Smoke Detection and Why It Matters

Smart building technology is evolving to transform static buildings into living, efficient entities known as intelligent buildings. This development requires technologies to drive lower running and maintenance costs. The megatrend of greener buildings, zero emissions, and a lower carbon footprint requires more modalities to be monitored and controlled within a building. Some of these solutions and measurements are to enhance worker comfort and productivity. However, buildings also require solutions and measurements for safety, which are being driven by increasingly stringent regulations.

In safety, smoke detection has the biggest challenge: saving lives.

The smoke detection market has innovated due to some key factors, including:

▶ Growth in industrial buildings: The International Energy Agency (IEA) predicts growth in global buildings’ floor area at approximately 3% per year. This is driven by increasing urbanization and improved access to energy in developing countries.

▶ The increasing use of synthetic material within buildings. That’s why, where the value proposition is as basic as human life, smoke detection regulations are critically important. The challenge is that false evacuations can cause downtime and panic, particularly as buildings are now designed to hold thousands of people (for example, the Boeing Everett Factory in Washington was designed to hold approximately 40,000 people). Kitchens that generate cooking vapors or steam can cause false alarms in precisely the locations where smoke detectors should not be disabled due to nuisance alerts. In a genuine emergency, there is now less time to evacuate a building due to synthetic materials that may be smoldering and where fumes can quickly kill. New fire regulations now specify there should be minimal false alarms and an increasingly faster alert time for real fire incidents. This article will examine some of the pending and current global standards and what it means for smoke detection technology and its market.

There are two predominant smoke detection technologies used in smoke detector systems:

▶ Ionization systems have a small amount of radioactive material between two electrically charged plates. This ionizes the air and causes current to flow. When smoke enters the chamber, it reduces the flow of current and activates the alert/alarm. Some European countries and U.S. states have banned the use of ionization detectors because they have not always detected early state fires.

▶ Photoelectric smoke detectors use light to detect fire. Inside the alarm, there’s a light-sensing chamber that uses light to detect smoke. When smoke is present, it deflects the LED light into a photodetector. As soon as light beams hit this sensor, the alarm is activated.

A Summary of Global Standards

There are basically five main global standards to compare with different requirements to pass respective certification. Smoke detector systems need to be fully tested as an end product, but there is also testing that can happen at the subsystem level of smoke detection technology. This does not substitute for the full certification, but can give peace of mind before costly end system certification.

U.S. and Canada

▶ UL 268: Smoke Detectors for Fire Alarm Systems

- 7th edition: due to come into effect in May 29, 2020, although it may be delayed until June 30, 2021

▶ UL 217: Smoke Alarms

- 8th edition: due to come into effect in May 29, 2020, although it may be delayed until June 30, 2021

These standards include updates to the polyurethane flaming and smolder- ing and cooking nuisance (hamburger) test.

Europe

▶ EN 14604: Smoke alarm devices (2006)

▶ BS EN 54: Fire detection and fire alarm systems (2015)

- Part 29: Multisensor fire detectors—Point detectors using a combination of smoke and heat sensors

International

▶ ISO 7240: Fire detection and alarm systems (2018)

- Part 7: Point-type smoke detectors using scattered light, transmitted light, or ionization

▶ Chinese standard for point-type smoke detectors follows 2003 edition of this standard

UL 268 and UL 217 cover U.S. and Canadian regulations and are the standards that effectively require technologies (and algorithms) to differentiate between a specified concentration of smoke from a flaming polyurethane foam pad and a specified concentration of smoke from burning hamburger. Note: Canadian regulations require a different smoke test chamber setup. The other three standards are EN 14604, which is a European standard published in 2006; BS EN 54, which is the British interpretation of the European EN 54 standard published in 2015 (part 29 of this standard refers to smoke detection); and ISO 7240, which is an international stan- dard published in 2018 (part 7 of this standard is relevant for smoke). The current Chinese standard for point-type smoke detectors follows the 2003 version of ISO 7240.

Detail on Testing

There are two aspects to each standard that we will discuss next: the tests and the requirements for test set up. The following example uses the UL standards.

▶ The typical dimensions of d = 5 ft or 2 m and a beam diameter 4″ to 6″ (10.2 cm to 15.2 cm) uses a sodium vapor lamp (589 nm). d is the distance from the light source to the photodetector.

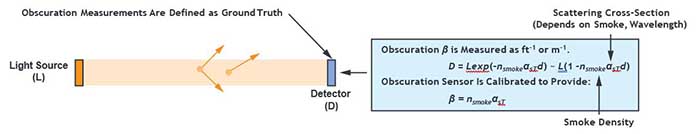

Fire room tests are expressed in terms of time to alarm after initiation of fire or in terms of obscuration levels (or in some cases both). Obscuration is a unit of measurement for the concentration of smoke. It measures the amount of light that reaches the detector (D) in the presence of smoke compared to the amount of light that reaches the detector (D) in clean air. The higher the value of obscuration, the higher the smoke concentration levels.

The most stringent testing standards are currently NA/Canada UL 217 and UL

268. Some of the relevant tests are listed here, but there are many more: UL 217 (8th edition)/UL 268 (7th edition)

▶ Paper Fire

- Must give an alarm before t = 240 s

▶ Wood Fire

- Must give an alarm before t = 240 s

▶ Smoldering Smoke

- Must give an alarm before obscuration levels exceed 29.26%/m

▶ Flaming Polyurethane Foam

- Must give an alarm before obscuration levels exceed 15.47%/m and t = 360 s

▶ Smoldering Polyurethane

- Must give an alarm before obscuration levels exceed 34.3%/m

▶ Hamburger (Nuisance Alarm)

- Must not give an alarm/fault before obscuration levels exceed 0.987%/m or the MIC value is in the 59.3% to 49.2% range

▶ Sensitivity Test, Dust Test, High Humidity Test

- Must not give an alarm/fault

- The sensitivity test measures the obscuration level at which the unit alarms in a controlled smoke chamber

▶ Flammable Liquid Fire (UL 268 Canada Only)

- Must give an alarm before t = 240 s

For EN 14604, BS EN 54, and ISO 7240, there can be different sensitivity lev- els on the same test or additional specifications pertaining to, for example, liquid (heptane) fire, glowing smoldering cotton, or low temperature, black smoke liquid fire.

Note: for a complete set of tests, the relevant specification must be refer- enced in full.

Provisions for Testing and How International Regulations Can Overlap

The following are the requirements for the five main test regulations:

▶ UL 268 and UL 217

- 28 assembled specimens, all of which are used for each test (unless otherwise agreed with the testing agency)

▶ EN 14604

- 20 specimens: specimens numbered in order of increasing response threshold (decreasing sensitivity)

▶ BS EN 54

- 22 specimens: six least sensitive specimens numbered 17 through 22 and the others arbitrarily numbered 1 through 16

2 Smoke Detection Technology for Buildings: Navigating the Myriad of Regulations and Certifications

▶ ISO 7240

- 20 specimens: four least sensitive specimens numbered 17 through 20 and the others arbitrarily numbered 1 through 16

The test sets are important as they determine how many detectors are needed for each test within the five standards. UL 268 and UL 217 require 28 specimens, all of which are used for each test. For the other three stan- dards, the specimens are numbered as detailed and specific specimens are then required to pass specific tests. For example, in ISO 7240 all specimens are tested for the reproducibility test, yet only specimen 3 is tested for the dazzling light test. What this means for global compliance is that, because specific devices are required to pass specific tests for compliance, each test in each standard must be performed and standards cannot be overlapped. In some cases, the testing conditions are identical between the two differ- ent UL standards, so compliance with one standard will mean compliance with the other.

EN 54-29, EN 14604, and ISO 7240 have identical requirements for the smoke tunnel and fire room—both of which certain tests are carried out in. The required atmospheric conditions for these standards are also identical. In some cases, the testing conditions are identical between the two different UL stan- dards, so compliance with one standard will mean compliance with the other.

Smoke Detection Technology: One Size Does Not Fit All

This article has summarized some smoke detection technologies, defini- tions, and smoke detector tests and how they relate to five international standards. It is not meant to be a detailed analysis of one standard over another. Instead, the article uses some examples to show how stringent and complicated the process to meet smoke detection regulations can be. Each international region has a very detailed set of tests that have different methods (and setups) for testing.

However, passing UL 217 and UL 268 standards—currently the most strin- gent pair of standards—can give a good indication of compliance, although this is not a substitute for regional testing. For regional compliance, a very detailed examination of local test requirements and methods is required. Even at local country level, regulations will increasingly become more stringent in the future.

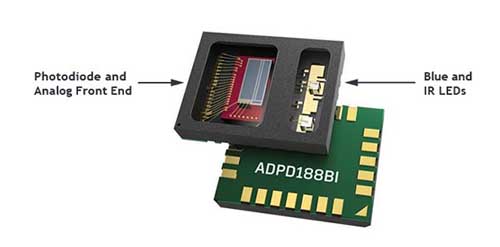

Using a component or subsystem that is UL listed provides ease of mind. UL component recognition means that UL has evaluated components or materials intended for use in a complete product or system. These components are intended only for end-use products that may be eligible for UL certification. The ADPD188BI plus smoke chamber is pending for UL listing as of the publication of this article.

The ADPD188BI smoke detection module integrates LEDs, a photodiode, and an analog front end (AFE) in one small 3.8 mm × 5.0 mm × 0.9 mm package. The benefits include:

▶ A reduced component count

▶ Meets new and existing regulations for life safety due to a high signal-to-noise ratio (SNR) and wide dynamic range for lower signal measurement

▶ Reduced nuisance alarms to ensure verified alerts (and avoid alarm dis- able) by having two color detection and high dynamic range

▶ Low power dissipation to allow more devices on wired or wireless loops

▶ Small size to enable placement of detectors in hard to reach places

▶ The elimination of LED supply chain management requirements

▶ Running on a standard SMT assembly process

The Future

Regulatory changes have driven the trend for smaller, more accurate smoke detection systems. In addition to the regulatory changes, customers are demanding better aesthetics and a wider range of trickier deployment scenarios. Meeting this demand will require smaller form factors at lower power. Systems that use dual wavelength detection can reduce nuisance alarms, which is a requirement of the new test regulations. Systems with a higher SNR and high dynamic range also help here as well as in the better identification of smoke type. Optical technology enables a high dynamic range to help increase reliability, create a smaller form factor, and/or reduce power consumption.

Because nuisance alarms like cooking or steam are now eliminated, smoke detectors can be fitted in areas like kitchens and bathrooms in higher densities, with more physical devices present through buildings enabling larger networked systems. Therefore, lower power requirements will enable battery operation (longer lifetime) or more devices on a main’s loop. But at a system level, for wireless networks, the faster alert requirement means the need for low latency networks. Because of the life safety aspect of smoke detection, the physical system will continue to remain as a standalone unit. However, in the future, there may also be the need to incorporate smoke detection into other building control systems—for example, within evacuation or emergency lighting, where a smaller form factor will become increasingly important.

About the Author

Grainne Murphy is a marketing manager with Analog Devices’ Industrial and IoT Solutions Group. With over 25 years of engineering experience, she manages customer needs, engagement, and market- ing/communications strategy for ADI’s key product portfolios and future direction within intelligent buildings. She is a University of Limerick, Ireland graduate (B.Eng.) and holds an M.B.A. from Oxford Brookes University. She can be reached at grainne.murphy@analog.com.