Abstract

Analog Devices’ precision signal chain μModule® solutions provide system designers with a compact, highly customizable, integrated solution that simplifies design, enhances performance, and saves valuable development time.1 This approach offers a great advantage to customers who can get to market faster with state-of-the-art performance.

Introduction

With the rapid advances in very large-scale integrated (VLSI) circuit technology arose the multifaceted discipline of signal processing applications, which range from telecommunications and audio systems to industrial automation and automotive electronics. To support these applications, significant research was needed to develop a high performance, discrete linear, and precise signal chain block. This article will illustrate how ADI’s precision signal chain μModule solution is leveraging heterogeneous integration via system-in-package (SiP) technology to address this market need by providing system designers with a compact, highly customizable, integrated solution that simplifies design, enhances performance, and saves valuable development time.1 This approach offers a great advantage to customers who want to get to market faster with advanced technology.2

What Is Precision Signal Chain μModule Technology?

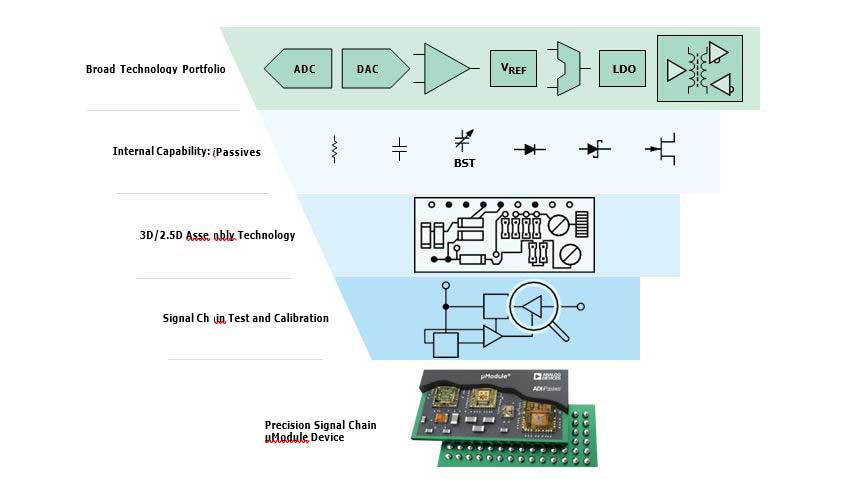

The precision signal chain μModule is a system-in-package (SiP) technology that enables the integration of diverse circuits together while maintaining the highest level of performance. ADI’s precision signal chain μModule solutions aim to enhance density in a smaller form factor by combining top-notch devices, iPassives® technology and advanced 2.5D/3D assembly technology, while

maintaining intelligent and efficient management of the system components (refer to Figure 1).1 These μModule devices serve as reliable building blocks for the signal chain, allowing system designers to achieve higher levels of integration, faster time to market, greater speed performance, and reduced power consumption at an affordable price without the need for additional external circuitry debugging or optimization.1

Key Features and Advantages

The Power of Integration:

Precision signal chain μModule solutions represent a remarkable advancement in signal chain design by integrating multiple analog and digital components into a single module. This is made possible by utilizing ADI’s iPassives technology with our superior signal conditioning ICs that are packaged up through SiP technology to create μModule devices with best-in-class performance and robustness in exceptionally short development cycle times.2 Just as integrated circuits contain many transistors, integrated passives can contain many high quality passive components packed into a very small area.

A single device can now contain systems that were previously board-level solutions. By combining functions such as amplification, filtering, and analog- to-digital conversion, these modules eliminate the need for designing complex signal chains using individual components. Hence, interconnectivity parasitics (inductance, capacitance, and resistance) are significantly reduced. All of these factors help lead to complete solutions with excellent out-of-the box performance. Developed in short development cycles with large cost saving, all in very compact packages2, this integration not only reduces the physical footprint by providing complete solutions in spatially efficient footprints, but also optimizes the performance and reliability of the signal chain. Passive components that are manufactured at the same time, under the same conditions, have a greater chance of being well-matched by which integrated passives are fabricated.2

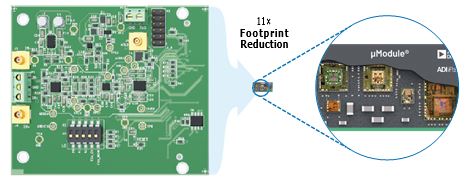

This solution reduces design iterations by transferring the component selection, optimization, and layout from the designer to the device. ADI produces precision signal conditioning systems that are highly customizable, with superior performance that is enabled by the unique silicon fabrication processes that we have at our disposal.2 Figure 2 illustrates the significant reduction in footprint offered by this solution. Beyond that, the total cost of ownership and time to market for system-level designers can be lessened.

Unleashing Performance Potential

Precision signal chain μModule solutions are designed to deliver exceptional performance to booming customer electronics demands by overcoming the limitations of front-end integrated circuit designs and fabrication technologies.3 With careful component selection, precise analog design techniques, and advanced layout optimization, these modules ensure high signal integrity, low noise, and accurate signal processing. Whether it is capturing sensor data, amplifying signals, or converting between analog and digital domains, precision signal chain μModule solutions unleash the full potential of signal processing with uncompromised quality.

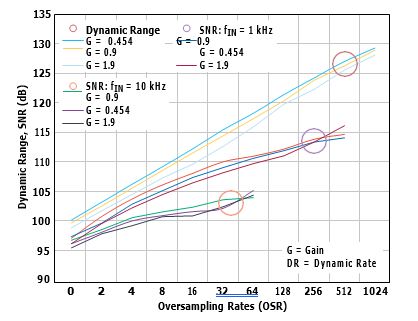

ADI’s iPassives technology guarantees a homogenous mechanical environment. To do this, interconnected parasitics such as trace resistance and inductance are kept to a minimum, while the few that are there are very predictable and can be reliably accounted for.2 Figure 3 shows the superior performance of the ADAQ4003 across different gains for various input frequencies.

Customization and Flexibility

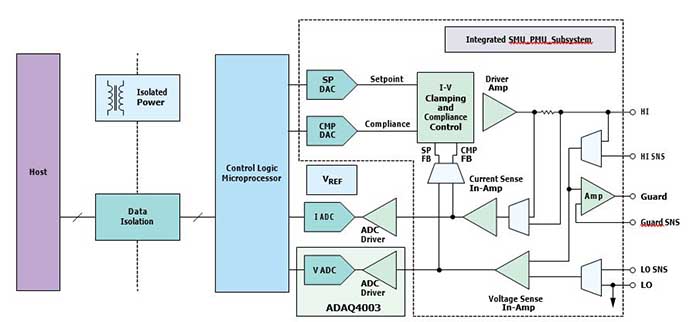

While offering integration, precision signal chain μModule solutions also provide system designers with flexibility in designing signal chains. They are highly configurable, allowing users to tailor the parameters and characteristics of the signal chain to their specific application requirements through intelligent partitioning of all the components, as shown in Figure 4. With the adjustable gain, bandwidth, filtering options, and other customizable features, these solutions offer a versatile platform that caters to a wide range of design challenges.

Reduced Total Cost of Ownership:

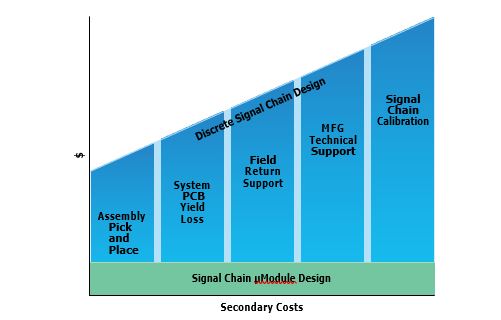

There are many secondary costs associated with supporting a system over its lifetime.1 By their very nature, discrete devices degrade invariably in their performance across the operating temperature and lifetime of the circuit. A system built with a precision signal chain μModule solution has lower secondary costs because the passive components that impact performance and yield during manufacturing are integrated into the μModule device.1 Figure 5 illustrates the reduction in secondary costs when a precision signal chain μModule solution is used instead of a discrete signal chain.

The limits reflected in the data sheet of a signal chain μModule cover the entire signal chain performance; hence, enabling consistent performance and high yield in manufacturing, which reduces the occurrence of a yield issue in the manufacturing line to help minimize tech support costs and maximize manufacturing throughput.1

Additionally, since passive components are an integral part of every electronic subsystem,5 integrating these into the substrate provides the possibility of performance improvement. Through this integration, temperature-dependent error sources are reduced. Not only that, but the need for signal chain calibration vs. temperature in manufacturing is removed wherein these factors are known to be time-consuming and expensive (refer to Figure 6). Minimizing the number of discrete components and interconnects on the PCB also improves system reliability due to fewer solder joints, which reduces field support costs.1

Ease of Use and Rapid Prototyping:

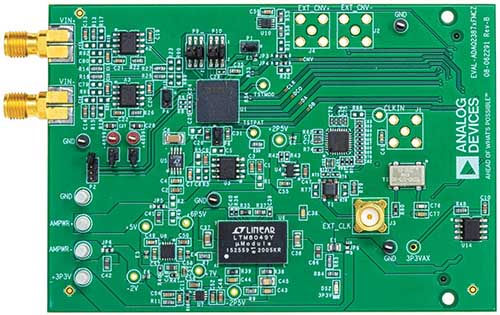

Precision signal chain μModule solutions simplify the design process and significantly reduce development time. The design time is reduced because the cores are predesigned, fabricated, characterized, and tested. The precision signal chain μModule solutions come with preconfigured signal chains, and a wealth of sup- port resources such as evaluation boards and software development kits, which means good performance and a simple design phase. Figure 7 shows a sample signal chain kit that showcases the capabilities of precision signal chain μModule solutions.

From the designer’s perspective, ADI’s iPassives technology can be viewed as a flexible design tool to produce precision signal chain μModule solutions that enable the design of system solutions in exceptionally short development cycle times.2 System designers can focus on system-level design and functionality rather than grappling with intricate circuit-level implementation. Rapid prototyping and system validation become easier, enabling aggressive schedules from system definition to part delivery for innovative applications.

To meet the varied demands of the market, ADI provides an extensive portfolio of integrated and special purpose converters to support a broad range of industries. Learn more by visiting ADI’s precision signal chain μModule solutions page.

Applications Across Industries

Precision signal chain μModule solutions provide a wide array of applications in numerous industries, spanning various domains such as the following:

Communications

Most wireless communication products require digital, analog, and RF electronics to facilitate seamless transmission and reception of signals. Precision signal chain μModule solutions provide this by enhancing the performance of transceivers, base stations, and network infrastructure. These solutions provide an effective solution in mitigating the electromagnetic interference provided by digital counterparts of noise-sensitive RF electronics by separating the RF and digital circuits.6

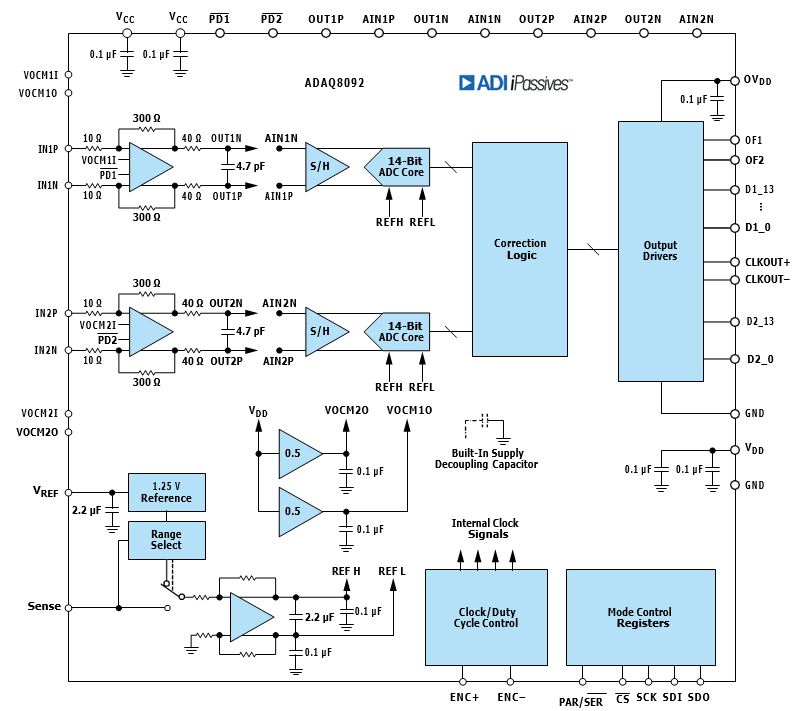

One example is the ADAQ8092 (Figure 8), which is a dual-channel system in package (SIP) that integrates three common signal processing and conditioning blocks to support a variety of demodulator applications and data acquisition applications. The device integrates all active and iPassives components to form a complete signal chain providing up to 6× footprint reduction vs. discrete solution. The built-in power supply decoupling capacitors enhance power supply rejection performance, making it a robust DAQ solution. The ADAQ8092 operates on 3.3 V to 5 V analog and 1.8 V digital supplies. The digital outputs can be CMOS, double data rate CMOS, or double data rate LVDS.

Industrial Automation

Focusing on industrial applications, recent semiconductor technology advances enable innovative trends in three main directions: power density and energy efficiency, the pervasiveness of digital power control, and safety.7 Precision signal chain μModule solutions enable precise signal processing for industrial automation systems, ensuring accurate measurements, control, and actuation.

Industrial communication networks drive smart and safe manufacturing scenarios by having real-time communication among machines and control systems. Precision signal chain μModule solutions allow the development of digital control systems along with novel connectivity solutions to ensure human safety in any point in time.7

System safety is essential for ensuring human safety and protecting the environment.7 Recent developments in new process options of semiconductor technologies ensure that compromises aren’t necessary to address the lack of communication speed, large power consumption, considerable size, and reliability concerns of safety monitoring systems.

Precision signal chain μModule solutions provide an integrated approach in terms of space saving, low power consumption, excellent reliability, and communication speed.

Industrial automation systems collect data from multiple sensor nodes and transmit the data to a central conditioning monitoring system for data analysis. Condition-based monitoring (CbM) is a preventive maintenance strategy that continuously monitors the condition of assets using various types of sensors. CbM can be used to establish trends, predict failure, calculate the lifetime of an asset, and increase safety in manufacturing plants.8

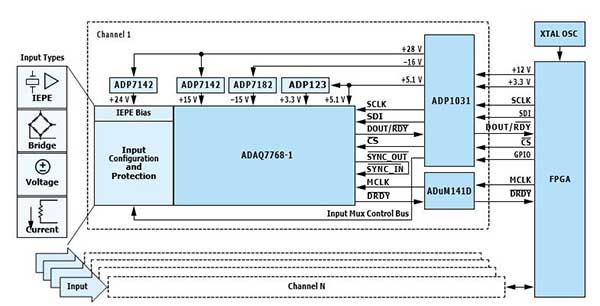

For CbM applications, the ADAQ7768-1 supports a wide variety of input types, including IEPE sensors, resistive bridges, voltage, and current inputs, as illustrated in Figure 9. The ADAQ7768-1 also supports two device configuration methods. The user has the option to choose which configuration the device will function from altering the registers through its SPI, or through a simple hardware pin strapping method to configure the device to operate under various predefined modes.1

Automotive Testing Solutions

The innovation and optimization of precision signal chain μModule solutions pro- vide robust interconnections and mechanical support, high reliability, compact, and cost-effective product that helps meet the needs of the automotive industry.9 These solutions are employed in applications such as infotainment systems, powertrain control, advanced driver assistance systems (ADAS), enhancing safety, comfort, and vehicle performance.

Technological advances drive complexity, and as such, new methods for simulation and verification are needed. To prevent impractical simulations, a digital twin can be utilized. A digital twin is a virtual representation of a real-world physical system.1 This method can help reduce costs, accelerate development cycles, or enable optimization of the overall system.

As an example from the automotive market, hardware-in-the-loop (HIL) is a digital twin technique that is used for testing complex real-time systems, such as electronic control units (ECUs), power steering systems, suspension systems, battery management systems or any other vehicle subsystems. ADI’s broad portfolio of signal conditioning, data acquisition, signal generation and isolation enable optimized solutions for HIL simulators—specifically, ADAQ23878 with signal scaling that reduces end system component count by combining multiple common signal processing and conditioning blocks in a single device including a low noise, fully differential ADC driver (FDA), a stable reference buffer, and a high speed, 18-bit, 15 MSPS successive approximation register (SAR) ADC.1

Conclusion

The new dictum in IC technology is to streamline the development process by utilizing the heterogeneous integration of SiP technology.10 The introduction of precision signal chain μModule solutions has transformed system designers’ approach to signal chain design. This solution offers integration, high perfor- mance capabilities, flexibility, and ease of use while maintaining exceptional signal processing capabilities. As technology continues to advance, precision signal chain μModule solutions are positioned to play a crucial role in enabling innovative applications across diverse industries, contributing to the advance- ment of electronic systems.

Acknowledgements

We would like to thank Stuart Servis for his technical contributions to this article.

References

- “Precision Signal Chain µModule Solutions.” Analog Devices, Inc.

- Mark Murphy and Pat McGuinness. “Use of Integrated Passives in Micromodule

- SIPs.” Analog Dialogue, Vol. 52, No. 10, October 2018.

- Man-Lung Sham, Y. C. Chen, L. W. Leung, Jyh-Rong Lin, and Tom Chung. “Challenges and Opportunities in System-in-Package (SiP) Business.” 2006 7th International Conference on Electronic Packaging Technology, August 2006.

- Maithil Pachchigar. “μModule Data Acquisition Solution Eases Engineering Challenges for a Diverse Set of Precision Applications.” Analog Devices, Inc., November 2020.

- Michael Scheffler and Gerhard Tröster. “Assessing the Cost Effectiveness of Integrated Passives.” Proceedings of the Conference on Design, Automation and Test in Europe, February 2000.

- King L. Tai. “System-In-Package (SIP): Challenges and Opportunities.” Proceedings of the 2000 Asia and South Pacific Design Automation Conference, January 2000.

- Domenico Arrigo, Claudio Adragna, Vincenzo Marano, Rachela Pozzi, Fulvio Pulicelli, and Francesco Pulvirenti. “The Next ‘Automation Age’: How Semiconductor Technologies Are Changing Industrial Systems and Applications.” ESSCIRC 2022- IEEE 48th European Solid State Circuits Conference (ESSCIRC), September 2022.

- “Condition-Based Monitoring.” Analog Devices, Inc.

- Yangang Wang, Xiaoping Dai, Guoyou Liu, Daohui Li, and Steve Jones. “An Overview of Advanced Power Semiconductor Packaging for Automotive System.” CIPS 2016; 9th International Conference on Integrated Power Electronics Systems, March 2016.

- K.M. Brown. “System in Package: The Rebirth of SIP.” Proceedings of the IEEE 2004 Custom Integrated Circuits Conference.

About the Author

Lloben Paculanan is a product applications engineer at Analog Devices in General Trias, Philippines. He joined ADI in 2000 where he worked on various test hardware development and applications engineering roles. He has been working on precision, high speed, and precision signal chain μModule development. He graduated from Ateneo de Cagayan Xavier University with a bachelor’s degree in industrial engineering and technology, and computer engineering from Enverga University.

About the Author

Regine Garcia joined Analog Devices in 2023 and is currently a product applications engineer for precision signal chain μModule development at ADI in General Trias, Philippines. She earned her bachelor’s degree in electronics and communications engineering from Saint Louis University in Baguio City.