Industries globally are increasingly prioritizing automation, safety, and real-time process control. As such, the role of pressure transmitters has evolved from a simple sensor to a critical component of smart industrial infrastructure. These devices enable accurate monitoring, diagnostics, and control by measuring pressure and converting it into a standardized output signal. From oil refineries and wastewater plants to food processing lines and pharmaceutical cleanrooms, pressure transmitters are embedded across a wide range of applications. Let’s delve into the current state of the pressure transmitter market and the key factors influencing its growth trajectory.

What Are Pressure Transmitters?

Pressure transmitters are precision instruments used to measure the pressure of gases, liquids, or steam in industrial systems and convert that measurement into a standardized electrical signal for monitoring, control, or automation purposes. Unlike simple pressure gauges, transmitters provide continuous, real-time data to centralized systems. They consist of a pressure sensor, a signal processing unit, and an output interface. Pressure transmitters play a crucial role in maintaining process stability, safety, and efficiency in various sectors, including oil and gas, chemicals, water treatment, power generation, and pharmaceuticals.

What Are Key Report Highlights?

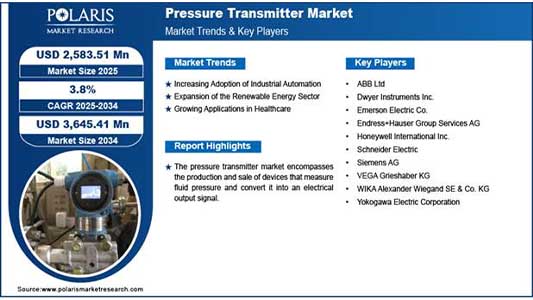

- The latest analysis by Polaris Market Research reveals that the pressure transmitter market stood at USD 2,492.53 million in 2024.

- With a CAGR of 3.8% from 2025 to 2034, the market is projected to grow to USD 3,645.41 million by 2034.

- The report highlights that pressure transmitters are expected to be increasingly adopted level measurement, owing to the growing demand for precise liquid level monitoring and control in industries like pharmaceuticals and wastewater treatment.

- The study notes that Asia Pacific is expected to witness increased usage of pressure transmitters, driven by the rapid industrial growth across key economies such as India, China, and Southeast Asia.

What Are Commonly Used Pressure Transmitter Types?

Here’s a detailed explanation of some of the most widely used types of pressure transmitters:

Differential Pressure Transmitters

Differential pressure transmitters measure the pressure difference between two points in a system. These transmitters have two ports: a high-pressure port and a low-pressure port. They calculate the difference in pressure between these ports to provide insights. Differential pressure transmitters are commonly used in conjunction with flow elements such as orifice plates and venturi tubes. They are integral to fluid dynamics and energy management across various industries, including oil and gas, HVAC, and water treatment.

Absolute Pressure Transmitters

Absolute pressure transmitters measure pressure in reference to a perfect vacuum. That way, they provide readings that are unaffected by changes in atmospheric pressure. These instruments are ideal for applications that require precise and stable measurements, regardless of altitude or weather conditions. Absolute pressure transmitters are utilized in vacuum systems, aerospace simulations, and semiconductor manufacturing processes.

Gauge Pressure Transmitters

Gauge pressure transmitters are the most widely used type in industrial and commercial settings. They provide measurements relative to the surrounding atmospheric pressure. The sensor in these transmitters compares the process pressure to ambient pressure, making them suitable for pipelines, hydraulics, compressors, and tank pressure monitoring. Their simplicity and practical alignment with real-world conditions contribute to their widespread adoption.

View More Information @ https://www.polarismarketresearch.com/industry-analysis/pressure-transmitter-market/request-for-sample

What’s Propelling Market Forward?

Here’s a look at the key factors shaping the pressure transmitter market landscape:

Industrial Automation and Process Optimization

The rising emphasis on automation across industries to streamline operations and reduce human error has made pressure transmitters indispensable. These devices offer continuous, real-time data about pressure levels in pipelines, vessels, and processing systems. In sectors such as oil and gas, chemicals, and heavy manufacturing, this data enables predictive maintenance, efficient process control, and enhanced safety. Pressure transmitters directly contribute to operational efficiency and cost savings by preventing equipment failure and optimizing energy use.

Environmental Regulations and Safety Mandates

Governments and regulatory bodies worldwide are implementing stricter environmental and safety regulations across sectors that handle volatile or hazardous materials. Pressure transmitters play a crucial role in early leak detection, pressure surge management, and environmental containment. In explosive or corrosive environments, such as refineries, chemical plants, and power stations, specialized pressure transmitters help companies maintain compliance while minimizing risks to personnel and assets.

Technology Insights and Product Trends

Here’s a look at the key trends and technologies that are shaping the market landscape:

Energy Efficiency and Power Management: Battery-powered and energy-harvesting pressure transmitters are being introduced for remote and offshore operations. Their use reduces the need for continuous external power and wiring infrastructure.

Wireless and IIoT Integration: WirelessHART and LoRaWAN-based transmitters are gaining traction in industries where hardwiring is difficult or expensive. These transmitters enable cost-effective, scalable sensor networks for real-time visibility across distributed assets.

Advanced Materials and Miniaturization: Next-generation transmitters are incorporating corrosion-resistant alloys, ceramic diaphragms, and MEMS (Micro-Electro-Mechanical Systems) to enhance durability, minimize footprint, and reduce overall lifecycle costs.

Conclusion

The pressure transmitter market stands at the intersection of precision engineering and digital innovation. As industries adapt to a data-driven, safety-conscious world, these devices are fundamental to modern infrastructure. Whether it’s enabling smart grid operations or maintaining pharmaceutical purity, pressure transmitters are becoming smarter, smaller, and more indispensable.