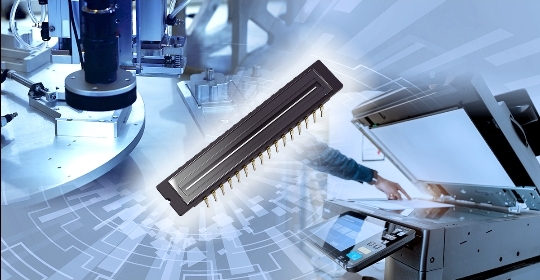

Forget bulky scanners and clunky machines. The sleek, efficient document scanners, sophisticated industrial inspection systems, and high-precision measuring instruments we rely on today owe a significant debt to a clever optical trick: the Lens Reduction Type CCD Linear Sensor . This technology revolutionized imaging by shrinking the physical footprint without sacrificing critical performance, paving the way for the compact devices we take for granted. Let’s delve into the fascinating world of these miniaturized marvels.

The Challenge: Size Matters in Imaging

▪The 1:1 Barrier: Traditional linear imaging for applications like scanning requires capturing the full width of an object (e.g., a sheet of paper) directly onto a sensor array of equal length. This meant sensors had to be physically as wide as the largest object they needed to scan. Imagine a scanner needing a sensor 8.5 or 11 inches long!

▪Bulk and Cost: Manufacturing very long, defect-free CCD arrays was (and remains) technically challenging and expensive. The sheer size also dictated larger, heavier, and more cumbersome equipment designs.

The Ingenious Solution: Optical Shrink Ray

▪Core Principle: Demagnification:The lens reduction approach tackles the size problem head-on using fundamental optics. Instead of projecting the object at its actual size (1:1 magnification) onto the sensor, it uses a specialized lens system to project a reduced (demagnified) image of the object onto a significantly shorter CCD sensor.

▪The Reduction Lens: This is the heart of the system. It’s a high-quality lens designed specifically to create a sharp, smaller image of the scanned line. Common reduction ratios are 1/2, 1/3, or even 1/4. For example, scanning an 8.5-inch wide document with a 1/4 reduction lens only requires a sensor roughly 2.125 inches long.

Anatomy of a Lens Reduction CCD Linear Sensor System

1. Illumination Source: Provides consistent, uniform light across the width of the object being scanned (e.g., fluorescent lamp, LED array).

2. Object Plane: The surface containing the line of information to be captured (e.g., the document on the scanner glass).

3. Reduction Lens Assembly: Carefully designed lenses (often multiple elements to correct aberrations) that collect light reflected from or transmitted through the object line and focus a smaller , inverted image.

4. Shorter CCD Linear Sensor: The star of the show. This Charge-Coupled Device sensor is a single row (or a few staggered rows for color) of thousands of tiny, light-sensitive pixels (photosites). Its physical length is determined by the reduced image size, not the original object width.

5. Drive Electronics: Precisely controls the CCD’s charge transfer and readout timing.

6. Signal Processing Circuitry: Amplifies the tiny analog voltage signals from each pixel, converts them to digital values (Analog-to-Digital Conversion – ADC), and performs initial processing (like shading correction).

Why Shrink? The Compelling Advantages

▪Dramatic Size & Weight Reduction: This is the primary driver. Smaller sensors mean vastly more compact, lighter, and cheaper overall systems. Think flatbed scanners fitting on desktops instead of requiring large dedicated tables.

▪Lower Sensor Cost: Manufacturing shorter CCD linear sensors is inherently less expensive and yields higher quality (fewer defects per sensor) compared to producing very long 1:1 sensors.

▪Simplified Optics (Potentially): While the reduction lens needs high quality, designing a system for a smaller image circle can sometimes be simpler than designing a perfect 1:1 lens covering a huge field.

▪Increased Design Flexibility: The compact sensor allows for more creative and ergonomic product designs.

Navigating the Trade-offs: Considerations

▪Lens Complexity & Cost: Achieving high resolution and low distortion over the demagnified field requires sophisticated, multi-element lenses. The cost and quality of the reduction lens are critical. A poor lens negates the benefits of the smaller sensor.

▪Depth of Field: Reduction systems can sometimes have a slightly shallower depth of field compared to simpler 1:1 imaging setups, requiring more precise focus.

▪Light Efficiency: The demagnification process concentrates light onto a smaller area, which is generally good. However, light loss within the lens elements themselves needs to be minimized through good lens design and coatings.

▪Resolution Potential: While the sensor resolution (pixels per inch *on the sensor) can be very high, the effective resolution of the scanned image depends on the lens quality and the reduction ratio. The lens must resolve detail finely enough to match the sensor’s capability at the reduced scale.

Where the Miniaturized Marvels Shine: Key Applications

▪Desktop Document Scanners: The dominant technology enabling compact, affordable home and office scanners.

▪Flatbed Scanners: Found in multi-function printers (MFPs) and dedicated scanning devices.

▪Industrial Inspection Systems: Used for high-speed, automated visual inspection of webs (paper, plastic, metal), textiles, printed materials (PCBs, labels), and manufactured parts where space constraints exist.

▪Precision Measurement Instruments: Employed in systems measuring dimensions, profiles, or surface features of objects.

▪Graphic Arts & Film Scanning: Some high-end film and transparency scanners utilize this approach.

▪Spectroscopy: In some spectrometer designs for analyzing light spectra.

The Enduring Legacy

While newer technologies like CMOS linear sensors gain traction, the fundamental principle of lens reduction remains highly relevant. It elegantly solved the critical problem of sensor size that plagued early linear imaging. By leveraging optical demagnification, lens reduction type CCD linear sensors made high-performance scanning and linear imaging accessible, affordable, and compact. They are a testament to clever engineering, proving that sometimes, seeing things smaller is the key to building bigger possibilities. As long as there’s a need for precise, space-efficient capture of linear information, this ingenious optical approach will continue to have a vital role.

Written By :

Vinayak. Ramachandra. Adkoli.

–—–