The use of cyanoacrylates requires a high level of process know-how and optimum metering technology. Otherwise, a lot of expensive rejects are produced in a very short time with 1K second adhesives. With non-contact jetting processes, many practical problems can be easily tackled.

Why use cyanoacrylates?

In many industries, shorter and shorter cycle times are required. In the case of bonding, the question of curing often arises, i.e. when parts can be further processed reliably after joining. This is largely determined by the adhesives used and the process technology employed. Cyanoacrylates have the advantage that they cure extremely quickly at room temperature. Short cycle times are therefore no problem, but they need to be mastered in the process. In addition, many applications place high demands on the quality of a bond. In medical technology, for example, membranes or other components have to be bonded to plastic parts. The challenge is that the adhesive not only bonds the two parts, but that this bond also remains tight under higher pressure. The choice of adhesive and its optimal application are the central prerequisites for this. In many cases, cyanoacrylates are processed by contact with a peristaltic pump, which can lead to various problems in practice.

The solution – dispensing with jet valves

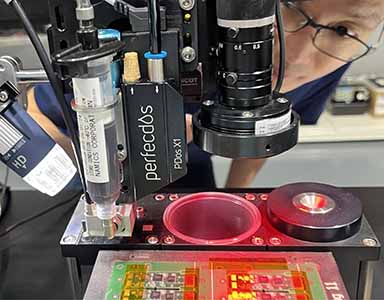

With the PDos X1, the cyanoacrylate is applied contact-free in individual droplets at a very high frequency, thus creating a sealing bead. The droplets can be between 250 μm and 2.5 mm in size. The adhesives are dispensed with a repeat accuracy of 99% in relation to the dispensing volume. With the jet valve, dispensing can be done freely in space. This opens up new degrees of freedom in component design and allows simpler and thus more cost-effective machine designs. In addition, the usual defects and impurities caused by deviating adhesive quantities are virtually eliminated with this process. This improves component quality and minimises rejects. The fully automatic and stable dispensing process on which this method is based also contributes to this.

The perfecdos dosing valves are – mechanically speaking – designed as a “normally closed“ system (NC). Care was taken in the design to ensure that leakage is reliably prevented in the event of a failure of the supply media. When dispensing cyanoacrylates, particular attention must be paid to their reaction time. Material selection and design of the precision valves are optimised to avoid a fast reaction of the material in the valve, which would lead to clogging. In addition, the quick and easy cleaning of the valves contributes to the realisation of effective cyanoacrylate jetting processes. In practice, dispensing from cartridges has proven successful for these adhesives. Ideally, one cartridge is sufficient for one coat, which also simplifies cleaning routines. Cartridges are available with volumes up to 950 ml.

The modular design of the valve also allows easy adaptation to the respective tasks – regardless of whether it is a simple retrofit in existing systems, e.g. as a replacement for a contact metering solution, or new systems.

The precise contactless dispensing of cyanoacrylates with the PDos X1 jet valve is a concept that pays off, because highly accurate contactless dispensing applies the reactive adhesives where they are needed. This saves a lot of money while increasing product quality. From a total cost of ownership perspective, 300 cycles/s, which enable faster production with minimised waste, are key aspects. Simpler machine design and process monitoring also save a lot of money.

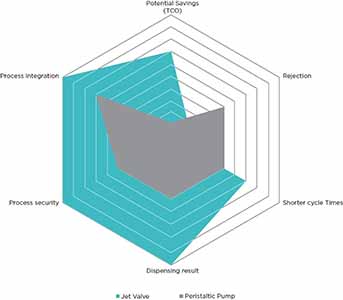

So there are many aspects in favour of this concept. Figure 1 shows the potential of the jet valve compared to the peristaltic pump. The values are based on practical experience. While dosing by peristaltic pump comes close to contactless dosing in terms of process integration and safety as well as dosing results, the jet technology offers considerable potential in terms of savings, high product quality, minimised rejects and shorter production times.

What makes cyanoacrylates so interesting?

Sometimes also called instant adhesives, these moisture-curing adhesives have a high adhesive strength and extremely fast curing time. Parts to be joined can normally be processed immediately. As with all other 1C adhesives, there is no need for additional mixing here. They are low viscosity and therefore very economical and easy to dispense. Cyanoacrylates can be used with a wide range of materials. No additional energy in the form of heat or pressure needs to be applied in the process. They are interesting from an ecological point of view because they are solvent-free. They can be stored without problems and transported worldwide without restrictions. Because they are solvent-free, they are not hazardous goods in the sense of transport regulations.

The PDos X1 Jetting Valve has been successfully incorporated into TechnoDigm™ Automated Fluid Dispensing Systems, marking a significant achievement. TechnoDigm™ is known for its expertise in handling a wide range of materials and able to provide solutions tailored to your exact needs. Additionally, the PDos X1 Jetting Valve seamlessly integrates into TechnoDigm™ IDS2000 Automated Fluid Dispensing System, ensuring precise and repeatable dispensing.

Contact perfecdos c/o Technodigm; info@techno-digm.com; +65 6493 3826