In the rapidly evolving landscape of NewSpace technology, power management in analog devices has become more important than ever. Ensuring optimal performance in the harsh conditions of space demands innovative solutions that balance high power density and thermal management. Apex Microtechnology offers industry-leading analog devices that maximize performance while minimizing design space. In this article we will explore how Apex’s integration of high-power components and the reduction of package size contribute to enhanced efficiency with reliability in mind. Furthermore, we will discuss the importance of an efficient stackup design to optimize thermal dissipation, ensuring our devices meet the rigorous demands of NewSpace applications.

Inherent power density

Since its founding, Apex has provided power amplifier solutions that are capable of dissipating high-power efficiently in compact packages that allows for ease of integration in systems with limited board space. The need for servicing applications that have a ‘tight fit’ with regard to their internal components has influenced the Apex product portfolio to consist of compact power amplifier modules that can conveniently provide power that would normally be attributed to much larger discrete circuits. This ability to support high-power applications with a minimum board footprint illustrates the power density that Apex can provide for NewSpace applications that are constantly trying to minimize weight and overall size dimensions in order to satisfy their design requirements. The size of Apex products coupled with their output power specifications also makes them ideal for multichannel applications or other systems in NewSpace that might require redundant modules.

Integration of high-power components

Being that Apex is a manufacturer of high-power amplifier modules, it would follow that product offerings from Apex consist of high-power internal components. Output stages of most Apex products can support multiple amps of continuous output current. The layout and substrate are chosen such that they facilitate quick and direct heat spreading from the output power devices down through the package layers and into whatever heatsink medium is applied. This level of power dissipation is crucial for systems that are designed with reliability and robustness in mind.

Reduced package size

One defining characteristic of Apex products is their overall compactness. During the design phase of these products, circuit area is reduced to as little as possible while still adhering to established voltage breakdown specifications. Developing packages of miniature proportions that can still dissipate power efficiently is no small task. A lot of time and effort are put into the package designs that house Apex products with one thing in mind: power dissipation. Providing high power solutions in relatively small packages is conducive to servicing multiple industries that require compact solutions, including NewSpace. Many of the applications that are being devised in the NewSpace market are dependent upon the amount of available area to include necessary components for their mission. The focus on reducing the package size of Apex product offerings is complimentary to this dependence and makes them worthy of consideration for any NewSpace application.

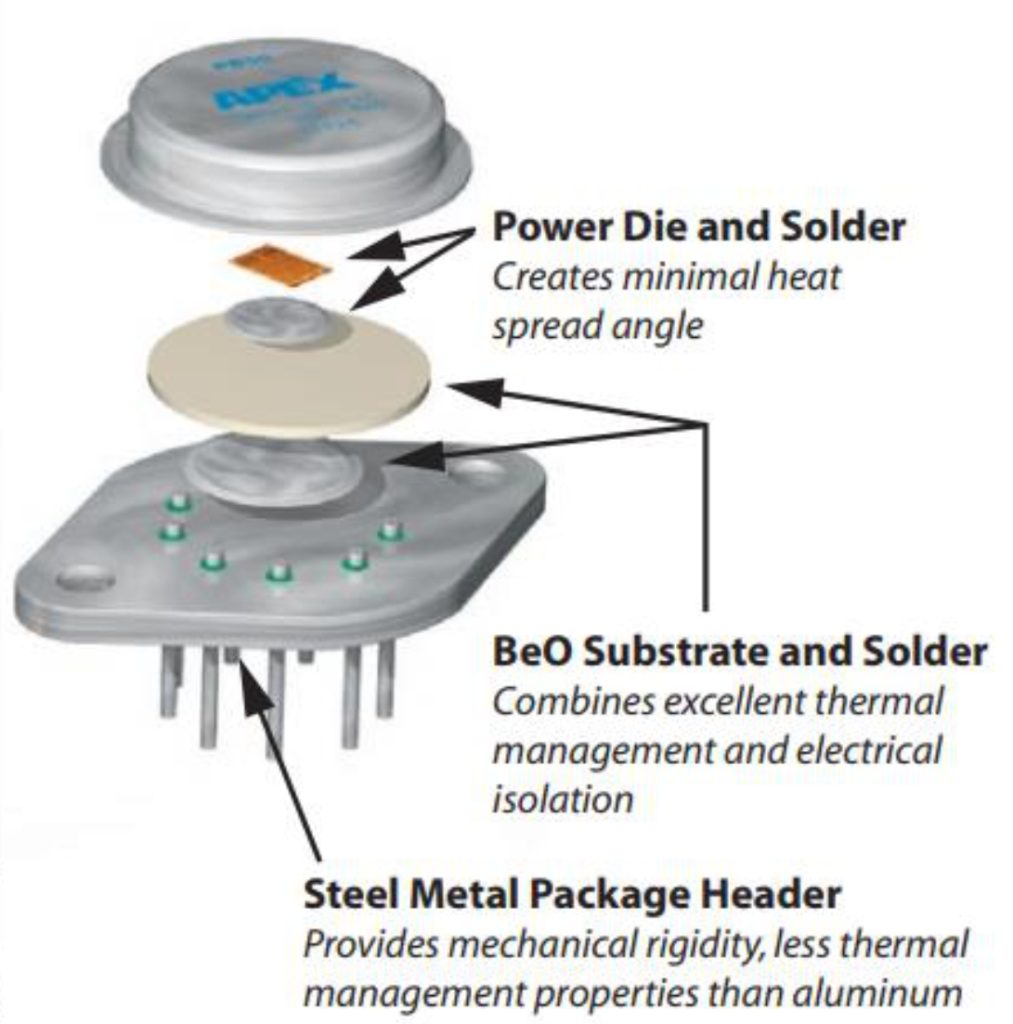

Efficient Stackup for max thermal dissipation

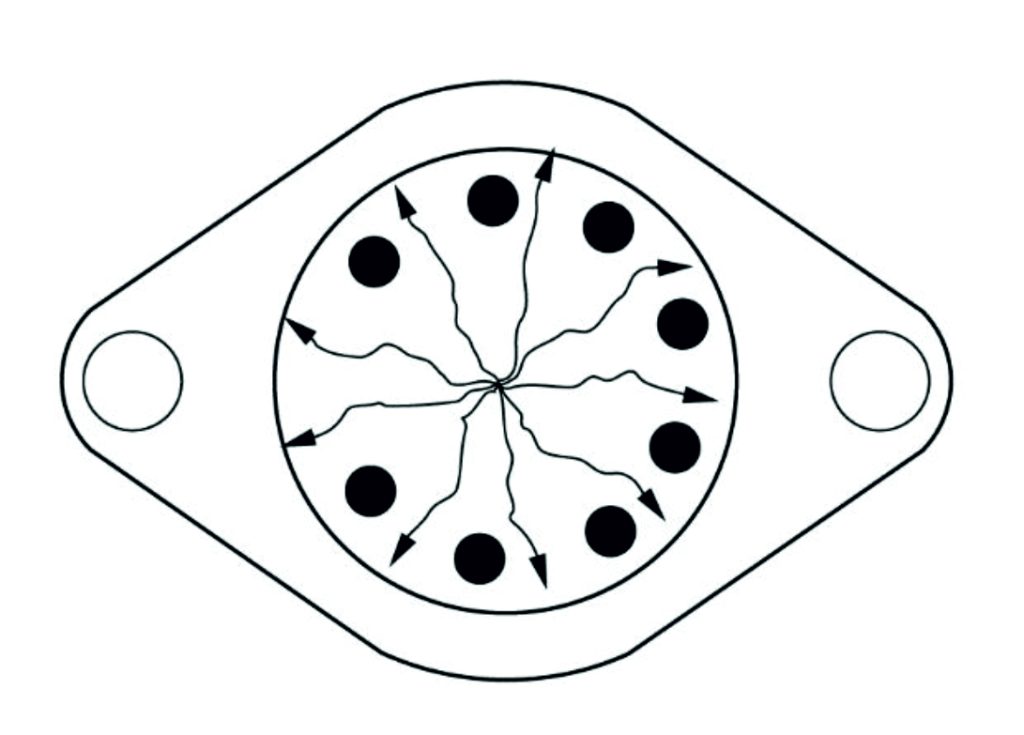

The architecture of Apex products regarding power management can be further elucidated by examining the stack up of the output power components. The output power components of a given Apex product are chosen such that they have a healthy margin when it comes to current output capability to ensure robustness when asked to deliver power to a load. These components are then mounted to a substrate of BeO(Beryllium Oxide), which, among other things, is known for its excellent thermal transfer characteristics. This layer of BeO, which acts as a heat spreader to ensure the entire circuit is thermally matched, is then attached to a device pin header composed of cold rolled steel that will interface with some heat sink material. This interface is then normally enhanced with the aid of a thermal interface material for adequate mating of dissipative surfaces. Many devices from the NewSpace market can find themselves in low earth orbit with no real possibility for repair, so efficient power dissipation becomes a necessity when high reliability is a must.

Recently, Apex Microtechnology released a new product line of radiation-tolerant operational amplifiers to serve the NewSpace market and applications in radiation environments. Apex’s Rad-tolerant “R” devices are tested to maintain operability after exposure to certain levels of radiation. These devices include radiation data for HDR, ELDRS/LDR, and SEE testing, in addition to TID lot traceability and PIND data. Radiation tolerant devices are based on a Class H military grade that includes additional screening such as burn-in testing, which further speaks to device reliability. To learn more visit, apexanalog.com