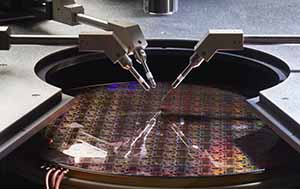

Artificial intelligence is reshaping nearly every sector, from autonomous vehicles and healthcare to high-frequency trading and industrial automation. At the heart of this revolution lie the microchips powering AI models and decision engines—advanced silicon devices engineered to process massive data streams with speed and precision. But as chip complexity grows, so too do the challenges of testing them.

Testing AI chips isn’t just about checking functionality. It’s about ensuring each device performs reliably under real-world conditions, across countless workloads, voltage levels, and signal types. As the race to build faster, smarter chips accelerates, the ability to test thoroughly, quickly and consistently has become a major pressure point for semiconductor developers and test engineers.

Why Testing AI Chips is So Complex

Modern AI chips are no longer simple logic devices. They combine digital cores with analog interfaces, integrate multiple processing units like CPUs, GPUs, NPUs and often use 3D-stacked dies to increase bandwidth. They must handle large volumes of data across many channels while consuming minimal power. For test systems, that means simultaneously managing:

- High-speed digital signal switching

- Precise analog measurements

- Multiple voltage domains and current levels

- Synchronised timing across cores

- Realistic power delivery and thermal loads

To make matters harder, the chip architectures themselves are evolving rapidly. Neural cores can operate in bursts of high activity, which results in fluctuating power demands. Memory hierarchies are more complex. And many chips now feature protocol-specific I/O that must be validated under real-time conditions.

The test hardware must evolve in parallel. This includes everything from high-performance mixed signal testers to the relays that form the switching backbone of the system.

The Role of Reed Relays in AI Chip Testing

When testing AI chips, speed and accuracy are critical, but so is physical connectivity. Semiconductor testers rely on precise routing of signals from the device under test (DUT) to measurement instruments, often across a massive matrix of channels. Relays form the core of that switching infrastructure, and reed relays are uniquely well-suited to the job.

Unlike solid-state switches or electromechanical relays, reed relays offer:

- Reliable physical contact for true signal integrity

- Low contact resistance and extremely low leakage currents

- Compact size, ideal for dense switching matrices

- Fast switching times to reduce overall test cycles

- Long mechanical life, with some capable of up to a billion operations under low-load conditions

Reed relays help ensure clean, repeatable switching in systems where signal clarity and isolation are non-negotiable. This is especially valuable for sensitive low-level testing and high-frequency applications where crosstalk or signal degradation could mask chip performance issues.

Pickering Electronics, for example, offers reed relays that cover a vast range of requirements: from ultra-low leakage devices ideal for testing at millivolt or microamp levels, to high-voltage versions with up to 20 kV standoff capability. This versatility is critical in AI chip test setups, where different blocks of a chip may require completely different test conditions.

Supporting Kelvin Testing and Multi-Domain Verification

AI chips are often tested using Kelvin or 4-wire measurement techniques, which require two relays per connection point, unless dual-pole relays are used. Pickering offers an extensive range of 2-pole reed relays that reduce the relay count and PCB footprint for these setups. This not only simplifies the design of large switching systems but improves reliability and test throughput.

Reed relays also play an important role in power domain management. AI chips feature multiple voltage and current domains, each needing to be isolated, switched and monitored independently. Reed relays enable safe, controlled switching across these domains without compromising accuracy or introducing interference.

Keeping Up With Rapid Development

AI chip designs are changing fast. Time-to-market pressures are intense, and test systems must be flexible and scalable to handle new architectures. Pickering reed relays, with their modular packaging, configurable contact types, and range of voltage and current ratings, provide a level of adaptability that helps test engineers respond quickly to changing requirements.

In high-speed, high-site-count systems, relays must operate quickly and consistently to avoid bottlenecks. Devices with switching times as low as 80 microseconds, like those in Pickering’s high-speed series, help ensure that switching delays don’t slow down the entire test sequence.

Conclusion

AI chips are among the most advanced and complex devices ever produced. Testing them demands speed, precision, and adaptability—qualities that must extend throughout the entire test infrastructure. Reed relays, with their unique mix of physical performance, signal fidelity and compact design, play a vital supporting role in this process.

As chip designs become more ambitious, test engineers will need solutions that are not only high performance, but also versatile and scalable. Whether validating power integrity across multi-domain systems or ensuring precise signal routing in dense matrices, reed relays remain a trusted and essential component in the test engineer’s toolkit. To discover more about testing semiconductor wafers, check out Pickering’s semiconductor testing guide at https://www.pickeringrelay.com/semiconductor-application