The field of medical electronics is rapidly evolving, integrating cutting-edge technologies to enhance the efficiency and reliability of healthcare devices. From diagnostic equipment to implantable devices and wearable sensors, simulation tools like ANSYS play a pivotal role in driving innovation and ensuring safety and performance in these critical applications. This article explores how ANSYS simulation tools empower engineers and researchers to design, analyze, and optimize medical electronics with unparalleled accuracy and effectiveness.

1. Why Simulation is a Game-Changer in Medical Electronics?

Medical electronics demand high precision, reliability, and compliance with stringent regulatory standards. The complexity of these devices often requires engineers to address challenges such as miniaturization, thermal management, electromagnetic interference (EMI), and patient safety. Simulation tools like ANSYS provide a strategic edge with CADFEM’s expertise in delivering ANSYS solutions by:

- Organizations can streamline their simulation workflows, enhance productivity, and achieve first-time-right designs tailored to the unique demands of medical electronics.

- Accelerating development cycles and cutting down costs by reducing dependency on physical prototyping.

- Predicting device performance across various real-world scenarios with unmatched accuracy.

- Enabling optimization of designs for energy efficiency, longevity, and patient safety.

- Assisting in adhering to global regulatory standards, such as IEC 60601 for medical electrical equipment.

2. Transformative Applications of ANSYS in Medical Electronics

2.1 Implantable Devices

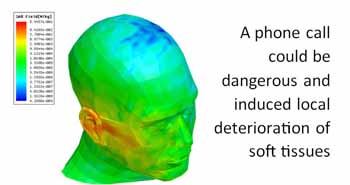

Implantable devices such as pacemakers, cochlear implants, and neurostimulators must operate reliably within the body’s intricate and sensitive environment. ANSYS tools excel in this domain by offering:

- Electromagnetic Simulations: Accurate modeling of electromagnetic fields to ensure seamless functionality without adversely affecting surrounding tissues.

- Thermal Analysis: Heat management studies to avoid tissue damage and maintain device reliability.

- Structural Analysis: Ensuring the mechanical durability of devices against physiological stresses.

Example: ANSYS Maxwell has been instrumental in fine-tuning the electromagnetic compatibility of pacemakers, balancing performance and patient safety.

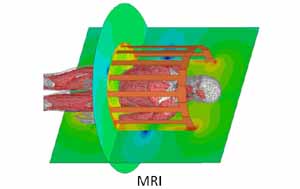

2.2 Diagnostic Equipment

Devices like MRI scanners, ultrasound machines, and X-ray systems demand exacting standards in design and functionality. ANSYS tools contribute by:

- Enhancing Electromagnetic Compatibility (EMC): Ensuring devices can coexist without causing interference.

- Image Optimization: Simulating wave propagation to maximize signal clarity in imaging systems.

- Thermal and Mechanical Safety: Preventing overheating during prolonged diagnostic procedures.

Example: ANSYS HFSS aids in designing MRI coils with precise magnetic field configurations, improving imaging performance and patient comfort.

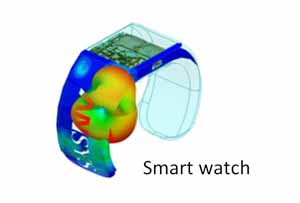

2.3 Wearable Health Monitors

Wearable devices such as fitness trackers and glucose monitors are at the forefront of personalized healthcare. ANSYS supports their development by:

- Antenna Optimization: Ensuring reliable wireless communication for real-time data sharing.

- Power Consumption Analysis: Improving battery life for extended use.

- Thermal Comfort: Evaluating heat dissipation to prevent user discomfort.

Example: ANSYS Icepak ensures thermal safety for long-term wearable device usage, aligning comfort with performance.

3. Advanced Simulation Workflows for Medical Electronics

3.1 Multiphysics Simulations

Medical devices often involve the interplay of electrical, thermal, mechanical, and fluidic factors. Partnering with CADFEM enables engineers to leverage ANSYS’s multiphysics capabilities with industry-specific guidance and support, ensuring robust designs for medical applications like:

- Integrate electromagnetic and thermal analyses for implantable devices.

- Model fluid dynamics for precision in drug delivery systems and ventilators.

- Optimize designs with holistic insights into multiple physical phenomena.

Example: Comprehensive simulations for insulin pumps ensure accurate and reliable performance under diverse conditions.

3.2 PCB Design Excellence

Printed circuit boards (PCBs) form the backbone of medical electronics. ANSYS tools empower engineers to:

- Ensure Signal Integrity (SI): Guarantee high-speed data transmission with minimal losses.

- Optimize Power Integrity (PI): Maintain stable power delivery across devices.

- Manage Thermal Loads: Simulate heat flow in compact and densely populated PCBs.

Example: ANSYS SIwave allows seamless co-simulation of power and thermal dynamics, ensuring reliability in medical-grade PCBs.

3.3 EMI/EMC Compliance

Compliance with EMI and EMC standards is critical for medical devices. ANSYS tools offer:

- Early identification and resolution of interference issues.

- Design optimization for shielding and grounding techniques.

- Validation against standards like FDA and IEC 60601 regulations.

Example: ANSYS HFSS provides actionable insights for mitigating EMI risks in implantable devices, expediting regulatory approvals.

4. Case Study: Redefining Performance in Medical Imaging

A prominent ultrasound manufacturer faced challenges in optimizing the transducer array for enhanced imaging performance and patient safety. Through ANSYS simulations, they achieved:

- Improved electromagnetic wave propagation for sharper imaging.

- Effective thermal management to prevent overheating.

- Enhanced structural durability to withstand rigorous usage.

Impact:

- Achieved 20% improvement in image quality.

- Reduced overheating incidents by 30%.

- Accelerated time-to-market with robust simulation-driven documentation.

5. Future Horizons: Simulation in Next-Generation Medical Electronics

The future of medical electronics is poised for revolutionary advancements, and ANSYS tools are at the core of these innovations. Emerging trends include:

- AI-Powered Simulations: Integrating artificial intelligence for predictive modeling and intelligent optimization.

- Digital Twins: Real-time device monitoring through virtual replicas for predictive maintenance.

- Wearable Biosensors: Designing advanced, energy-efficient sensors for continuous health monitoring.

- 5G Healthcare Devices: Enabling seamless connectivity with advanced antenna and communication designs.

6. Conclusion: Pioneering Healthcare Innovations with ANSYS

With CADFEM’s support and ANSYS simulation tools, the medical electronics industry can confidently address design challenges, accelerate innovation, and achieve groundbreaking advancements in patient care. By fostering precision, efficiency, and compliance, ANSYS empowers the medical industry to pioneer groundbreaking advancements, ultimately improving patient outcomes and elevating the global standard of healthcare.

About The Author:

Satish is a Technology Specialist in Electronics and Semiconductors at CADFEM India, a leading provider of simulation-based engineering solutions. With a focus on delivering cutting-edge expertise in simulation-driven design, Satish specializes in providing electronic systems and semiconductor technologies across diverse industries.

At CADFEM India, an Elite Channel Partner of Ansys in engineering innovation, the emphasis lies on empowering businesses through simulation technology. From electronics and semiconductors to fluid mechanics and structural analysis, CADFEM India delivers solutions that enable faster product development, enhanced performance, and cost optimization. For enquiries contact marketing@cadfem.in, 9849998435.