Radiation hardened electronics are engineered to function reliably in environments with increased levels of ionizing radiation. Standard commercial electronics can malfunction, degrade, or fail when exposed to radiation due to disruptions at the semiconductor level. In contrast, rad-hard components are designed with special materials, manufacturing processes, and circuit designs to resist these effects and maintain performance under duress.

With the expansion of space missions and modernization of defense systems, the demand for radiation hardened technologies is gaining considerable traction across both government and commercial sectors. Let’s explore the fundamentals of these electronics and the key factors propelling the radiation hardened electronics market forward.

What Makes Radiation Hardened Electronics Different?

Radiation hardened electronics are fundamentally distinct from conventional components. This is due to their ability to endure and operate reliably in environments with high radiation levels. The ionizing radiation in space, nuclear reactors, and defense systems can cause severe disruptions to semiconductor devices. The disruptions can result in failures such as data corruption, circuit damage, or complete system shutdown.

To prevent these risks, radiation hardened components are specifically engineered to resist three primary radiation effects. These include:

- Single Event Upsets (SEUs), which can flip bits and alter logic states

- Total Ionizing Dose (TID), which gradually degrades material properties over time

- Displacement Damage Dose (DDD), which disrupts atomic structures within the semiconductor lattice.

Where Are They Used?

Radiation hardened electronics are indispensable in environments where traditional components would quickly degrade or malfunction due to high levels of ionizing radiation.

Space Exploration and Satellites

Outer space is full of cosmic rays, solar flares, and charged particles from the Van Allen belts. These rays and particles pose a constant threat to electronic systems. Radiation hardened electronics are crucial for ensuring the reliable operation of satellites, planetary rovers, and space stations. These components prevent mission failure by maintaining integrity in the face of constant radiation exposure.

Defense and Military Systems

Operational precision and durability can significantly affect mission success in defense applications. As such, radiation hardened electronics are a strategic necessity in defense and military systems. hey are embedded in advanced missile systems, radar arrays, nuclear command and control units, and secure communication networks. Military satellities and avionics also rely heavily on these components for secure navigation and data encryption.

Nuclear Energy Facilities

Electronics around nuclear reactors are exposed to persistent levels of gamma radiation and neutron flux. Radiation hardened electronics play a crucial role in managing core monitoring systems, robotic inspection tools, and automated shutdown procedures. The resilience of these electronics ensures both operational stability and the safety of workers and communities.

View More Information @ https://www.polarismarketresearch.com/industry-analysis/radiation-hardened-electronics-market/request-for-sample

What Are Key Market Metrics?

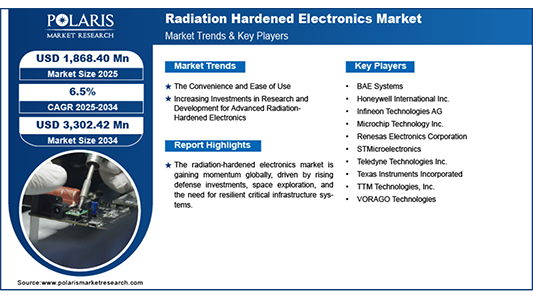

The latest report by Polaris Market Research examines the radiation hardened electronics market to register a CAGR of 6.5% during the projection period, 2025 to 2034. The market was valued at USD 1,812.57 million in 2024 and is projected to grow to USD 3,302.42 million by 2034.

What’s Fueling Market Growth?

Several factors are driving the radiation hardened electronics market growth. These include:

Expanding Space Programs and Satellite Deployments

The surge in space exploration has significantly elevated the demand for radiation hardened systems. Whether it’s lunar landers or Mars-bound rovers, these missions require robust electronics that can withstand deep-space radiation and extreme thermal fluctuations. Moreover, the proliferation of CubeSats and nanosatellites relies on miniaturized rad-hard processors and power management chips that can operate reliably without failover or human intervention.

Modernization of Military and Defense Systems

Global defense strategies are evolving to include advanced warfare scenarios, which necessitate electronic systems capable of operating in high radiation conditions. Defense modernization programs in the U.S., NATO, and parts of Asia Pacific are prioritizing resilient systems for missile defense, tactical communications, and command-and-control infrastructures. Radiation hardened electronics are integral to these systems, as they ensure continuity of mission even during high-altitude nuclear detonations or electromagnetic pulse events.

What Are Emerging Market Trends?

Here’s a look at some of the key trends shaping the radiation hardened electronics market landscape:

AI Integration and Edge Processing in Space: The deployment of AI systems in satellites and rovers has created a need for radiation hardened AI accelerators and neuromorphic chips that can compute at the edge.

Dual-Use Technologies: Many radiation hardened technologies are now being adapted from military to commercial use. This is expanding the customer base and stimulating innovation in avionics, mining, and medical imaging.

Modular and COTS-Based Solutions: The shift toward hardened commercial off-the-shelf (COTS) components is helping reduce costs while maintaining acceptable radiation resistance. Modular solutions also simplify system upgrades.

Conclusion

Radiation hardened electronics are no longer limited to niche government missions. They are becoming vital to a broader ecosystem of connected and safety-critical systems. Whether powering rovers on Mars or guiding autonomous military platforms, these electronics represent the intersection of resilience and innovation.