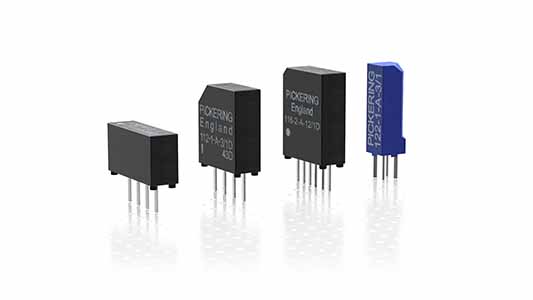

Leading manufacturer of high performance reed relays, Pickering Electronics has increased the power ratings of four of its most popular relay series – including Series 112, 113 and 116, plus ultra-high density 4mm2 Series 122 – to ensure engineers have more options for higher switching specifications, without taking up more valuable PCB space. As part of the company’s ongoing commitment of continuous innovation and product improvement, the higher power ratings enhance the already wide range of switching options available. With thousands of versions on offer, as well as customisable options and bespoke relays to fit any application need, engineers have more flexibility than ever before.

Series 112

The Series 112 single-in-line (SIL) reed relays, requiring a board area of only 0.15 inches (3.8mm) by 0.4 inches (10mm), now feature a new general purpose switch type 1 option, rated for up to 20 Watts (15 W for the 3 V coil version) at 1 Amp switching current (with 1 Amp carry current). The small footprint in this relay is achieved by mounting the reed switch diagonally within the package. The Series is suitable for high-density card-based systems such as VME, VXI, CompactPCI, and PXI. The high-quality, sputtered ruthenium switch contacts also make them ideal for ATE (automatic test equipment).

Series 113

The Series 113 SIL reed relay range has also been updated to include the new general purpose switch type 1 options. This switch is rated for up to 20 Watts (15 W for the 3 V coil version) at 1 Amp switching current, with 1 Amp carry current. The board area remains compact at 0.15 inches (3.8mm) by 0.5 inches (12.7mm). This series also includes the smallest changeover reed relay available on the market, with a 2 Watts rating (switch type number 3) and a coaxial device suitable for up to 3GHz. Additionally, the switch type 1 option will be available in 2-pole DPST with a 5 V coil, offering up to 20 Watts switching at 1 Amp.

Series 116

Designed for very high-density applications, such as ATE switching matrices or multiplexers, the Series 116 relays now offer new general purpose switch type 1 options rated for up to 20 Watts (15 W for the 3 V and 5 V coil versions) at 1 Amp switching current, with 1 Amp carry current. The board area is optimized with 1 Form A (SPST) stacking on a 0.15 inch (3.8mm) x 0.27 inch (6.9mm) pitch and 2 Form A (DPST) stacking on a 0.15 inch (3.8mm) x 0.40 inch (10mm) pitch. Series 116 will also be available in 2-pole DPST, with a 5 V coil up to 1 Amp, 15 W, or a 12 V coil with up to 20 W switching.

Ultra-High Density Series 122

The Series 122 reed relays, which occupy a PCB footprint of only 4mm x 4mm, now feature new general purpose switch type 1 options rated for up to 15 Watts at 1 Amp switching current, with 1 Amp carry current. Measuring 12.5mm in height, these relays facilitate the highest packing density currently available and feature the highest quality instrumentation grade reed switches and internal mu-metal magnetic screens to minimize magnetic interaction when relays are stacked closely together.

“With these increased power ratings for new general purpose switch type number 1 options – 50-100% higher than in previous switch type number 2 option,” noted Kevin Mallett, Technical Specialist at Pickering Electronics, “customers can now benefit from higher switching specification options across four of our most popular relay series.”

Pickering reed relays are known for their reliability due to superior manufacturing and quality control processes. They feature instrumentation-grade sputtered ruthenium contacts, rather than the more common electroplated rhodium associated with low grade reed relays with less stable contact resistance. Along with Pickering’s formerless coil construction, this maximises magnetic efficiency, allowing the use of less sensitive reed switches resulting in optimal switching action and extended lifetime at operational extremes. Magnetic mu-metal screening eliminates problems that would otherwise be experienced due to magnetic interaction when relays are closely stacked. Pickering also stands out by 100% testing all operating parameters, including dynamic contact wave-shape analysis with thorough data scrutiny to ensure consistency. Unlike other manufacturers that perform only simple DC testing or batch testing, which can lead to non-operational devices being supplied, Pickering Electronics guarantees reliability. Additionally, they conduct 100% thermal cycling stress testing of the manufacturing processes, ranging from -20°C to +85°C and back to -20°C, repeated three times. This rigorous testing is rarely performed by other manufacturers, often resulting in repeated field failures.