WASHINGTON, MO ― Sasinno Americas is pleased to introduce its latest advancement in soldering technology – the iBot-i1/2s. This cutting-edge system redefines precision soldering with groundbreaking features designed to elevate efficiency and performance in electronics manufacturing processes. The system will be on display for the first time during the 2024 IPC APEX EXPO.

Key Competitive Edges:

PC Control for Enhanced Precision: The iBot-i1/2s sets a new standard with its PC-based control system, offering superior accuracy and an intuitive user interface compared to traditional teaching pad-based controls.

Advanced Camera Integration: Setting itself apart from competitors, the iBot series integrates advanced cameras for both programming and fiducial checking, ensuring accuracy and efficiency.

Superior Drive Mechanism: Utilizing servo motors and ball screws, the iBot-i1/2s delivers unmatched precision and reliability, eliminating the need for regular tension adjustments common with timing belt-driven stepper motors.

High-Performance JBC Solder Stations: Featuring original JBC solder stations, the iBot-i1/2s offers exceptional heat recovery and durability, guaranteeing seamless soldering experiences.

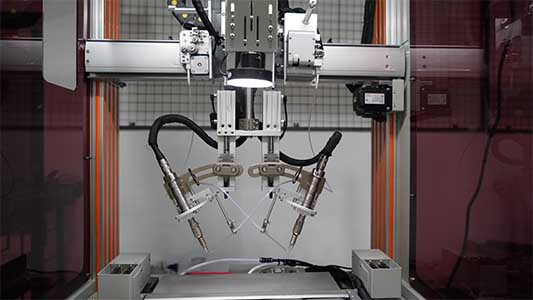

A Leader in Dual-Tip Soldering

The iBot-i1/2s addresses a common challenge in electronics manufacturing by offering dual-tip soldering capabilities on a single table. With distinct solder irons featuring different tip models, this innovative solution streamlines the soldering process without compromising precision, eliminating the need for multiple machines and reducing costs.

As the demand for versatility in soldering processes continues to grow, the iBot-i1/2s is tailored to the complexity of modern PCB designs. With joints varying in size and thermal requirements, this advanced system adapts seamlessly to diverse manufacturing needs.

Visit Booth 4027 at IPC APEX EXPO 2024 to experience firsthand the future of soldering technology.

For more information about SASInno Americas, visit www.sasinnoamericas.com.