Thermoelectric coolers, or Peltier coolers, are devices that serve as a unique method of temperature control. This is achieved with the help of semiconductors and electricity, which transmit heat away from the objects that are heating up. In contrast to conventional cooling systems, thermoelectric coolers do not make use of refrigerants and compressors, instead they utilize electric power to generate a cooling effect by transferring heat from one side of a thermoelectric module to another. This is known as the Peltier effect of heat transfer, which not only eliminates the need for moving parts but also mitigates the emission of harmful gases, thereby minimizing environmental impact.

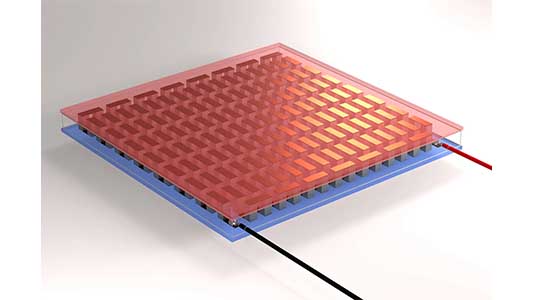

A thermoelectric cooler is a compact, small, square-shaped device, which is the size of a palm. The device is equipped with n-type and p-type semiconductors, which are electrically connected in a series and each is soldered to a metal interconnect, such as copper. Once the cooler is connected to a power source, a cooling effect is generated by transmitting heat from one side to another. Thus, this cooler has emerged as an ideal solution for efficient temperature management, making it useful for a wide range of applications.

Increasing Applicability of Thermoelectric Coolers

According to Allied Market Research, the thermoelectric coolers market is projected to garner $1,321.1 million by 2030 from $569.0 million in 2020, exhibiting a CAGR of 8.7% from 2021 to 2030. This revenue growth is majorly attributable to factors such as rise in trend of miniaturization and increase in penetration of electric vehicles (EVs). Thermoelectric coolers are composed of minimal moving parts and offer solid-state, compressor-free cooling, which makes it ideal to design portable and miniaturized devices. As the demand for compact electronics is growing at a notable pace, the demand for thermoelectric coolers is increasing simultaneously.

Furthermore, key advantages of thermoelectric coolers are their lightweight and compact size. This enable their integration in the thermal management system of EVs without notably increasing the overall weight of the vehicles. In contrast to traditional cooling systems that are equipped with refrigerants and moving parts, thermoelectric coolers do not comprise any moving parts, which make them highly durable and less susceptible to failures. They also contribute to enhancing the service life of EVs and minimize the frequent need for replacements and maintenance.

Moreover, solid-state thermoelectric devices exhibit higher efficiency as compared conventional cooling systems. This is attributed to the fact that they can achieve higher cooling levels with lower energy consumption, thereby minimizing the overall consumption of energy and improving vehicle efficiency. A new study published by the International Energy Agency, a Paris-based autonomous intergovernmental organization, stated that the sale of EVs reached around 3 million in the first quarter of 2024, which was around 25% higher than 2023. Furthermore, according to latest industry findings, of all the passenger cars sold in the U.S., EVs are projected to make up 25–30% of this total by the end of 2030. Thus, with increase in demand for EVs, the need for thermoelectric devices is anticipated to surge significantly. As the proliferation of EVs is increasing, scientists are focusing on designing new materials and developing advanced strategies to improve the performance and efficiency of thermoelectric devices. For instance, researchers are discovering the potential of nano-structured materials and optimizing the design of the device to boost its efficiency.

Assessing the Advantages of Thermoelectric Coolers

Thermoelectric coolers offer a wide range of benefits, for instance, they do not comprise any moving parts, which reduce the risk of wear and tear, thereby enhancing their reliability and minimizing the need for regular maintenance. In addition, unlike conventional cooling systems that have orientation limitations due to gravity, thermoelectric cooling devices can operate optimally in any orientation, as there are no restrictions on their deployment. Furthermore, maximum cooling systems do not have the capability to operate under zero gravity conditions or high acceleration forces. On the other hand, these conditions do not affect thermoelectric cooling devices, which make them suitable for use in a myriad of environments such as high-G applications and space.

In contrast to vapor compression cooling systems that emit greenhouse gases, these coolers do not produce such gases, making them a sustainable approach. One of the most significant advantages it their dual purpose of heating and cooling. If an application needs both cooling and heating, heating is achieved by using one technology like electric heater, whereas cooling requires other device such as vapor compression refrigerator. Contrarily, thermoelectric coolers can attain both heating and cooling merely by reversing electric currents, thus serving as a cost-effective solution. As multiple benefits are associated with thermoelectric coolers, their adoption is expected to increase across multiple applications in the coming years.

In a Nutshell

Applications that require both heating and cooling use separate technologies, for instance, electric heaters for heating and vapor compression systems for cooling. In contrast, thermoelectric coolers have emerged as an advanced module that has the capability to achieve both heating and cooling just by reversing electric currents. Moreover, they offer multiple advantages, including high reliability and durability due to no moving parts, operational in any orientation, no greenhouse gas emissions, and compact size. With increase in proliferation of EVs, the need for thermoelectric coolers is expected to increase. This is attributed to the fact that they serve as an integral part of EVs, as they can attain higher levels of cooling while significantly reducing energy consumption.