quality asset health insights and faster connectivity will extend equipment lifespans, reduce maintenance costs, and eliminate unscheduled downtime while maintaining the highest levels of manufacturing quality and safety in smart factories.

To learn more about complete, system-level solutions and artificial intelligence offerings for condition monitoring applications and how ADI can help customers and partners quickly develop and deploy an end-to-end monitoring and predictive maintenance service-based solution, please visit analog.com/cbm.

References

1 “The Costs and Benefits of Advanced Maintenance in Manufacturing.” U.S. Department of Commerce, April 2018.

About the Author

Maurice O’Brien is the strategic marketing manager for industrial automation at Analog Devices. He is responsible for delivering industrial automation focused, system-level solutions. Prior to this role, Maurice spent 3 years working on Industrial Ethernet and 15 years working in applications and marketing roles in power management with Analog Devices. He has a B.Eng. in electronic engineering from the University of Limerick, Ireland. He can be reached at maurice.obrien@analog.com.