Summary: When using flexible PCBs in electric vehicle battery management systems, mechanical stress and temperature changes from laser soldering can lead to thermal cracking of surface-mount NTC thermistors — a potentially catastrophic failure that’s difficult to detect. The threat of component cracking can be minimized by utilizing bulk metal oxide thermistors with flexible terminations.

As the electric vehicle (EV) market continues its rapid growth, so too do technical challenges and the innovations developed to address them. Of these, design engineers are most heavily focused on improving battery technology, power circuit efficiency, and fast charging solutions.

Currently the dominant battery chemistry used in EVs is lithium-ion, with single cell voltages of 3.6 V to 3.7 V. Creating a power system with an overall voltage of 500 V to 900 V can therefore require up to a few hundred of these cells in a serial-parallel set-up. Furthermore, optimizing the performance for a system involving this many cells requires an efficient battery management system (BMS), which must monitor temperature, impedance (internal cell resistance), the voltage, and the charge and discharge current. Each of these specifications impacts battery performance.

A BMS consists of a cell management controller (CMC) and the master central unit — or the battery management controller (BMC). CMCs use multichannel ICs (currently equipped with up to 16 channels) to perform the monitoring function, while the BMC handles the control function of the individual CMCs. Core parameters being measured in this type of system are temperature, impedance, voltage, and current.

When specifically looking at temperature measurement, negative temperature coefficient (NTC) thermistors are the most common component solution. Typically, the devices are attached very close to the cell or module walls, or to electrical connections, to identify “hot spots.” As the thermistor temperature rises, the electrical resistance decreases with a high sensitivity curve due to the component’s large negative temperature coefficient of resistance. The temperature is determined by measuring a voltage in a resistor-thermistor network by means of an integrated analog / digital converter (ADC) in the IC. Accurate temperature readings are very important to the proper functionality of the battery and the safety of the system. For precise temperature measurement, the NTC and the measuring circuit resistances are very important.

High voltage battery systems can consist of twenty or more surface-mount NTC thermistors positioned on a flex circuit that is wrapped around the assembled battery structure. If the mounting substrate is an FR4 PCB, these components could be reflow or wave soldered. However, some flex circuits cannot use these soldering techniques, and instead rely on laser soldering with local heating to avoid damage to other sensitive parts. If this process is not tightly controlled, it can lead to thermal cracking of the ceramic components. Similarly, the whole battery system can experience significant mechanical stress in both assembly and operation. Here again, the flex circuit assembly can be exposed to torsional stress via component terminations, or even direct pressure on the component itself that results in cracking.

This type of failure is dependent on several factors, which can make it difficult to detect and less likely to predictably occur. In addition, as has been well documented for multilayer ceramic capacitors, the actual component failure (component cracking) may not appear until much later — well after the system has been deployed. This type of failure is also potentially catastrophic, which makes replacement / repair very costly.

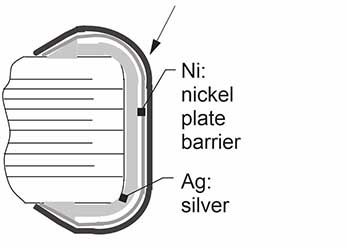

To mitigate the risk of component cracking due to temperature changes, or the mechanical stress potentially seen when using flexible PCBs, Vishay NTCS series of thermistors employs a bulk metal oxide material with a polymer termination of cured epoxy, electroplated with nickel-tin, rather than a fired thick film material. This solution provides a flexible termination structure that significantly outperforms alternative termination materials during stress tests, in addition to other manufacturers’ flexible termination solutions seen on multi-layer structured ceramic components.

As the stresses on battery management assemblies using flexible PCB circuits may vary from one assembly to another, employing flexible termination solutions that can absorb torsional force and thermal stress can significantly reduce the potential for field failures, and therefore improve reliability and useful life.