Electronics manufacturers are facing daily challenges to be competitive in a global environment. The quality of the manufactured products, price pressure, and manufacturing process sustainability are just some of the tasks to place the future of electronics manufacturing on sound footing. Equipment suppliers can efficiently support this. SEHO Systems GmbH, one of the leading manufacturers of complete solutions for soldering processes and automated production lines, is in close contact with customers worldwide. Resource-efficient and energy-efficient machines, flexibility and a higher degree of automation in terms of process control are major approaches for the beneficial support of electronics manufacturers. SEHO scrutinized the soldering processes and refined them in this direction.

Activation of component and board surface is the basic requirement to get a connection between solder and terminals. The flux takes over this task.

Significant savings in flux consumption can be achieved if it is not applied over the entire surface of the entire assembly.

Selective Flux Application in Wave Soldering Processes

If the flux is selectively applied to the solder joints, even in conventional wave soldering processes, savings of up to 75% are possible, depending on the product.

The SEHO SelectFlux is designed for these applications. The system is equipped with three different nozzles that can be programmed individually or in combination. This allows individual spray widths of 10 mm to 60 mm to be generated.

The process flow of the SelectFlux is optimized to meet the comparatively short cycle time of a wave soldering system. The flux application takes place, for example, while the assemblies are passing through without stopping them. Unnecessary waiting times are eliminated by taking over the assemblies from upstream systems or passing them on to downstream systems in parallel.

The selective application of flux in conventional wave soldering processes thus offers several advantages: Without negatively affecting the cycle time, the flux consumption is effectively reduced, the effort for cleaning and maintenance is reduced and at the same time the process and product quality is improved.

Energy-efficient Preheat Process

Approximately 70 percent of the electrical energy consumption of a wave soldering system is needed to preheat assemblies. In regard to energy efficiency, several aspects of a machine must be considered and, depending on the product mix, more than one may need to be optimized to achieve the best energy efficiency.

In “shut off” mode, the machine typically needs a longer period of time to prepare for production. In the “standby” mode, the machine only needs a few minutes to reach the ready state. If the machine is in the “no load/ready” mode, a product can enter any time because there is no product in process. In “variable load” mode, fewer products enter the machine than it would be able to process. Maximum throughput is reached in “100 percent load” mode.

Due to increasing product variety and lower batch volumes, advanced technologies are required to achieve constantly good solder connections. Otherwise, it would be necessary to set up several small machines instead of one large one. This, however, would raise costs in terms of floor space requirements, maintenance requirements and energy consumption.

The energy consumption of a wave soldering system can be reduced for “no load” as well as “variable load” modes by using a new type of fast reacting pulsar heaters in the preheat area. These heaters can switch between parameter settings from one product to another without delay.

There are three factors that play a major role in achieving remarkably reduced energy consumption:

• When the machine is empty and changes into standby mode, the heaters can be set to a minimum since returning to a work setting takes only seconds. The necessary power to keep the environment in the machine on a constant level is about 3.5 kW. This minimal energy supply is enough to effectively keep the temperature level in the tunnel, avoiding any influence on the temperature profile of the products.

• If the load is less than 100 percent, all heaters not having a product running above them can be switched to a standby setting. Therefore, fewer loads are linked directly to a lower energy consumption.

• One of the main benefits of the new pulsar heaters is their quick reaction time. When processing various products with different thermal demands that require different parameter settings, no waiting time between the product groups is necessary. Configuring emitters individually instead of using entire segments helps to realize the shortest assembly distances. This means that each of the heaters below the product is activated with the particular setting for this product and no setting adjustment is needed for the next product.

As a result, the wave soldering system achieves an outstanding flexibility, which is the basic prerequisite for cost-efficient high-mix operation without throughput loss.

Flexibility Along the Line

Flexibility in the preheat area can only reach its full effectiveness if there also is flexibility in the soldering area. Most wave soldering systems installed in electronic productions are equipped with one or two solder nozzles that generate a turbulent wave. This configuration is ideal for most products. However, this concept reaches its limitations if, for example, PCBs in masks are to be processed. Generally, the packing density on both sides of a PCB increase and the portion of SMD components located on the soldering side of the THT components is continuously growing.

Switching the process to selective soldering is not always an option. If the existing wave soldering machine is used for these applications, soldering masks are an effective solution. Soldering masks eliminate an additional process step where SMD components are glued before they are soldered with the THT components. When using soldering masks, particular areas on the assembly such as SMD components or temperature-sensitive components are covered to prevent them from being wetted during the soldering process. The reliable wetting of all solder joints, however, is not guaranteed, depending on the thickness of the mask and the size of the cutouts. Additionally, it might be challenging to achieve a reproducible process if the distances between covered SMD components and the THT pins to be soldered are too small. Sophisticated assemblies that are processed in soldering masks often show soldering defects such as incomplete solder joints or solder bridges. Thus, these kinds of applications require new solutions.

Higher Process Reliability with Automation

Automatic nozzle height adjustment that does not influence the wave soldering system’s cycle time provides an innovative approach for these applications. The height of each solder nozzle can be adjusted via the software within a total distance of 20 mm, creating the optimal product-specific distance between circuit board and solder nozzle. The automatic nozzle height adjustment provides additional process reliability and better product quality because all solder joints will be reliably wetted and a component-specific defined solder peel-off will be enabled.

The system is linked to the sector soldering feature. This function allows program parameters for pump revolution speed (wave height) and conveyor speed individually for up to 16 circuit board sectors. By adding the individual nozzle height, i.e. the optimum distance between PCB and solder nozzle, at up to 16 different circuit board sectors, this system provides a large process window and maximum flexibility. It also ensures sustainability of the wave soldering machine regarding future applications.

Automated process control systems increase the reliability and stability of the soldering process significantly. Additionally, they reduce the risk of potential soldering defects, thus decreasing overall manufacturing costs. The fundamental parts of a soldering system are monitored such as temperatures in the preheat area, filling levels of flux reservoir and solder pot or the transport of assemblies through the machine using appropriate sensors. However, the consistent height of the solder wave also is crucial for wave soldering processes. An irregular wave height can result in poor hole fill or incomplete wetting, and it is no coincidence that the wave height is automatically monitored and regulated in selective soldering processes.

Until now, it has not been possible to measure the wave height in conventional wave soldering processes without interrupting the production process and using external measuring instruments.

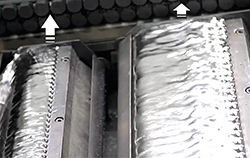

However, in this case, the result is just a momentary snapshot that does not provide any information about necessary parameter modifications and does not support automated feedback control. With a particular focus on this aspect, SEHO developed an automatic wave height measurement, built into the soldering section of the MWS 2300. The system is based on a contact measurement that produces reliable results and processes for laminar as well as turbulent solder waves.

A reference measurement is performed to determine the ideal state of the solder wave height. The measured values as well as the configured machine parameters are stored in the system. Following a customizable timetable, the system performs automatic measurements of the wave height in production mode by lowering a bar with sensor contacts onto the solder wave surface. Based on the measured values and a mathematical model, the wave height is adjusted automatically within configurable tolerances by modifying the parameters accordingly.

If the required settings are outside the defined tolerance range, the system calculates a recommendation. However, the machine operator or process owner needs to decide whether the wave height adjustment parameter modifications should be applied, or if the problem is elsewhere. All measured values and adjusted parameters are logged to ensure complete traceability, thus providing a proof of quality of the manufactured products.

The advantages are obvious: Deviations from the ideal state of the process can be recognized quickly, and potential causes can be eliminated promptly. This ensures highest product quality and reduces manufacturing costs sustainably as rework will be avoided.

Conclusion

Electronics manufacturing is in a continuous process of change. Sustainable production processes, the ability to react flexibly to new requirements, consistently high quality levels, and overall cost optimization are the goal. Innovative technologies help to establish more efficient processes and often are the small details that make the difference.