Electric car sales have grown in 2021 and have remained strong so far in 2022, with the global electric vehicle market size projected to reach 39,208 thousand units by 2030. It is estimated that the market will witness a growth rate of up to 21.7% until 2030.

The electric vehicle segment actually includes several different types, from electric cars and electric scooters to electric buses and trucks. However, the passenger vehicle segment is expected to be the largest market in the electric vehicle segment. This translates to more stringent requirements for EV electric circuits.

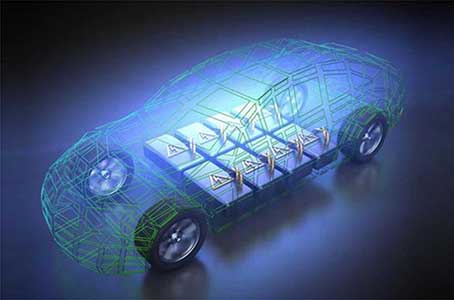

One of the most important systems within automotive applications involves the battery management systems (BMS) found in EVs.

Below we will review in more detail some key points to consider in relation to power supplies for EVs.

Introduction of BMS

Electric vehicles heavily rely on effective battery management systems (BMS), which involve circuits that are responsible for monitoring both the charging and discharging of batteries. BMSs also enable communication with other vehicular systems, among many other responsibilities:

- Controlling the battery based on its primary and secondary data

- Balancing the battery system

- Monitoring the state of the battery (including its state of function, state of charge, state of capacity, and other factors)

- Preventing the battery from operating outside of its safety requirements

- Calculating secondary data in relation to the monitoring and control of the battery

The BMS is essential to ensure high reliability, longevity, and protection of the EV battery supply. In case of failure of the BMS of an EV, the consequences will be serious: the vehicle, its passengers, and even those nearby will all be in danger.

The power supply of an EV depends greatly on the intelligent charging device, which must integrate seamlessly with the BMS. The power supply should also provide current to systems that are critical to ensure the safety of the vehicle and any individuals involved. Some of these systems include the electronic accelerator, the tire pressure detecting system, the control and driving system, and the CAN communication system. The operation of the vehicle itself relies on the ECS (the engine control system), the car meter panel, and the motor voltage monitoring system.

The requirements of power supply in BMS

In terms of power supplies, there are several considerations engineers should make when designing the electric circuit of an EV and its BMS:

- High reliability

- High efficiency

- Meets the IATF16949 system requirements

- AEC-Q100 approved

- High protection against several potential problems (such as short circuits)

- High isolation voltage

- High compatibility with standard current and voltage requirements

- An operating temperature range in accordance with automotive applications

- Compact design that is compatible with standard pin-outs

MORNSUN’s Power Supply Solutions

The cost-effective, compact, and reliable power solutions have become the primary focus for electric vehicles. The safety and high reliability of EV electric circuits should be at the forefront of their design.

As a one-stop power solution provider, MORNSUN can provide a series of products that are specifically designed for EV applications. In particular, DC/DC converters are among some of the most critical circuitry components involved in a standard BMS for an EV. MORNSUN owns a series of DC/DC converters that are ideal for intelligent automotive applications, including those involving the BMS.

Specifically, MORNSUN can provide AEC-Q100 approved DC/DC converters with an operating temperature range spacing from -40℃ to +105 ℃. The MORNSUN CUWF24_J(Y)T-3WR3/6WR3 converters feature an ultra-wide input voltage range of 6-42VDC, an outstanding EMI performance that meets the automotive standards EN55025/CISPR 25 standard class 4. Another DC/DC converters worth considering is the CF0505XT-1WR3, which meets the IATF16949 system requirements and provides continuous self-recovery short-circuit protection. It features a 3500VDC isolation voltage and operates efficiency up to of 82%. The DC/DC converter is compact with an internal SMD design and an international standard pin-out.

Those DC/DC converters we have just introduced can withstand the harsh conditions of automotive applications while guaranteeing high safety and long-term reliability. Click here to request more information about our power supply solutions for EV applications.

For more information, please visit www.mornsun-power.com