In the realm of powerful light, where precision meets raw power, a quiet revolution has been unfolding. Gone are the days of clunky, inefficient lasers that demanded vast amounts of energy and space. The spotlight has now shifted to a more elegant, formidable, and versatile technology: the fibre laser. This isn’t just an incremental improvement; it’s a fundamental reimagining of laser technology that is transforming everything from delicate surgery to heavy-duty manufacturing.

The Heart of Light: Understanding the Fibre Difference

At its core, a fibre laser is a device where the very medium that generates the laser beam is an optical fibre—a hair-thin strand of glass doped with rare-earth elements like ytterbium or erbium. This elegant design is its greatest strength. Unlike traditional lasers that use gases or crystals and require complex mirror systems to bounce light around, the fibre laser confines and amplifies its light within this flexible glass core. Think of it as the difference between trying to channel a raging river through a wide, open delta versus guiding a powerful, focused torrent through a high-pressure hose. This fundamental architecture leads to a beam of exceptional quality, stability, and efficiency.

A Symphony of Advantages: Why Industry Embraced the Light

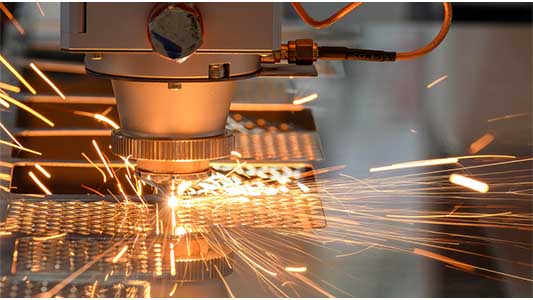

The shift to fibre laser technology is driven by a compelling symphony of benefits that speak directly to the demands of modern engineering. Their superior efficiency is often the first note heard; they convert electrical power into laser light with remarkable effectiveness, significantly reducing operating costs and cooling requirements. This efficiency is matched by an unparalleled beam quality that delivers a perfectly focused, consistent spot of energy. This allows for breathtaking precision, enabling manufacturers to cut intricate patterns in sheet metal, weld delicate medical components, or mark serial numbers with permanent, microscopic clarity.

Furthermore, their solid-state design, with the gain medium encapsulated within a flexible fibre, makes them incredibly robust and virtually maintenance-free. They are immune to misalignment from vibrations or temperature fluctuations—a common headache with older laser types. This reliability translates into less downtime and higher productivity on the factory floor. Combined with their compact footprint, which allows for easy integration into robotic arms and automated production lines, fibre lasers have become the indispensable workhorse of advanced manufacturing.

From Micro to Macro: The Expansive Realm of Applications

The versatility of fibre lasers is perhaps their most astonishing feature. Their power can be precisely tuned and their wavelengths selected to interact with a vast array of materials, making them a universal tool. In the world of macro-processing, high-power fibre lasers dominate metal cutting and welding, slicing through thick steel with ease while leaving clean, burr-free edges that require no finishing. They are transforming automotive and aerospace production, where strength and weight are paramount. On the other end of the spectrum, their precision enables micro-machining tasks that border on the artistic. They drill impossibly small holes in turbine blades for cooling, ablate thin layers for solar panel production, and create intricate stents for medical applications. In the field of telecom